Rovema CMK Operator’s Manual

Section 5: Operator Controls

200246 CMK Operators Manual (02/06/2006) 5-13

HMI (Human-Machine-Interface)

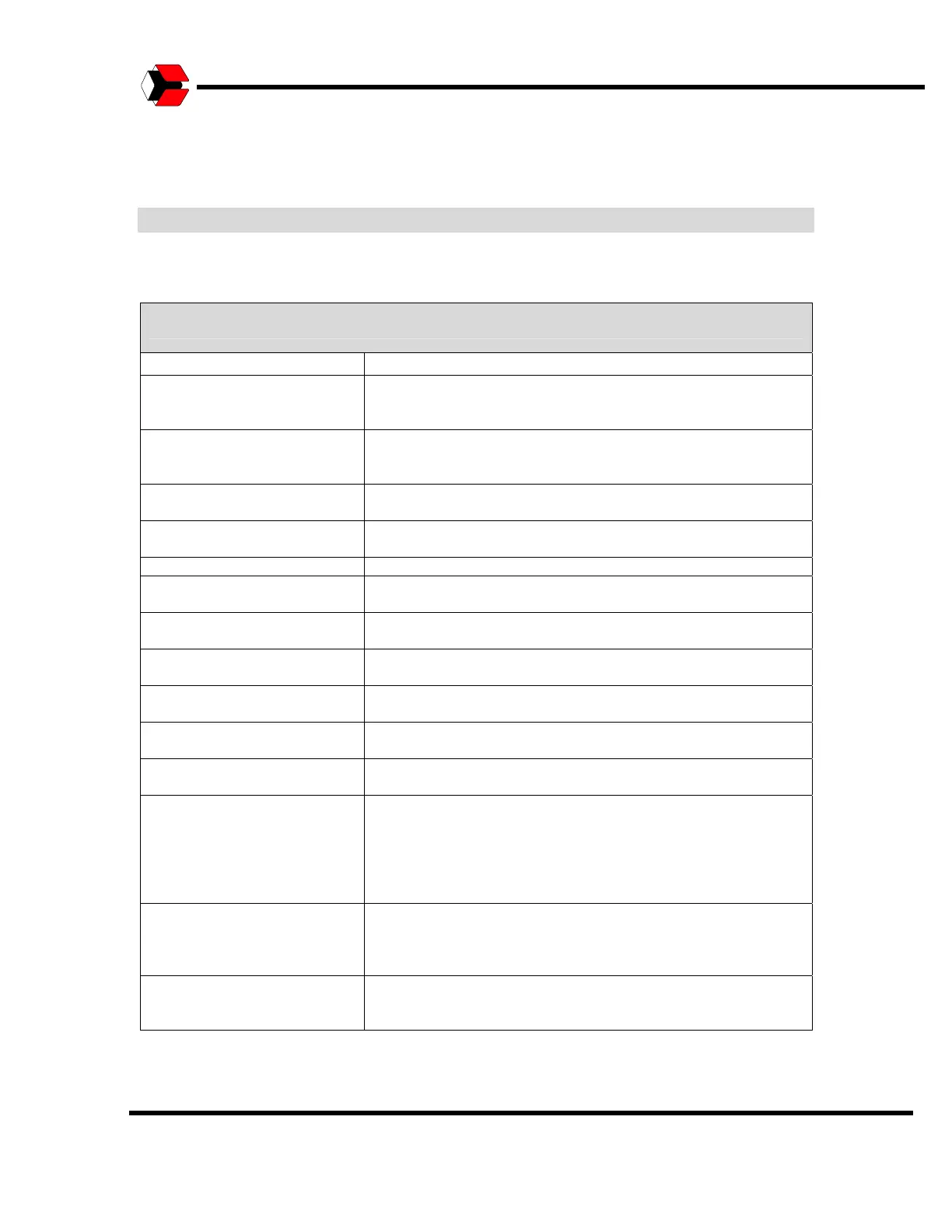

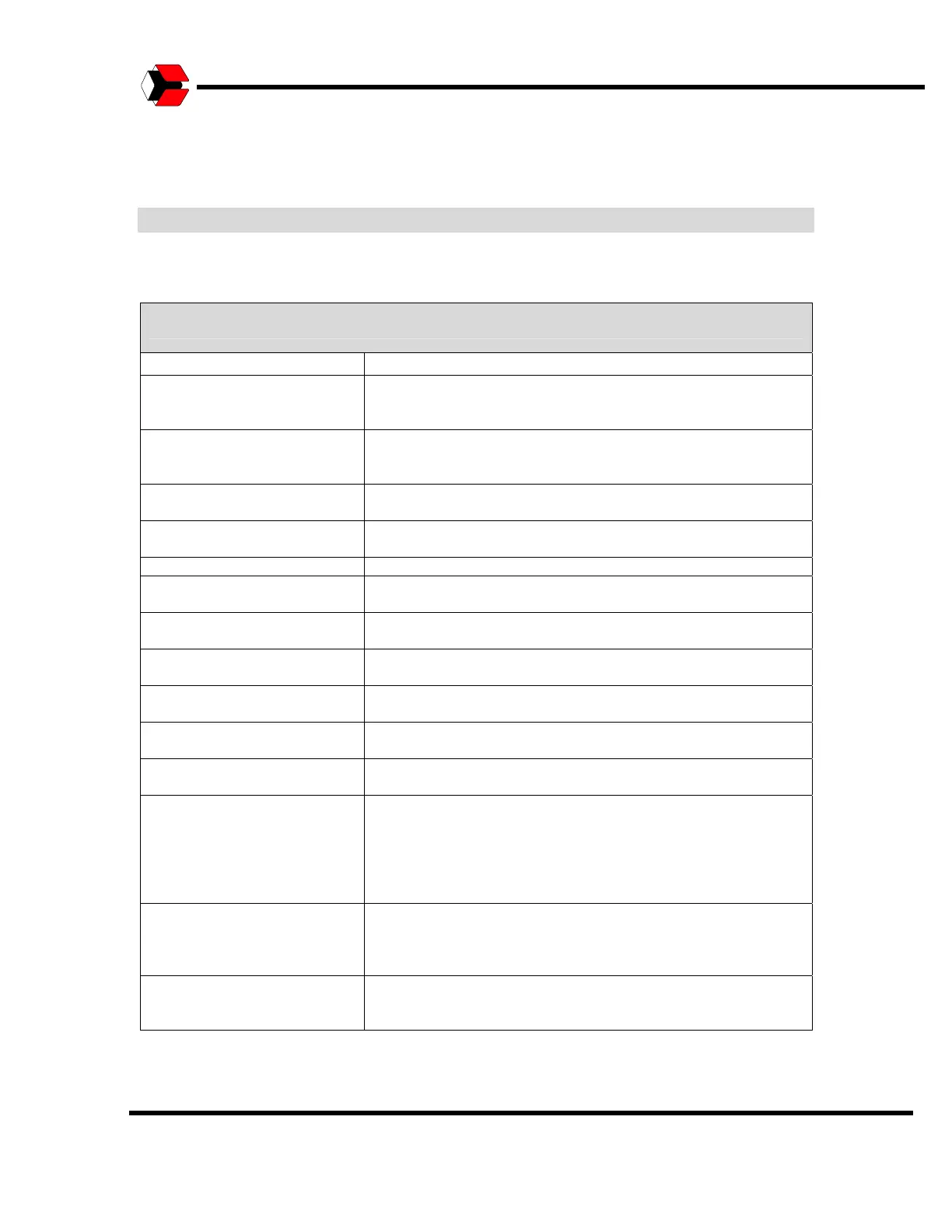

Cartoner PLS Parameters Descriptions

Cartoner PLS Parameters

Parameter Description

Product Detect Enable This determines if the product detect device will be used to

verify if there is product in the buckets of the bucket conveyor.

This is not used when in Batch mode.

Product Detect On Position

Product Detect Off Position

This determines the window that will be used each cycle to

determine whether or not there is product present in the

buckets.

Carton Release Enable This determines if a carton will be removed from the carton

magazine during production.

Carton Release Front On Pos

This determines when the Front Pusher is activated to push a

carton towards the Rear Pusher.

Carton Release Front Off Pos This determines when the Front Pusher is deactivated.

Carton Release Rear On Pos This determines when the Rear Pusher is activated to push

the carton blank out of the carton magazine.

Carton Release Rear Off Pos This determines when the Rear Pusher is deactivated to allow

the carton blank to be processed by downstream equipment.

Flap Lifter Enable This determines if the pneumatic flap lifter will be used during

production.

Flap Lifter On Position This determines when the flap lifter will move up to push the

upper flap in the upper guide rail.

Flap Lifter Off Position This determines when the flap lifter will move down to allow

the lower flap to go in the lower guide rail.

Product Load Enable This determines if product will be pushed into the cartons by

the Barrel Loader.

Load Enable/Disable On Pos

Load Enable/Disable Off Pos

This controls the timing of the Loader CAM Follower switch

solenoid valve. When the CAM Follower is switched from the

no-load track to the loader push track, and vice-versa, it must

be done at a certain point during the machine cycle in order to

avoid a mechanical jam. Once set, these parameters should

not be changed.

Jam Detect Rail Reset On

Jam Detect Rail Reset Off

This determines when the Jaw Jam Detect Reset sensor will

be used. This sensor is in the Barrel Loader and is used to

detect if there is a Jam or fault. If a product jam is present, the

Barrel Loader will raise to clear the jam or fault.

Open Flap Detect Enable This determines if the Open Flap Detector will be used during

production. When enabled, a carton is rejected from the

cartoner discharge conveyor if an open flap is detected.

Figure 5.16

Cartoner PLS Parameter Descriptions

Loading...

Loading...