A-1

FX Series PLC User's Manual - Data Communication Edition

Common Items

1 Introduction

1.1 Communication Types

A

Common Items

B

N:N Network

C

Parallel Link

D

Computer Link

E

Inverter

Communication

F

Non-Protocol

Communication

(RS/RS2 Instruction)

G

Non-Protocol

Communication

(FX

2N

-232IF)

H

Programming

Communication

I

Remote

Maintenance

Apx.

Discontinued

models

1. Introduction

This manual explains the communication types supported by FX PLCs.

This chapter explains the serial communication (in accordance with RS-232C, RS-485/RS-422), various link

communication types, etc. and states the applicable FX PLCs.

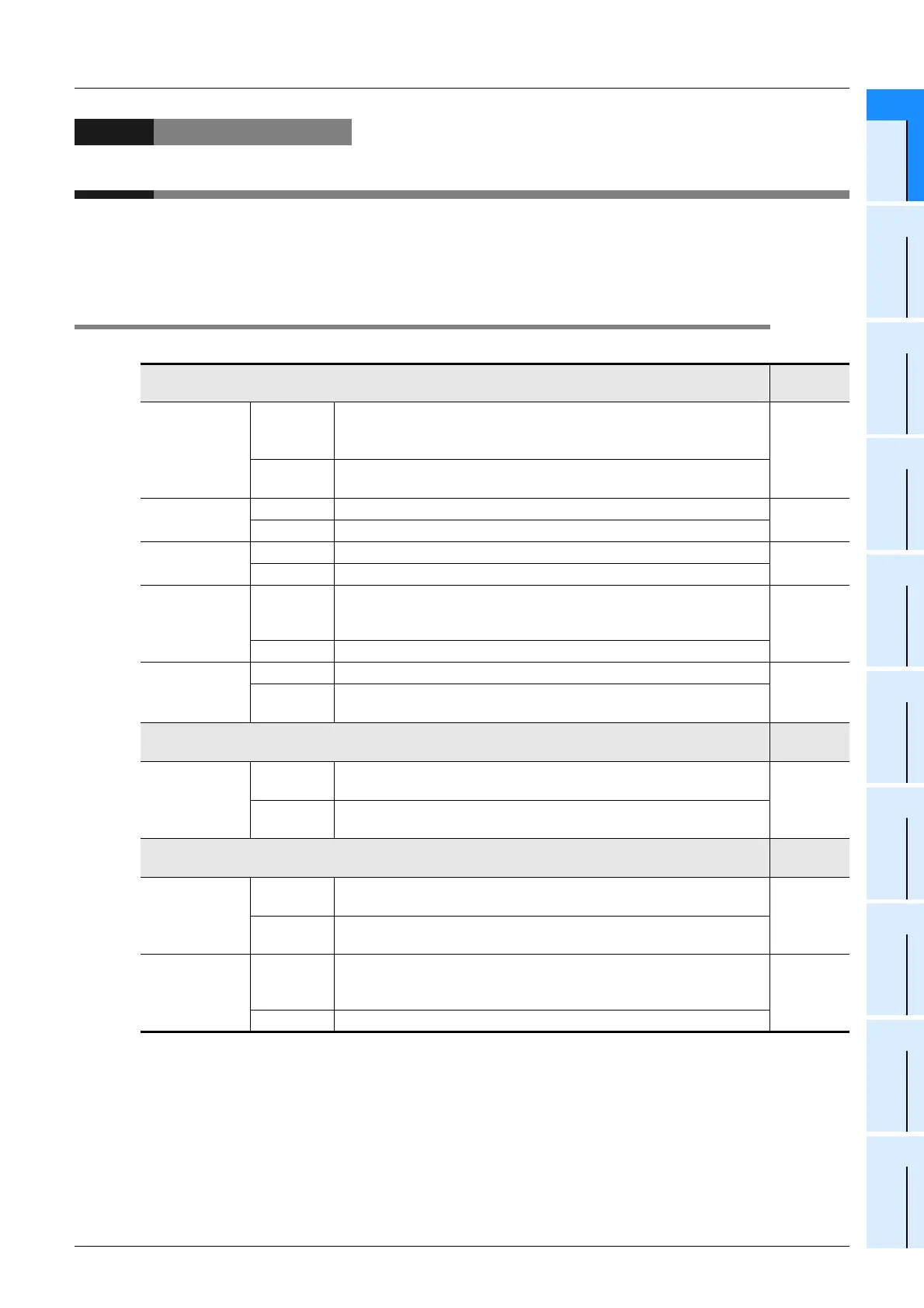

1.1 Communication Types

The table below shows the communication types supported by the FX Series.

Link

Reference

subsection

CC-Link

Function

• Connects FX PLCs as remote device stations to the CC-Link system

whose master station is a MELSEC A/QnA/Q PLC.

• Constructs a CC-Link system whose master station is an FX PLC.

1.2.1

Application

Line control in the decentralized or centralized method and information

transfer from/to the host network.

N:N Network

Function Easily enables data link between FX PLCs.

1.2.2

Application Line control in the decentralized or centralized method.

Parallel link

Function Easily enables data link between FX PLCs.

1.2.3

Application Line control in the decentralized or centralized method.

Computer link

Function

Connects a personal computer or another computer as the master

station, and connects FX PLCs as slave stations.

Protocols in a computer support computer link protocol formats 1 and 4.

1.2.4

Application Data acquisition and centralized control.

Inverter

communication

Function Communicates with and controls Mitsubishi inverter FREQROL.

1.2.5

Application

Operation monitoring, writing of control values, referencing and

changing parameters, etc.

General-purpose serial communication

Reference

subsection

Non-protocol

communication

Function

Receives and sends data from/to various pieces of equipment with an

RS-232C or RS-485 interface in non-protocol procedures.

1.2.6

Application

Data reception and sending from/to a personal computer, bar code

reader, printer and other various measuring instruments.

Sequence program

Reference

subsection

Programming

communication

Function

Adds an RS-232C and an RS-422 port in addition to the provided RS-

422 port in PLCs.

1.2.7

Application

Simultaneously connection of two display units, programming tools,

etc.

Remote

maintenance

Function

Connects with a PLC located in a remote location through a modem

and telephone line to enable program transfer and remote monitoring

access.

1.2.8

Application Maintenance of sequence programs in FX PLCs.

Loading...

Loading...