10/00

4-162

Phaser 790/DocuColor 2006

ADJ 8.1, ADJ 9.1

Initial Issue

Repairs and Adjustments

Adjustment

1. Calculate the difference between the average measured value and the nominal values as

displayed in the Table 1.

2. Calculate the required adjustment value, allowing 1 unit increment to equal 0.17 mm of

change in top-to-bottom registration, or 0.50 mm of change in side-to-side registration.

3. Prepare to adjust the printer registration.

a. Enter the Diagnostic Mode (IOT) (GP 1).

b. Press the Menu button until IOT PARAM SET is displayed.

c. Press the Item Enter button.

d. Press the Up Arrow or Down Arrow button until CTRL VAL SET is displayed, then

press the Item Enter button.

e. Using the Up Arrow and Down Arrow buttons, select the Menu Number from the

Table 2.

f. Press the Item Enter button to display the current value of that parameter.

g. Using the Up Arrow and Down Arrow buttons, change the value as required.

h. Press the Item Enter button to write the new value.

i. Scroll the menu until DIAG EXIT is displayed, then press the Item Enter button.

j. Wait until the message PLEASE POWER OFF is displayed and then switch off and

switch on the power.

4. Perform the check again.

ADJ 9.1 Developer Spacing

Purpose

The purpose is to ensure that the Developer Housing is at the correct distance from the Copy/

Print Cartridge.

Check

WARNING

To avoid personal injury or shock, do not perform repair activities with the power switch

on or electrical power applied to the machine.

1. Switch off the machine power and disconnect the machine Power Cord.

2. Remove the Top Cover Assembly (REP 14.4).

3. Release the Rotary Latch. Turn the Rotary Frame clockwise until the magnetic roll of the

target Developer Housing is at the top. Continue to turn until the Rotary Latch catches in

the notch of the Rotary Frame.

CAUTION

Do not touch the surface (surface around circumference) of the white tracking roll with your fin-

gers while performing the following step. If you accidentally touch the surface of the tracking

roll with your fingers or if oily substances get on the surface, wipe the roll clean with a clean

cloth.

4. Clean the White Tracking Roll in front of the target Developer Assembly (in front of the

Magnetic Roll) with a clean cloth (Figure 1).

5. Make a mark on the White Tracking Roll, at the edge of the White Seal, in front of the tar-

get Developer Assembly (in front of the Magnetic Roll).

If a mark already exists on the White Tracking Roll, rotate the roll to align the mark with

the edge of the White Seal (Figure 1).

CAUTION

Turn the Rotary Frame as slowly as possible while performing the following step. Turning the

Rotary Frame too fast will produce a discrepancy in the amount of position change, thus mak-

ing it impossible to get an accurate reading. Visually inspect to make sure the black drum

flange and tracking roll touch each other while turning.

If you do not raise the lever of the Rotary Latch in the following step, the lever and tracking roll

will touch. This will allow the tracking roll to turn and you will not be able to accurately deter-

mine the amount of position change.

NOTE: The tracking roll is rotated when the black drum flange and tracking roll touch in the fol-

lowing step of the procedure.

6. Release the Rotary Latch which prevents the Developer Housing from turning. Turn the

Rotary Frame as slowly as possible 360 degrees (clockwise). This will allow you to mea-

sure how much the position has changed by how far the mark has moved from the edge

of the White Seal.

7. Check the Developer Spacing (Figure 1).

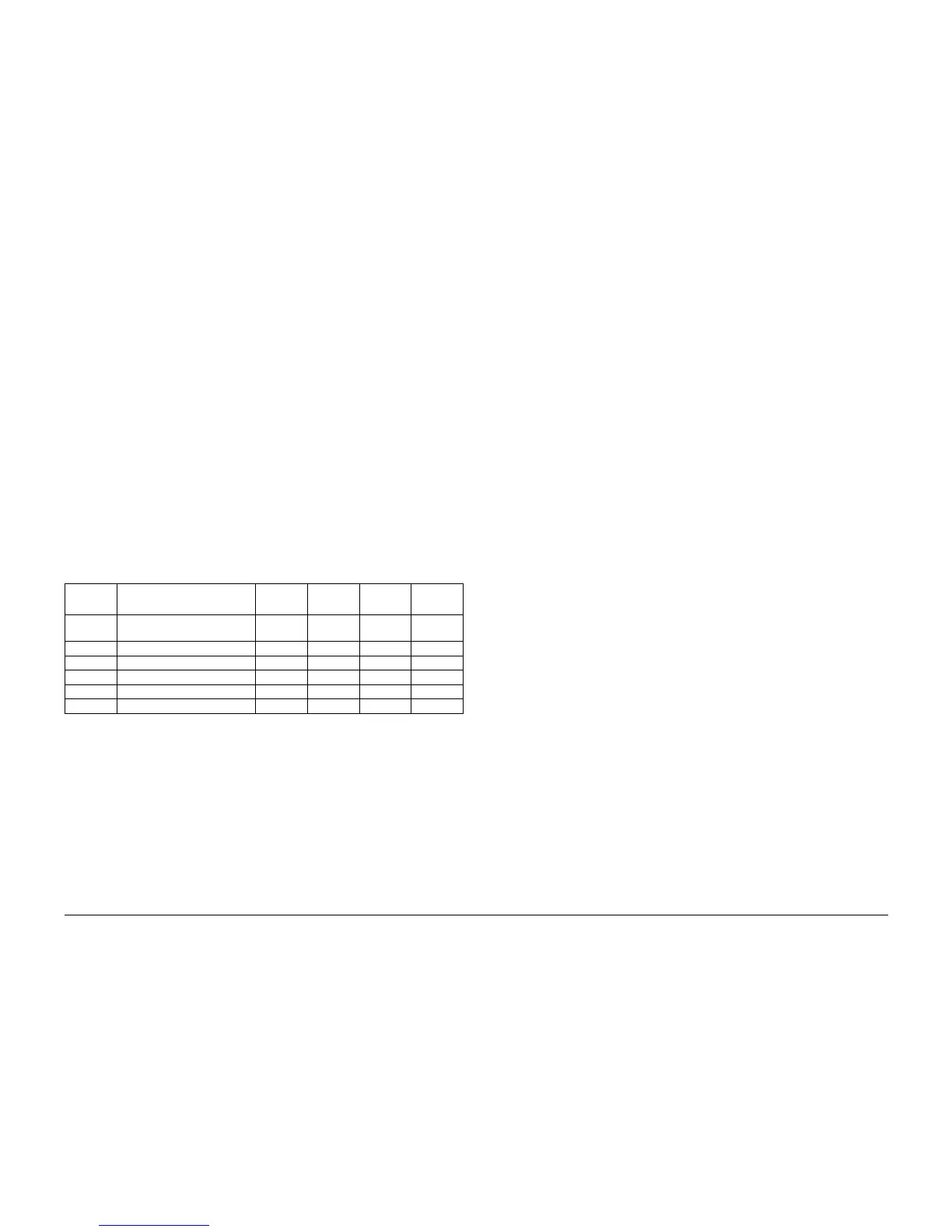

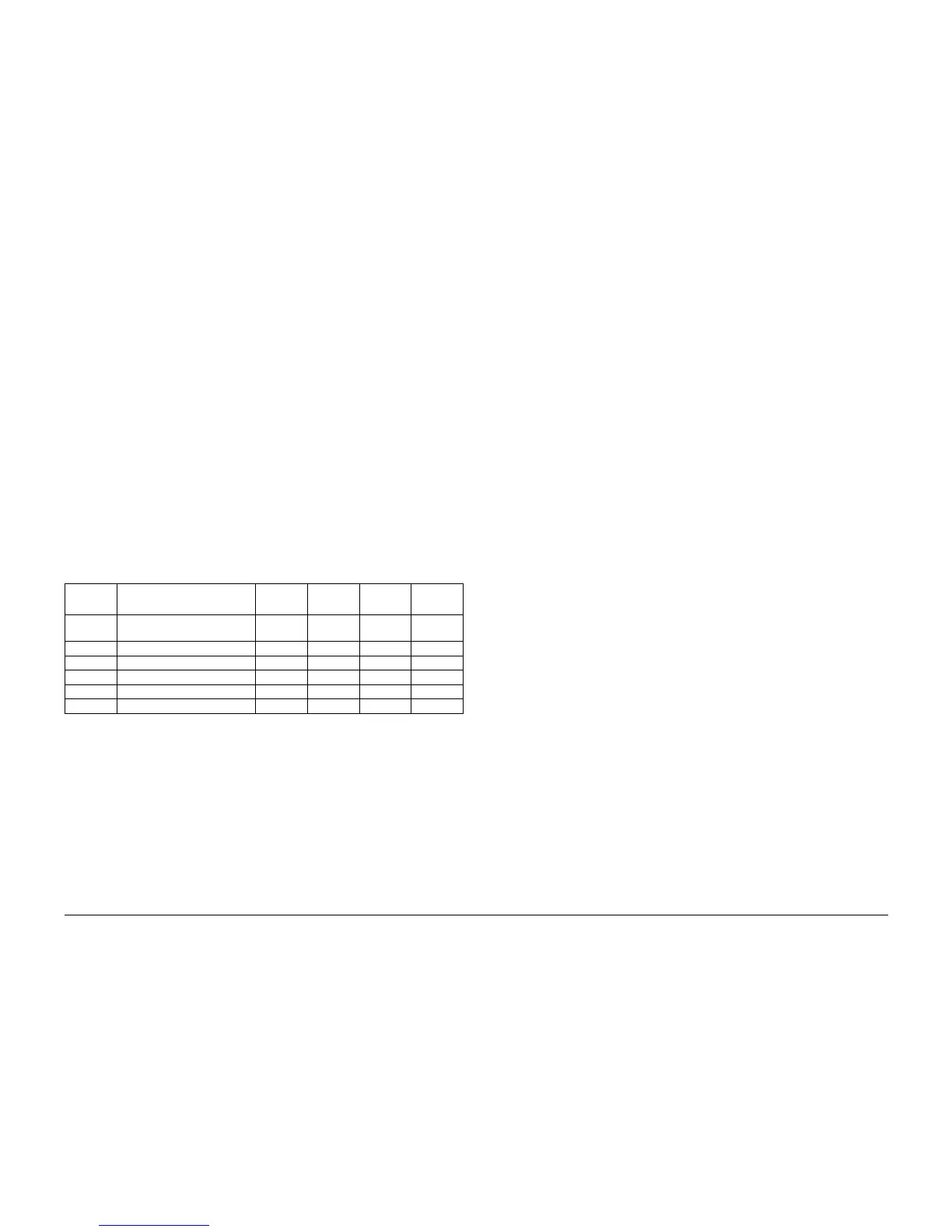

Table 2 Printer Registration Items for the Parameters

Menu No. Function

Default

Value

Maximum

Value

Minimum

Value Unit

11 Side-To-Side Registration 201 128 127 0.10 mm

16 Top-To-Bottom (Tray 1) 30 64 0 0.17 mm

17 Top-To-Bottom (Tray 2) 37 64 0 0.17 mm

18 Top-To-Bottom (Tray 3) 35 64 0 0.17 mm

19 Top-To-Bottom (Bypass Tray) 28 64 0 0.17 mm

1A Top-To-Bottom (Duplex Tray) 17 64 0 0.17 mm

Loading...

Loading...