Standards Compliance

5

5.3 UL Standards

YASKAWA SIEPC71061705H GA700 Series Technical Manual 247

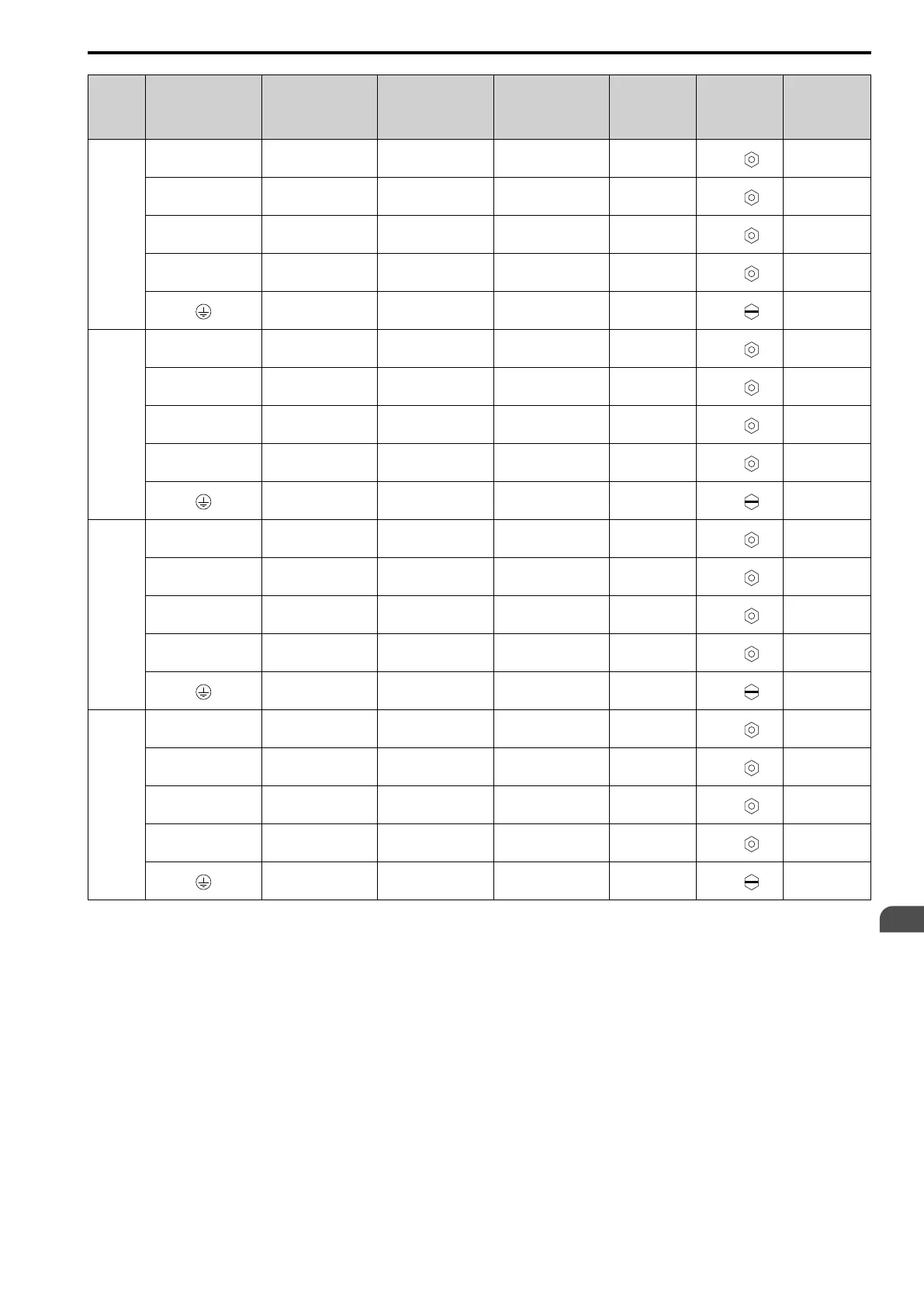

Model Terminal

Recomm. Gauge

AWG, kcmil

Applicable Gauge

AWG, kcmil

(mm

2

)

IP20 Applicable

Gauge

*1

AWG, kcmil

(mm

2

)

Wire Stripping

Length

*2

mm

Terminal Screw

Size and Shape

Tightening

Torque

N∙m (lbf∙in)

2257

R/L1, S/L2, T/L3 2/0 × 2P

3 - 4/0 × 2P

(25 - 95 × 2P)

2/0 - 4/0 × 2P

(70 - 95 × 2P)

-

M10

20

(177)

U/T1, V/T2, W/T3 2/0 × 2P

3 - 4/0 × 2P

(25 - 95 × 2P)

2/0 - 4/0 × 2P

(70 - 95 × 2P)

-

M10

20

(177)

-, +1 4/0 × 2P

2 - 250 × 2P

(35 - 120 × 2P)

4/0 - 250 × 2P

(95 × 2P)

-

M10

20

(177)

+3 1/0 × 2P

4 - 1/0 × 2P

(25 - 50 × 2P)

1/0 × 2P

(50 × 2P)

-

M10

20

(177)

3

3 - 350

(25 - 185)

- -

M10

18 - 23

(159 - 204)

2313

R/L1, S/L2, T/L3 4/0 × 2P

3 - 4/0 × 2P

(25 - 95 × 2P)

2/0 - 4/0 × 2P

(70 - 95 × 2P)

-

M10

20

(177)

U/T1, V/T2, W/T3 3/0 × 2P

3 - 4/0 × 2P

(25 - 95 × 2P)

2/0 - 4/0 × 2P

(70 - 95 × 2P)

-

M10

20

(177)

-, +1 250 × 2P

2 - 250 × 2P

(35 - 120 × 2P)

4/0 - 250 × 2P

(95 × 2P)

-

M10

20

(177)

+3 1/0 × 2P

4 - 1/0 × 2P

(25 - 50 × 2P)

1/0 × 2P

(50 × 2P)

-

M10

20

(177)

2

2 - 350

(35 - 150)

- -

M10

18 - 23

(159 - 204)

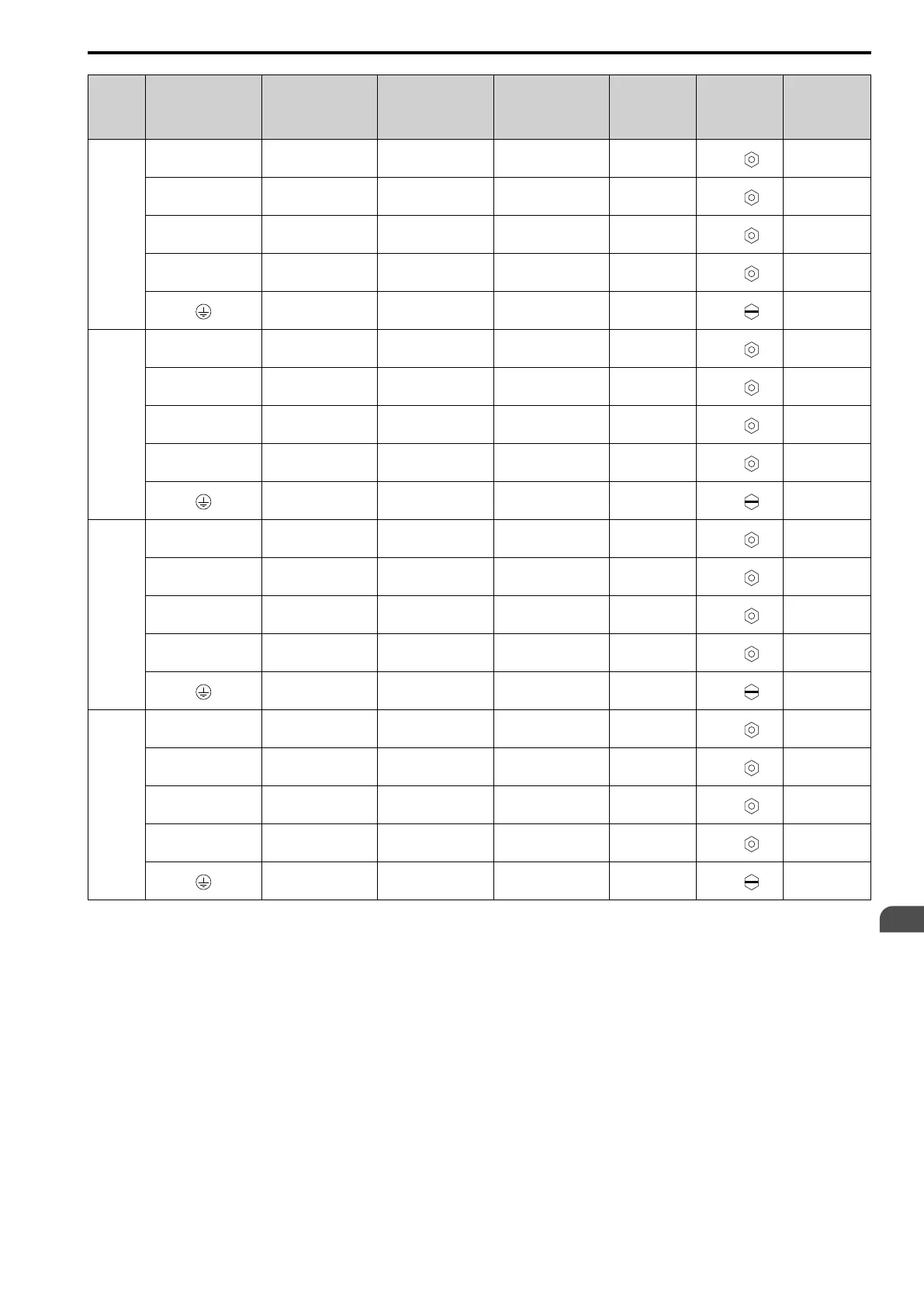

2360

R/L1, S/L2, T/L3 250 × 2P

2/0 - 300 × 2P

(70 - 150 × 2P)

250 - 300 × 2P

(120 - 150 × 2P)

-

M12

35

(310)

U/T1, V/T2, W/T3 250 × 2P

2/0 - 300 × 2P

(70 - 150 × 2P)

250 - 300 × 2P

(120 - 150 × 2P)

-

M12

35

(310)

-, +1 350 × 2P

4/0 - 400 × 2P

(95 - 185 × 2P)

300 - 400 × 2P

(150 - 185 × 2P)

-

M12

35

(310)

+3 3/0 × 2P

1/0 - 4/0 × 2P

(50 - 95 × 2P)

- -

M12

35

(310)

1

1 - 350

(50 - 150)

- -

M12

32 - 40

(283 - 354)

2415

R/L1, S/L2, T/L3 250 × 2P

2/0 - 300 × 2P

(70 - 150 × 2P)

250 - 300 × 2P

(120 - 150 × 2P)

-

M12

35

(310)

U/T1, V/T2, W/T3 300 × 2P

2/0 - 300 × 2P

(70 - 150 × 2P)

250 - 300 × 2P

(120 - 150 × 2P)

-

M12

35

(310)

-, +1 350 × 2P

4/0 - 400 × 2P

(95 - 185 × 2P)

300 - 400 × 2P

(150 - 185 × 2P)

-

M12

35

(310)

+3 3/0 × 2P

1/0 - 4/0 × 2P

(50 - 95 × 2P)

- -

M12

35

(310)

1

1 - 350

(50 - 150)

- -

M12

32 - 40

(283 - 354)

*1 For IP20 protection, use wires that are in the range of applicable gauges.

*2 Remove insulation from the ends of wires to expose the length of wire shown.

*3 For wire gauges more than AWG 8, tighten to a tightening torque of 4.1 N∙m to 4.5 N∙m (36 lbf∙in to 40 lbf∙in).

*4 Terminals - and +1 have two screws. The Recommended Gauge is the wire gauge for one terminal.

*5 A junction terminal is necessary to connect a braking unit (CDBR-series) to terminals - and +3.

Loading...

Loading...