Startup Procedure and Test Run

4

4.10 Fine Tuning during Test Runs (Adjust the Control Function)

YASKAWA SIEPC71061705H GA700 Series Technical Manual 199

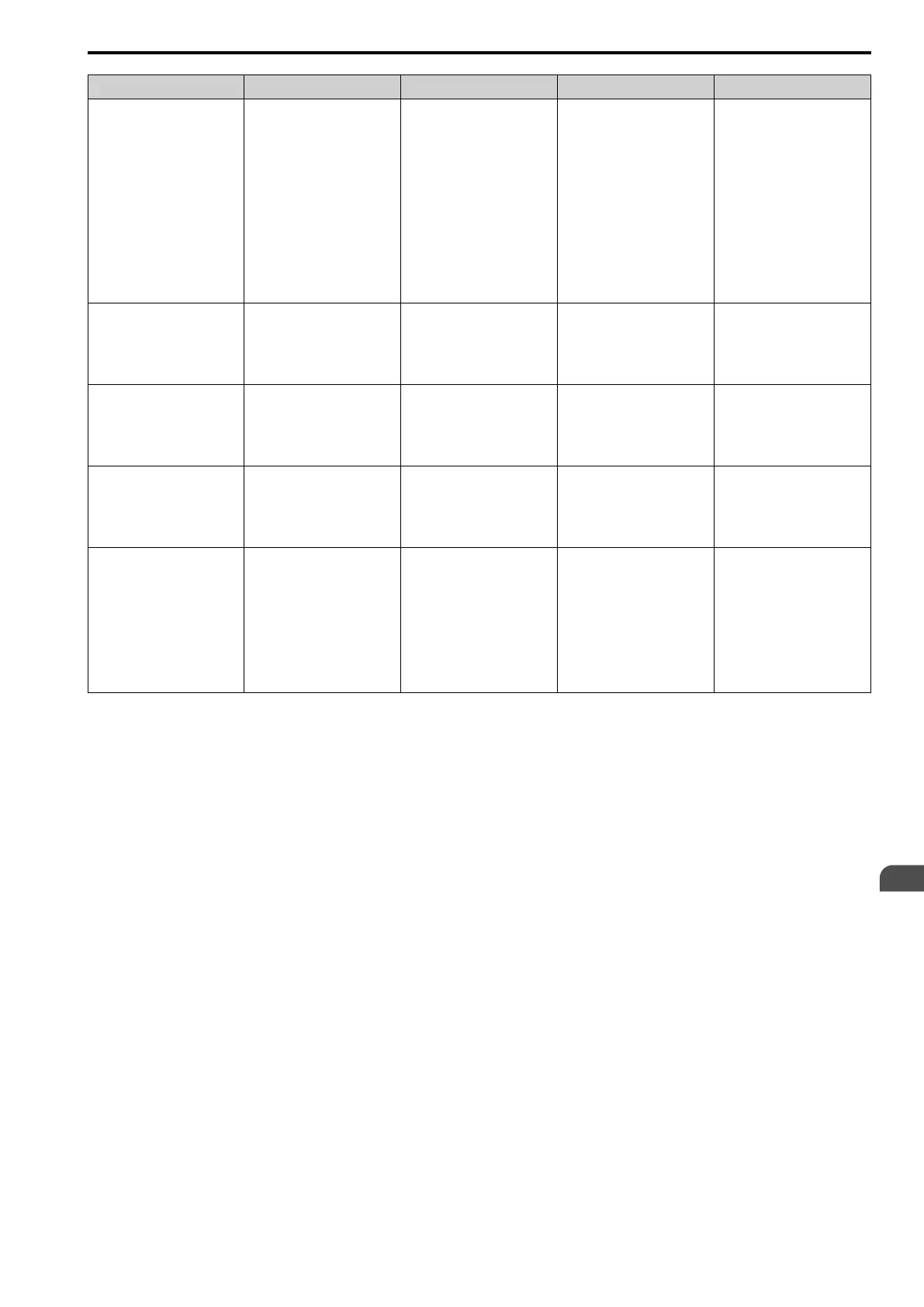

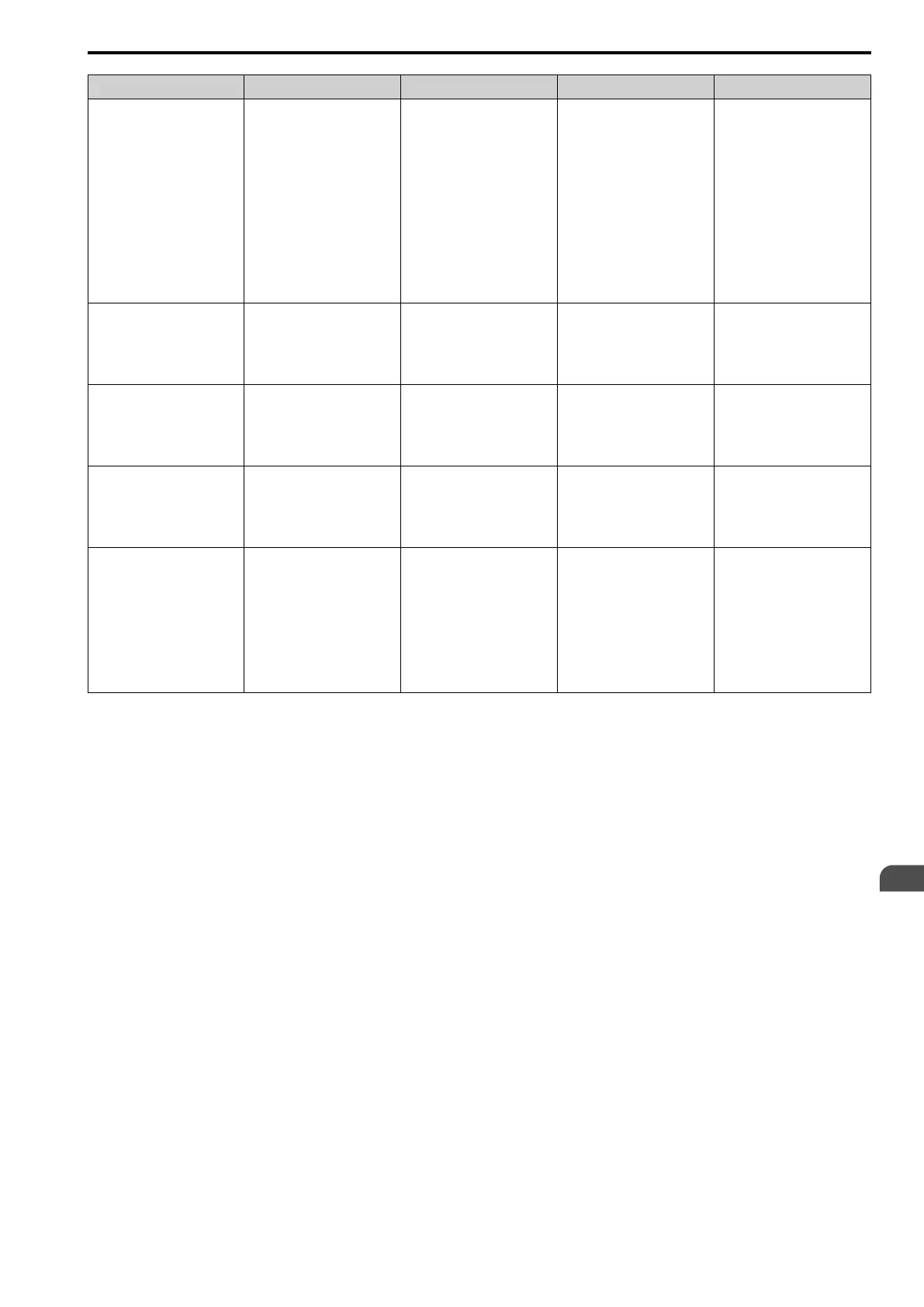

Issue Parameter Number Possible Solutions Default Recommended Setting

• Unsatisfactory motor torque

and speed response

• Hunting or oscillation

C4-02 [Torque Compensation

Delay Time 1]

• If torque or speed response are

slow, decrease the setting

value in increments of 2 ms.

• If hunting or oscillation occur,

increase the setting value in

increments of 10 ms.

Note:

Make sure that this parameter

setting is: C4-02 ≤ C4-06

[Motor 2 Torque Comp Delay

Time].

When you adjust C4-02, you

must also increase the n2-02

[SpdFeedbackDetCtr (AFR)

TimeConst1] value by the

same ratio.

20 ms

*1

20 ms to 100 ms

*1

• Speed response is slow.

• Speed is not stable.

C3-02 [Slip Compensation Delay

Time]

• If speed response is slow,

decrease the setting value in

increments of 10 ms.

• If speed is not stable, increase

the value in increments of 10

ms.

200 ms

*1

100 ms to 500 ms

Speed precision is unsatisfactory. C3-01 [Slip Compensation Gain]

• If speed is too slow, increase

the setting value in increments

of 0.1.

• If speed is too fast, decrease

the setting value in increments

of 0.1.

1.0

*2

0.5 - 1.5

• The volume of the motor

excitation sound is too high.

• Hunting or oscillation at low

speeds (10 Hz or lower)

C6-02 [Carrier Frequency

Selection]

• If the volume of the motor

excitation sound is too high,

increase the carrier frequency.

• If hunting or oscillation occur

at low speeds, decrease the

carrier frequency.

1 (2 kHz)

*3

0 to upper limit value

• Torque at low speeds (10 Hz

or lower) is not sufficient.

speed response is slow.

• Speed response is slow.

• Large initial vibration at start

up.

• E1-08 [Mid Point AVoltage]

• E1-10 [Minimum Output

Voltage]

• If torque or speed response are

slow, increase the setting

value.

• If there is large initial

vibration at start up, decrease

the setting value

Note:

If the setting value is set too

high, a large torque reference

may be output even with light

loads.

• E1-08: 11.0 V

*2

• E1-10: 2.0 V

*2

Default setting +/- 2 V

*4

*1 The default setting changes when the settings forA1-02 [Control Method Selection] and o2-04 [Drive Model (KVA) Selection]

change.

*2 The default setting changes when the settings for A1-02 [Control Method Selection] and E1-03 [V/f Pattern Selection] change.

*3 The default setting changes when the settings for C6-01 [Normal / Heavy Duty Selection] and o2-04 change.

*4 Recommended settings are for 200 V class drives. Multiply the voltage by 2 for 400 V class drives.

■ Precaution When You Use IE3 Premium Efficiency Motors

IE3 motors have different motor characteristics from IE1 and other motors. Set the parameters as specified by the

motor characteristics. If the drive detects oC [Overcurrent] or ov [Overvoltage] during speed search after the

drive restores power after a momentary power loss, set these parameters:

• b3-03 [Speed Search Deceleration Time] = default value × 2

• L2-03 [Minimum Baseblock Time] = default value × 2

• L2-04 [Powerloss V/f Recovery Ramp Time] = default value × 2

Loading...

Loading...