215575 247 Revision B

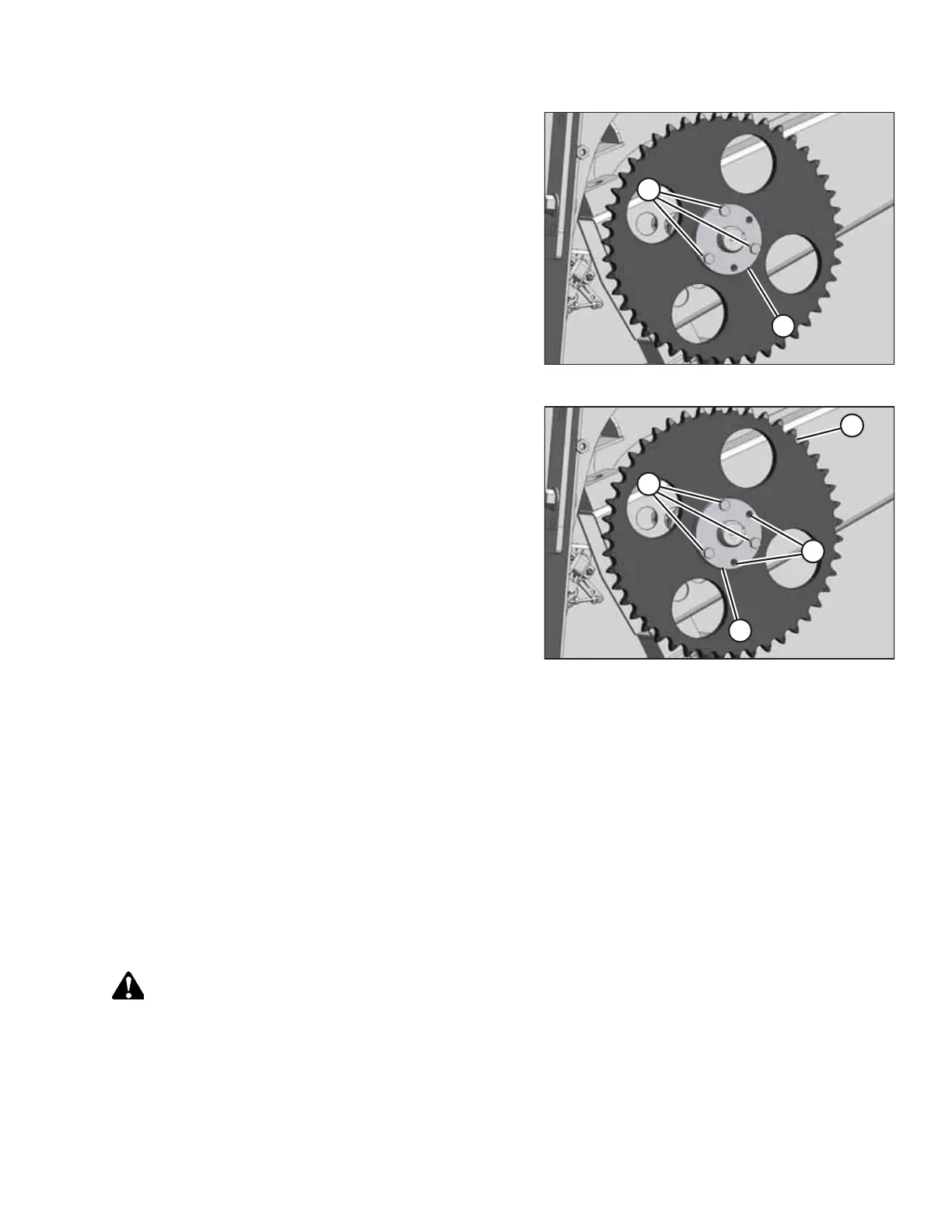

Figure 5.61: Driven Sprocket

8. Torque three M10 hex bolts (A) in equal increments to

44 Nm (32 lbf·ft) while maintaining the alignment between

the sprockets.

9. Tap bushing (B) with a hammer and torque the bolts again.

Repeat this step three times or until the bolts no longer

turn at 44 Nm (32 lbf·ft).

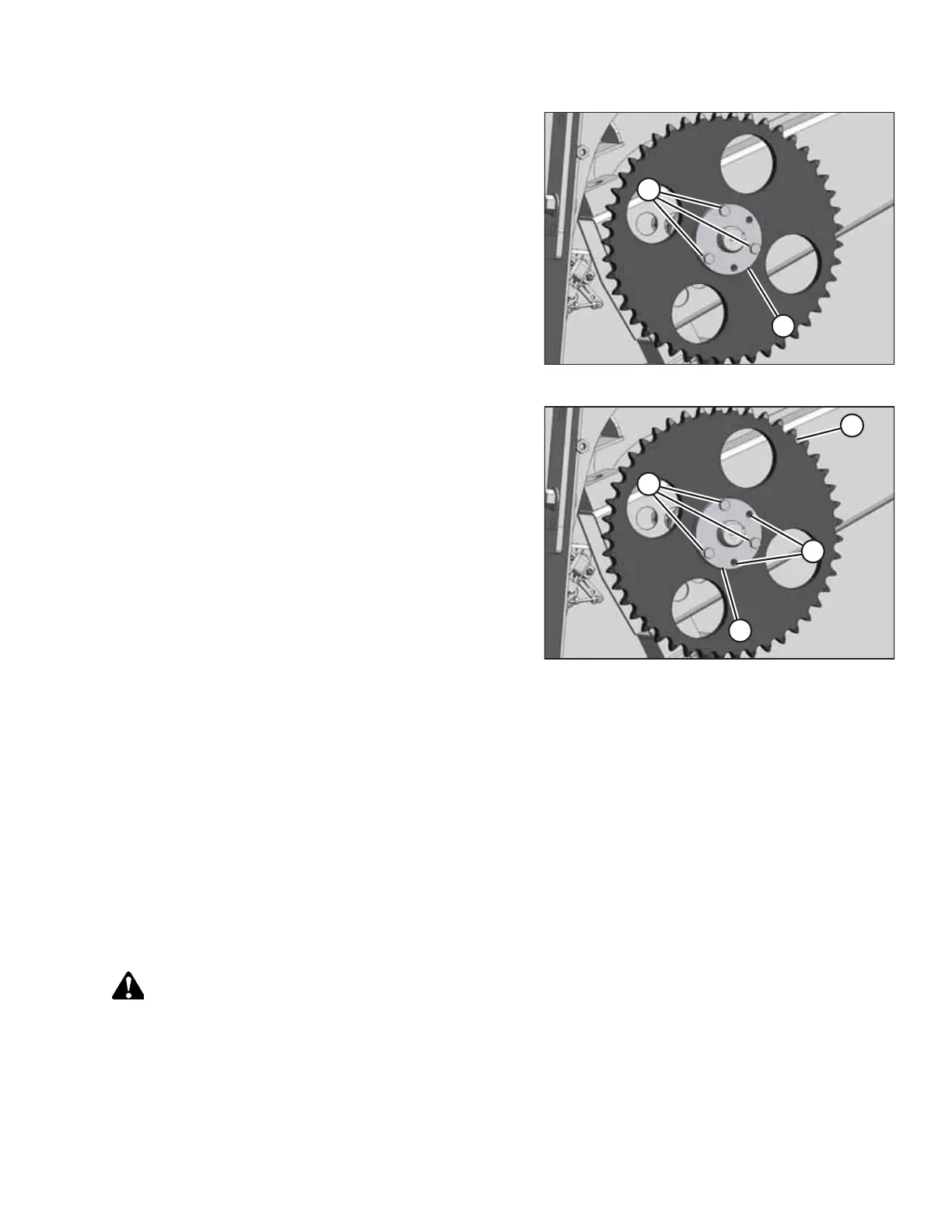

Figure 5.62: Driven Sprocket

10. Check the alignment of the sprockets again. If the

alignment is off by more than 1 mm (3/64 in.), follow these

steps:

a. Measure and record the position of tapered

bushing (D) relative to the driveshaft.

b. Remove three M10 hex bolts (A) from tapered

bushing (D).

c. Reinstall two M10 hex bolts (A) into threaded holes (B)

in tapered bushing (D).

d. Alternately turn M10 hex bolts (A) into tapered

bushing (D) in half-turn increments until the tapered

bushing and sprocket (C) can be moved.

e. Reposition tapered bushing (D) to account for the

misalignment.

f. Repeat Step 5, page 246 to Step 10, page 247.

g. Check the sprocket’s alignment.

h. Repeat Step 10, page 247 until the sprockets are in

alignment.

11. Install and tension the chain. For instructions, refer to Installing Auger Drive Chain, page 243.

12. Close the left endshield. For instructions, refer to 3.3.2 Closing Left Endshield, page 26.

Removing Drive Sprocket

If the header is not attached to the combine, you will have to lock the rotation of the driven sprocket to remove the drive

sprocket.

WARNING

To avoid bodily injury or death from unexpected startup of machine, always stop the engine and remove the key from

the ignition before leaving the operator’s seat for any reason.

1. Lower the header to the ground.

2. Shut down the combine and remove the key from the ignition.

MAINTENANCE AND SERVICING

Loading...

Loading...