Rovema CMK Operator’s Manual

Section 5: Operator Controls

200246 CMK Operators Manual (02/06/2006) 5-33

HMI (Human-Machine-Interface)

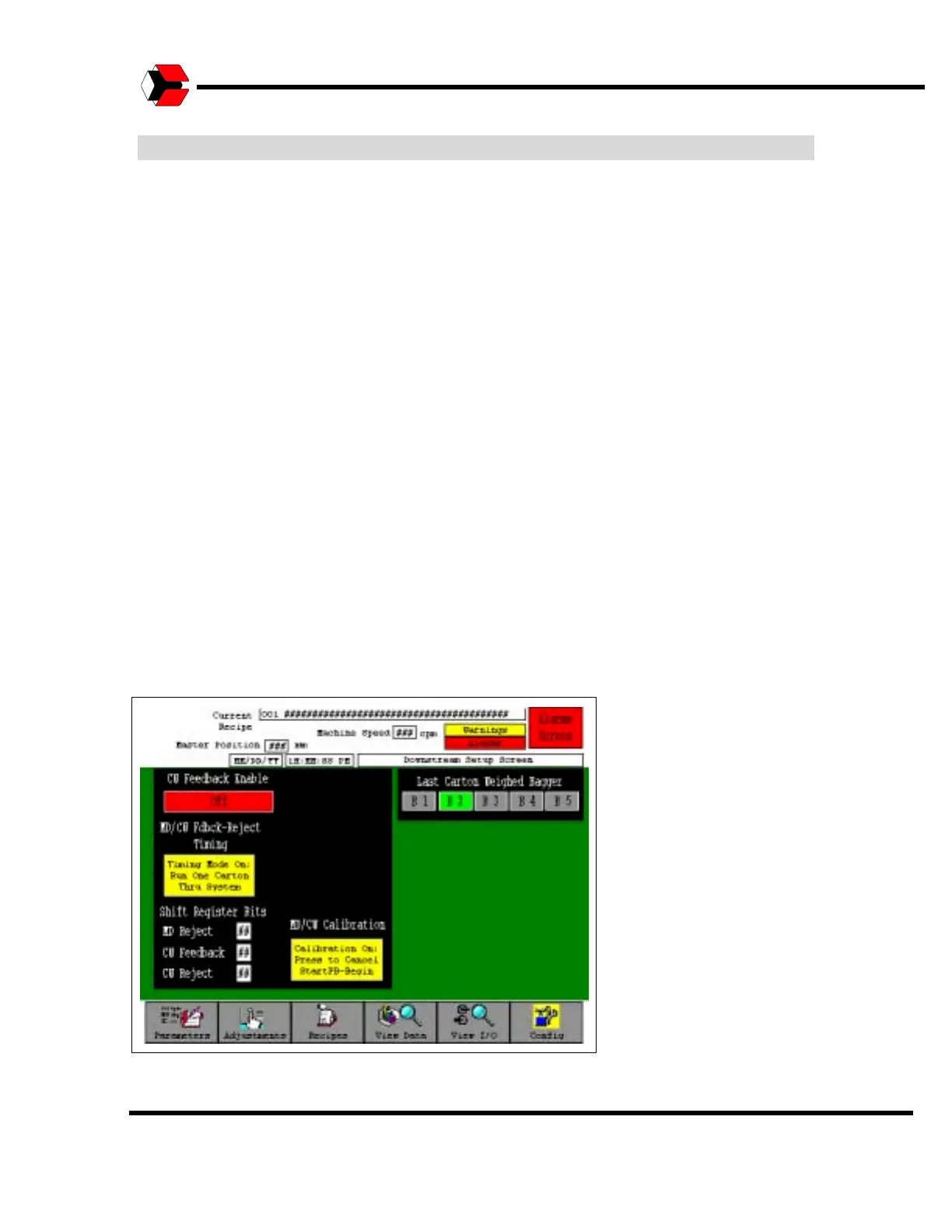

Downstream Setup Menu

The Downstream Setup screen is accessed from the Adjustments screen. This

screen allows you to set up communications with downstream equipment.

The “CU Feedback Enable” toggles between On and Off to determine if the cartoner

takes the carton weight feedback information from the checkweigher and sends

correction information to the baggers.

The “MD/CU Fdbk-Reject Timing” button may be set to Timing Mode On, to run one

carton thru the system in order to set the metal detect reject, checkweigher reject

and checkweigher feedback timing. This allows the system to track reject and weight

information to individual baggers. One carton must be sent through the system for

each of the three categories that need to be tracked. The Batch Control screen can

be used to send one carton worth of product from any bagger. A metal detect reject

of this carton must be triggered in order to calibrate the metal detect reject timing.

The same is true of a second carton for checkweigher reject. Any carton that runs

across the checkweigher will trigger weight feedback but one should be sent through

the system and not be rejected in order to ensure accuracy.

The “MD/CU Calibration” button may be set to Calibration mode. Calibration mode

disables the upstream permissives to all of the baggers, runs any remaining product

through the system until the cartoner is empty and then stops the cartoner while

leaving the discharge conveyors running. This allows test products to be sent across

the metal detector and checkweigher conveyors for calibration purposes. Normal

production will resume when Calibration mode is turned off.

Figure 5.39

Downstream Setup Screen

Loading...

Loading...