Rovema CMK Operator’s Manual

Section 5: Operator Controls

200246 CMK Operators Manual (02/06/2006) 5-19

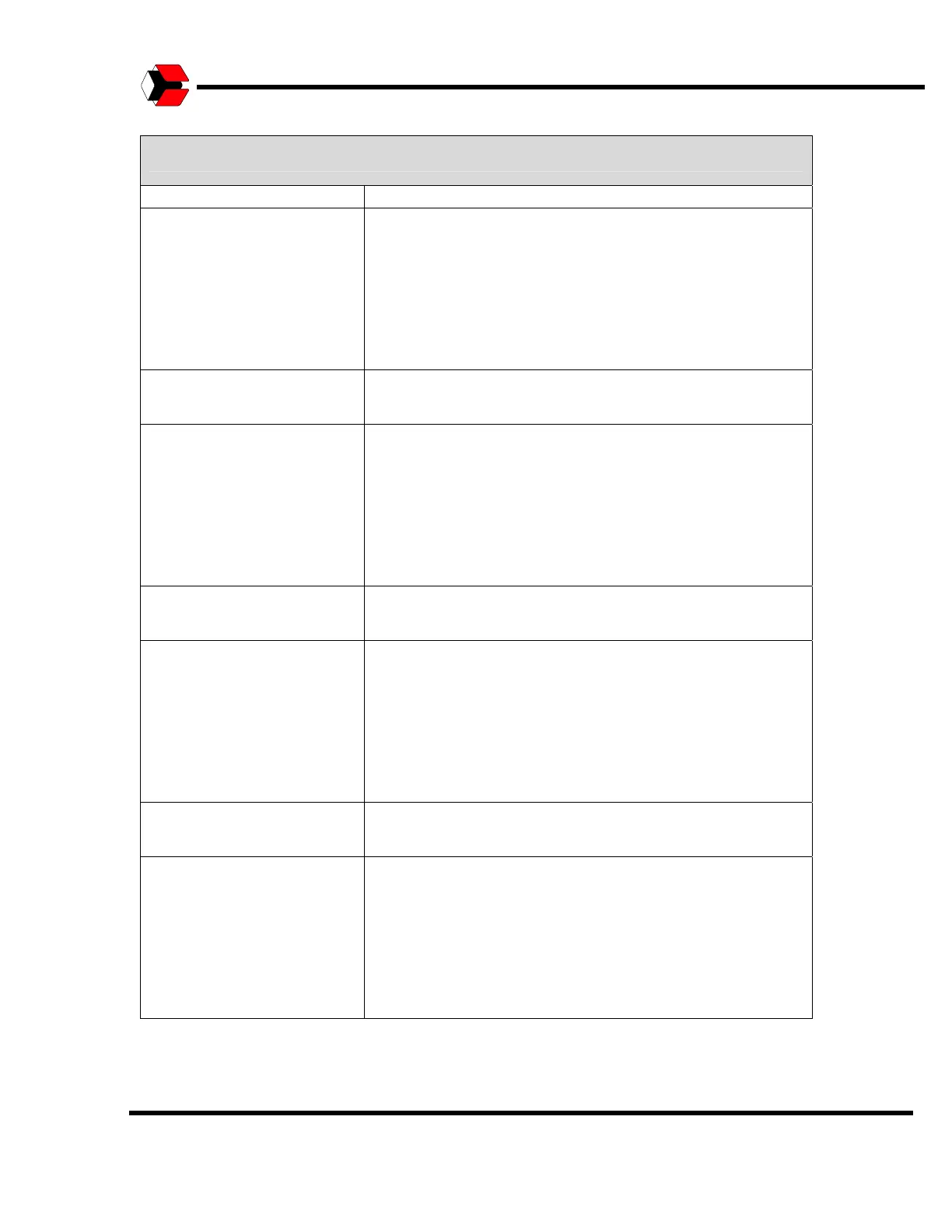

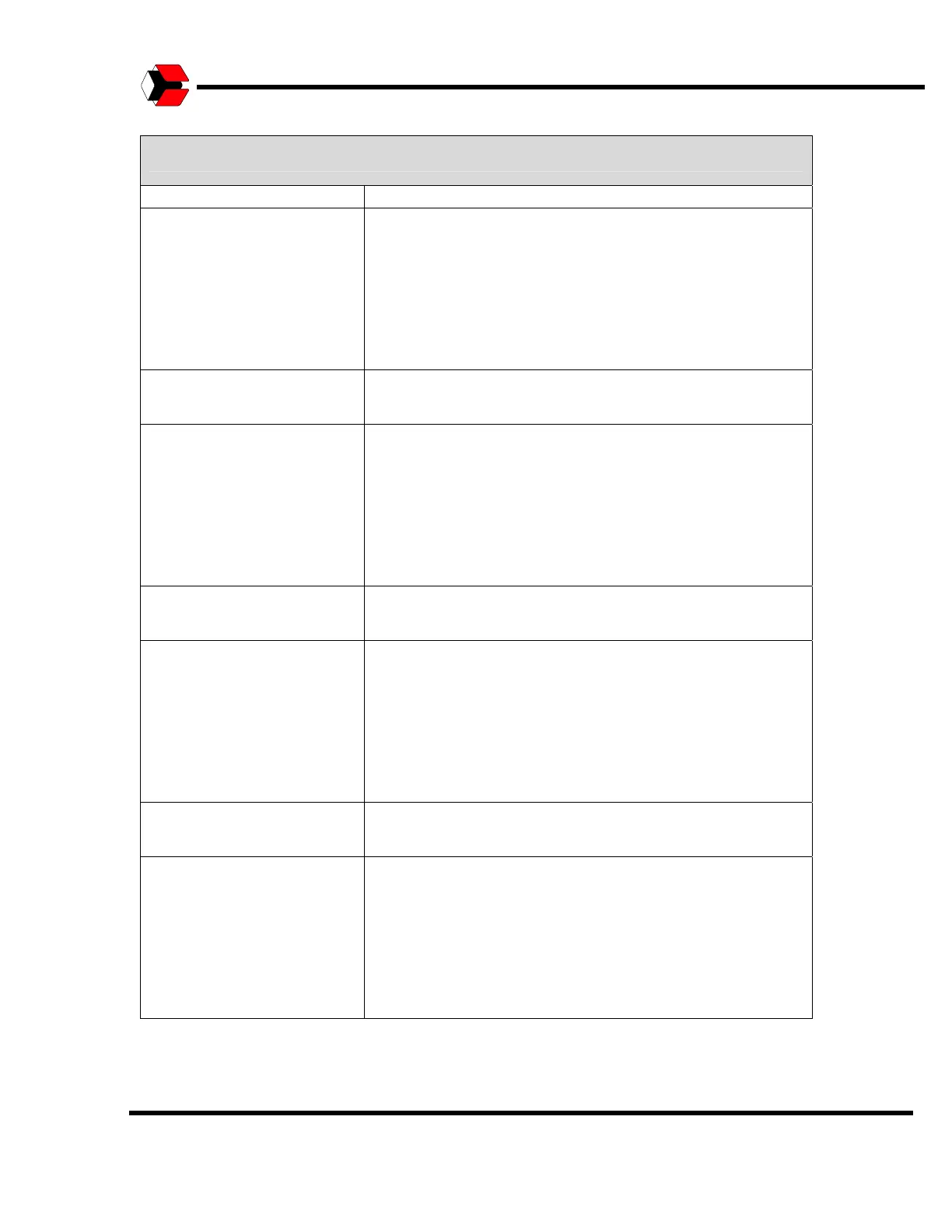

Bag Transfers Parameters - Continued

Parameter Description

Bag Transfer 2 Drop Bucket This is the setting that allows bags from each Bag Transfer to

be dropped into unique buckets on the bucket conveyor.

NOTE: Because of various timing issues the bucket in which

the stack ends up will not necessarily be the same as the

bucket during which drop signal is given. Therefore each Bag

Transfer station will not necessarily have unique Drop Bucket

parameters even when each station is properly dropping

stacks into unique buckets.

Bag Transfer 3 Drop Position This value is used to adjust where the product is dropped in

the bucket. This is used to align the product drops with each

bucket in order to create as neat a stack as possible.

Bag Transfer 3 Drop Bucket This is the setting that allows bags from each Bag Transfer to

be dropped into unique buckets on the bucket conveyor.

NOTE: Because of various timing issues the bucket in which

the stack ends up will not necessarily be the same as the

bucket during which drop signal is given. Therefore each Bag

Transfer station will not necessarily have unique Drop Bucket

parameters even when each station is properly dropping

stacks into unique buckets.

Bag Transfer 4 Drop Position This value is used to adjust where the product is dropped in

the bucket. This is used to align the product drops with each

bucket in order to create as neat a stack as possible.

Bag Transfer 4 Drop Bucket This is the setting that allows bags from each Bag Transfer to

be dropped into unique buckets on the bucket conveyor.

NOTE: Because of various timing issues the bucket in which

the stack ends up will not necessarily be the same as the

bucket during which drop signal is given. Therefore each Bag

Transfer station will not necessarily have unique Drop Bucket

parameters even when each station is properly dropping

stacks into unique buckets.

Bag Transfer 5 Drop Position This value is used to adjust where the product is dropped in

the bucket. This is used to align the product drops with each

bucket in order to create as neat a stack as possible.

Bag Transfer 5 Drop Bucket This is the setting that allows bags from each Bag Transfer to

be dropped into unique buckets on the bucket conveyor.

NOTE: Because of various timing issues the bucket in which

the stack ends up will not necessarily be the same as the

bucket during which drop signal is given. Therefore each Bag

Transfer station will not necessarily have unique Drop Bucket

parameters even when each station is properly dropping

stacks into unique buckets.

Figure 5.24

Bag Transfer Parameter Descriptions - Continued

Loading...

Loading...