HEAD OFFICE: TOKYO BUILDING, 2-7-3 MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

HIMEJI WORKS: 840, CHIYODA CHO, HIMEJI, JAPAN

JY997D16901C

(MEE)

Effective Nov.2007

Specifications are subject to change without notice.

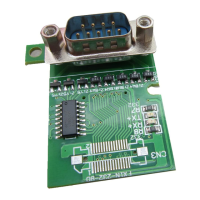

USER'S MANUAL - Data Communication Edition

FX SERIES PROGRAMMABLE CONTROLLERS

MODEL

FX-U-COMMU-E

MODEL CODE

09R715

Loading...

Loading...