FRONT AXLE

M6040, M7040, WSM

6-S18

Slip Torque of LSD Disc

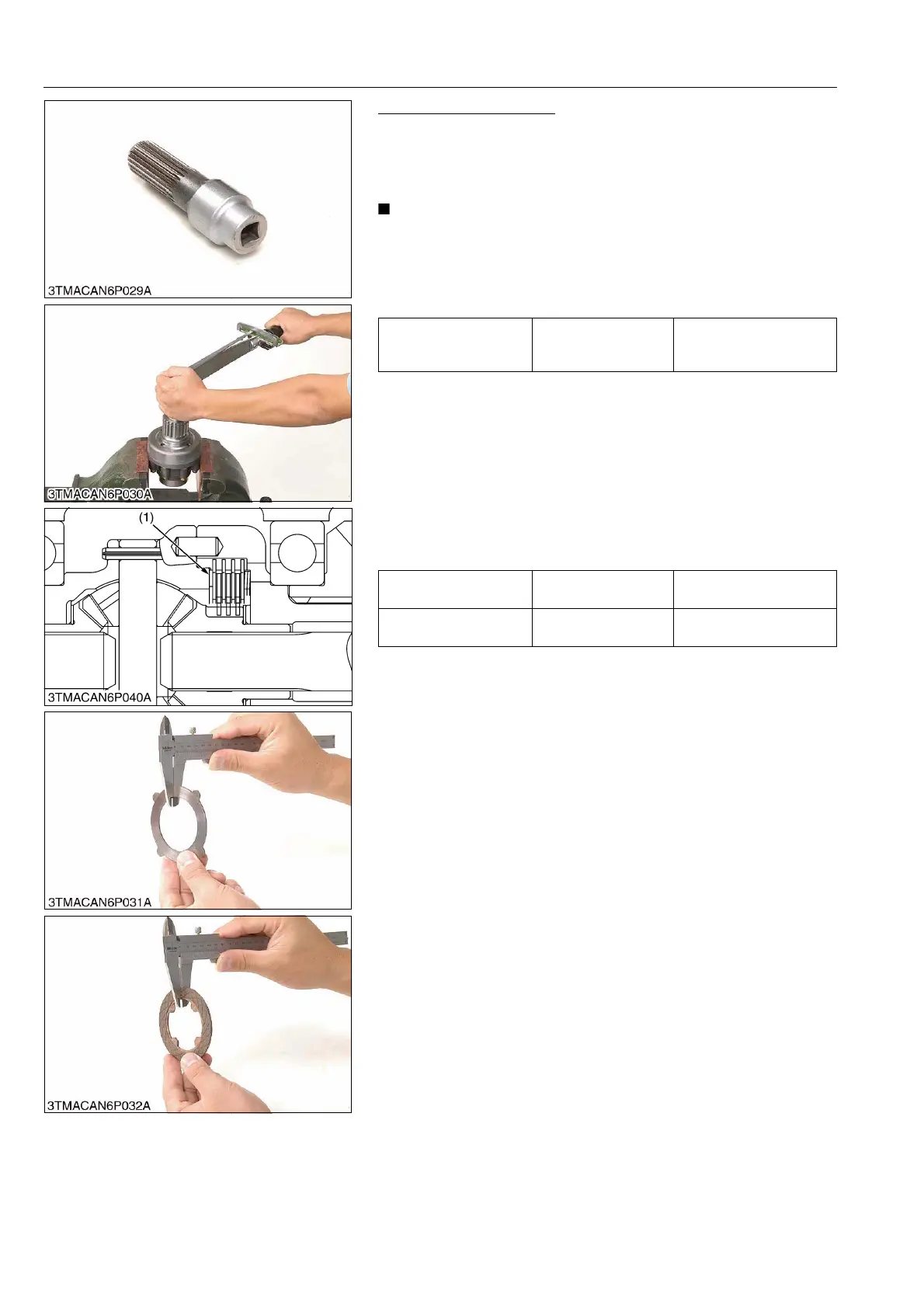

1. Set the differential assembly in the vice securely.

2. Check the LSD slip torque using a jig as shown in the photo.

3. If the LSD slip torque is not within the factory specification,

adjust with LSD shim (1).

• When measuring the slip torque for LSD, apply ample

lubricant to the LSD disc.

• Turn the LSD side gear using a jig to clockwise and

counterclockwise each direction several times to mesh the

LSD disc and steel plate.

(Reference)

• Jig in the photo is: Spline from yoke shaft and welded with box

wrench. (See page G-67.)

• Thickness of LSD shim:

0.1 mm (0.004 in.) [Code No.: 35533-43010]

0.2 mm (0.008 in.) [Code No.: 35533-43020]

0.4 mm (0.016 in.) [Code No.: 35533-43030]

0.8 mm (0.032 in.) [Code No.: 35533-43040]

1.0 mm (0.039 in.) [Code No.: 35533-43050]

1.2 mm (0.047 in.) [Code No.: 35533-43060]

• Slip torque changes per 0.1 mm (0.004 in.) shim:

Approx. 5 to 7 N·m (0.5 to 0.7 kgf·m, 3.6 to 5.1 lbf·ft)

9Y1210143FAS0029US0

LSD slip torque Factory specification

34 to 44 N·m

3.5 to 4.5 kgf·m

25.4 to 32.5 lbf·ft

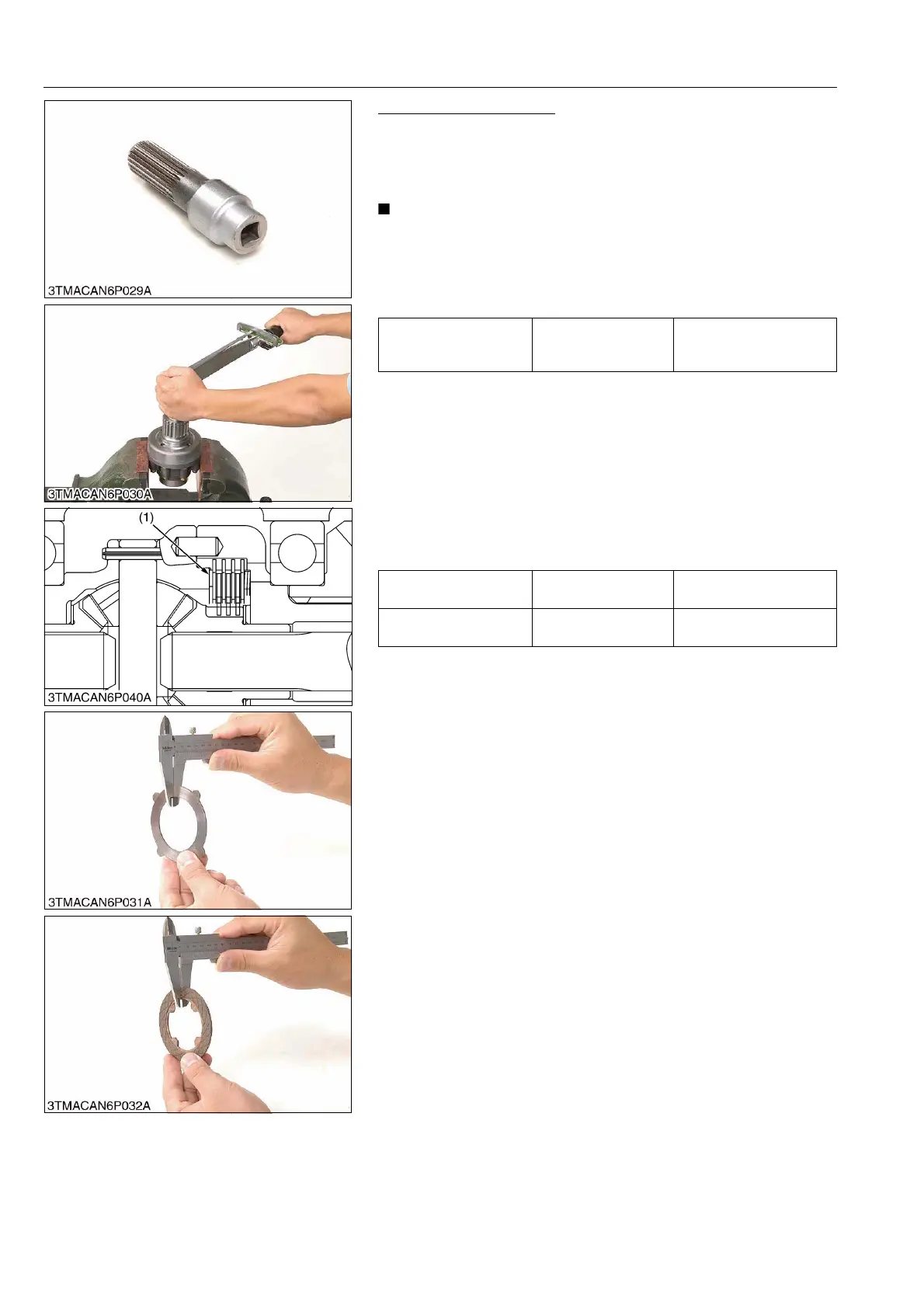

Thickness of steel plate Factory specification

1.32 to 1.48 mm

0.05197 to 0.05827 in.

Thickness of LSD disc Factory specification

2.55 to 2.65 mm

0.10039 to 0.10433 in.

(1) Shim

Loading...

Loading...