Troubleshooting and fault elimination

F ault messages

8-6

L

EDSVS9332P-E EN 3.0

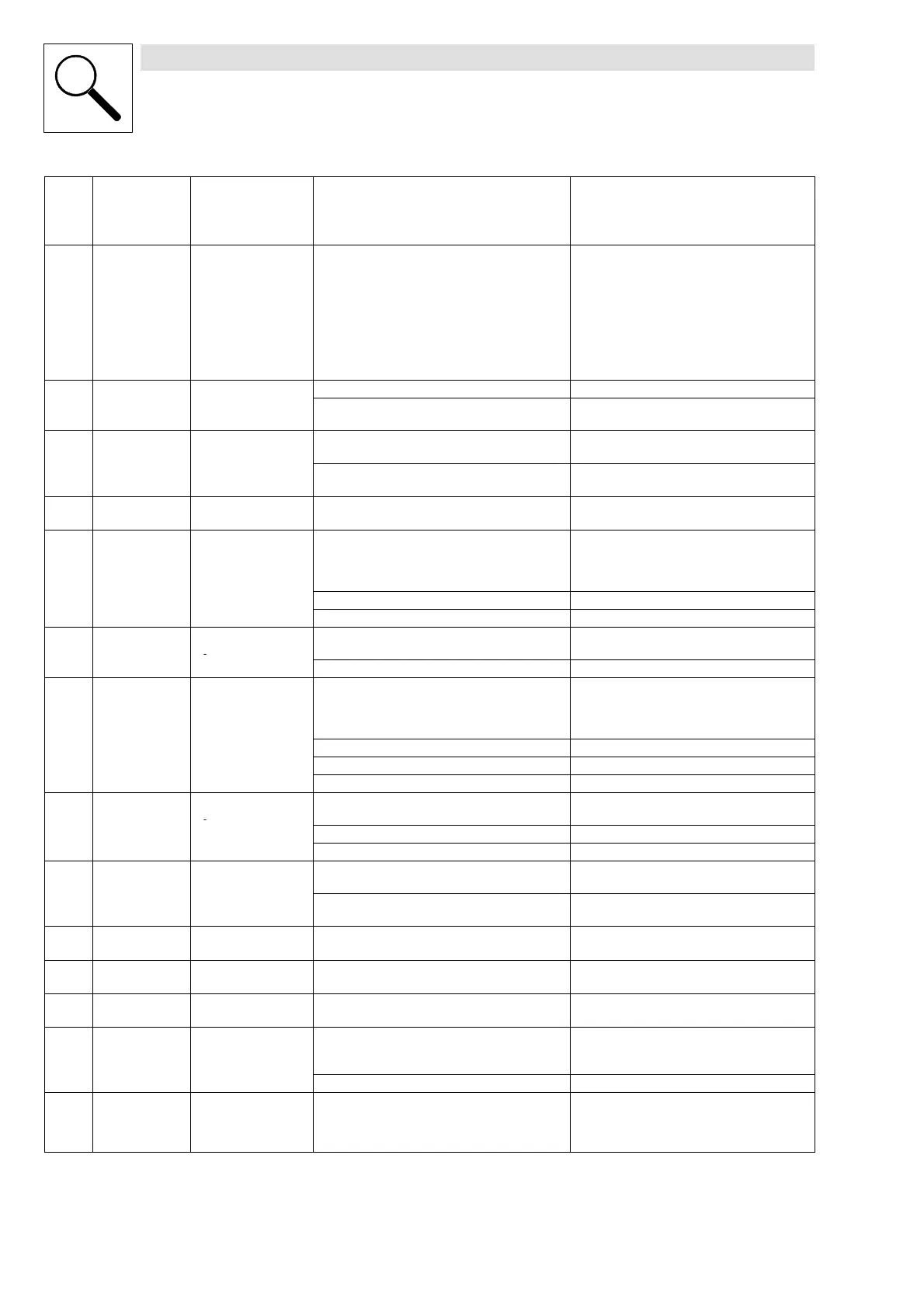

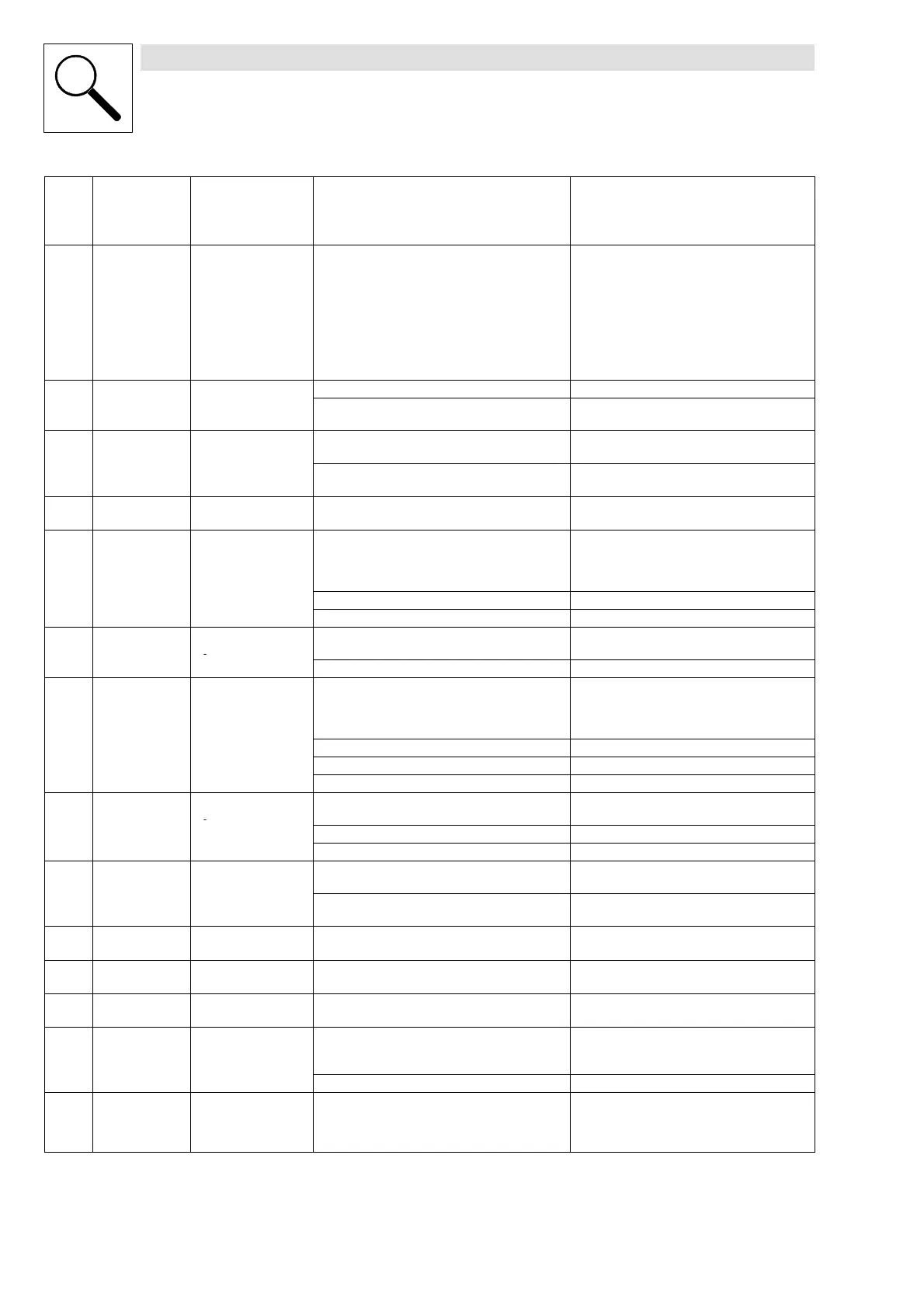

Display RemedyCauseError

Error number

x=0:TRIP

x=1:Message

x=2:Warning

x = 3: FAIL-QSP

nErr x190 Difference between

actual speed and speed

setpoint exceeds set

tolerance limits (C0576).

1. Motor torque not high enough

2. Mechanical drive overload

3. Error in encoder system / speed encoder defective

4. Tolerance too low (C0576)

1. Check limit values

2. Reduce mechanical load / adapt setpoint and

quick stop ramp

3. Check speed encoder and replace if necessary

4. Increase tolerance window . The nErr window

should be at least twice as big as for normal

operation.

•

TIP: If you want to monitor the speed encoder,

the error response should be set as TRIP.

OC1 x011 Short circuit

Short-circuit. Find out cause of short-circuit; check cable.

Excessive capacitive charging current of the motor

cable.

Use motor cable which is shorter or of lower

capacitance.

OC2 x012 Earth fault

One of the motor phases has earth contact.

•

Check motor

•

Check supply module

Excessive capacitive charging current of the motor

cable.

Use motor cable which is shorter or of lower

capacitance.

OC5 x015 I x t overload Frequent and overlong acceleration with overcurrent

Continuous overload with I

motor

>1.05xI

rx.

Check drive dimensioning.

OH x050 Heatsink temperature is

higher than the value set

in the controller

Ambient temperature T

amb

>40°Cor50°C.

•

Allow controller to cool and ensure better

ventilation.

•

Check ambient temperature i n the control

cabinet.

Heatsink very dirty. Clean heatsink

Incorrect mounting position. Change mounting position.

OH3

3)

x053 Heatsink temperature is

higher than the value set

Motor too hot because of excessive current or

frequent and overlong acceleration

Check drive dimensioning.

in the controller

No PTC connected. Connect PTC or switch-off monitoring (C0583=3).

OH4 x054 Heatsink temperature is

higher than the value set

under C0122.

Ambient temperature T

amb

>40°Cor50°C.

•

Allow controller to cool and ensure better

ventilation.

•

Check ambient temperature i n the control

cabinet.

Heatsink very dirty. Clean heatsink

Incorrect mounting position. Change mounting position.

Value set under C0122 was too low. Enter hi gher value.

OH7

3)

x057 Motor temperature is

higher than the value set

Motor too hot because of excessive current or

frequent and overlong acceleration

Check drive dimensioning.

under C0121.

No PTC connected. Connect PTC or switch-off monitoring (C0584=3).

Value set under C0121 was too low. Enter hi gher value.

OH8 x058 PTC at terminals T1, T2

indicates motor

Motor too hot because of excessive current or

frequent and overlong acceleration

Check drive dimensioning.

overheat.

Terminals T1, T2 are not assigned. Connect PTC or thermostat or switch off

monitoring (C0585=3).

OU x020 Overvoltage Excessive brake energy (DC bus vol tage higher than

set under C0173).

Use brake module or energy recovery module.

P01

1)

x151 Negative limit s witch Negative limit switch was reached.

•

Control drive in positive direction

•

Check terminal connec tion X5/E2.

P02

1)

x152 Positive limit s witch Positive limit switch was reached.

•

Control drive in negative directio n

•

Check terminal connec tion X5/E1.

P03 x153 First following error

Phase difference between set and actual position is

larger than the contouring error limit set under

C0255.

•

Extend contouring error limit under C0255

•

Switch off the monitoring if necessary

(C0589 = 3).

Drive cannot follow the digital frequency (I

max

limit). Check drive dimensioning.

P04

1)

x154 Negative position limit Negative position limit (C1224) was not reached. Find out why the value was not reached (e.g.

”incorrect” position targets, set function position

value) and adjust the negative position limit

(C1224) if necessary.

Loading...

Loading...