Electrical Installation

3

3.4 Main Circuit Terminal Block Wiring Procedure

YASKAWA SIEPC71061705H GA700 Series Technical Manual 89

Figure 3.22 Tightening Slotted Screws

• After you connect the wires to the terminal block, lightly pull on the wires to make sure that they do not come

out of the terminals.

• Remove the correct section of the wiring cover to make wiring easier.

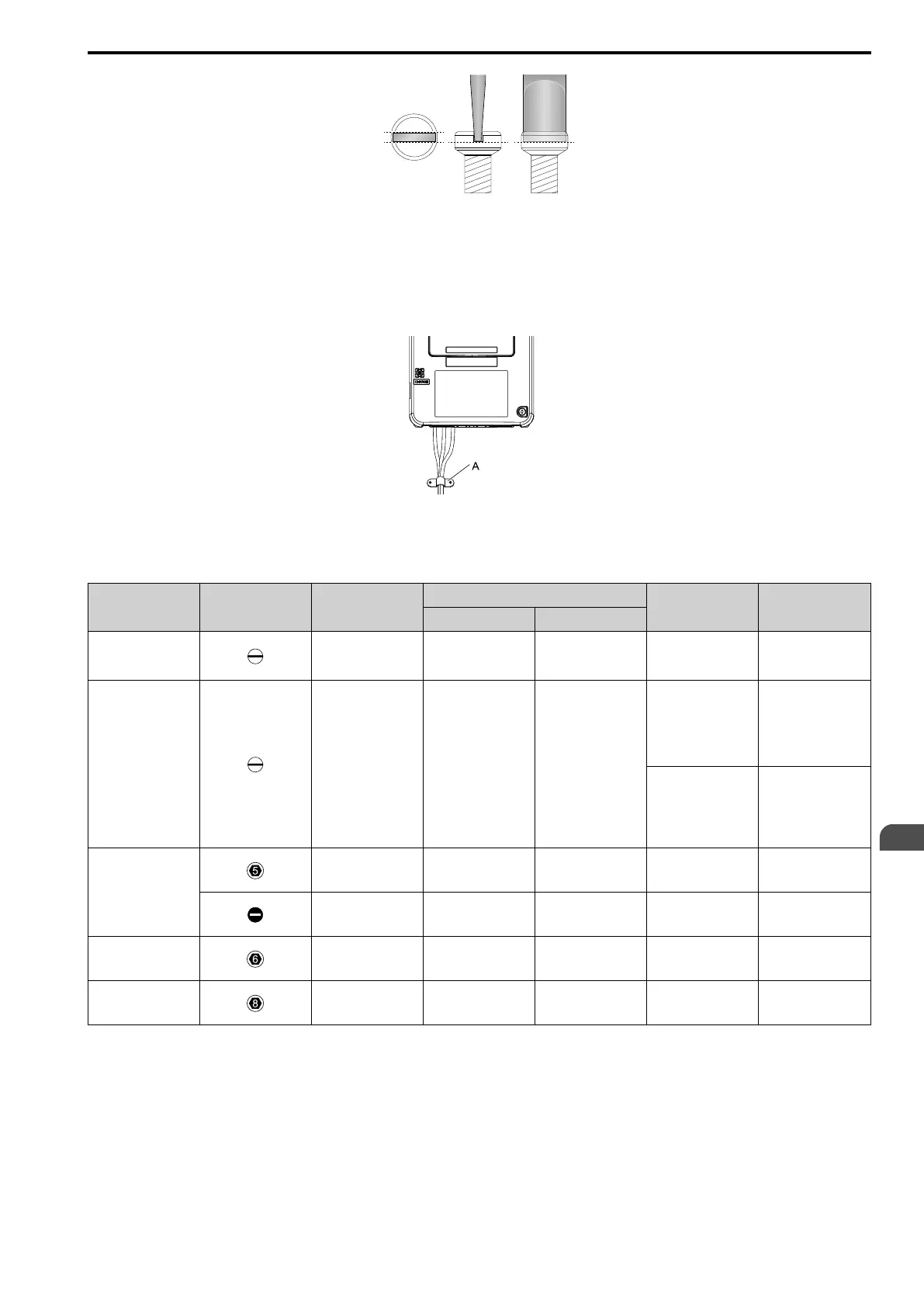

• Do not let strain on the wiring cause damage. Use a strain relief near the wiring to release the tension. Refer to

Figure 3.23 for an example.

A - Cable clamp

Figure 3.23 Strain Relief Example

Table 3.5 Recommended Wiring Tools

Screw Size Screw Shape Adapter

Bit

Torque Driver Model

(Tightening Torque)

Torque Wrench

Model Manufacturer

M4 Bit SF-BIT-SL 1,0X4,0-70 PHOENIX CONTACT

TSD-M 3NM

(1.2 - 3 N∙m

(10.6 - 26.6 lbf∙in))

-

M5

*1

Bit SF-BIT-SL 1,2X6,5-70 PHOENIX CONTACT

Wire Gauge ≤

25 mm

2

(AWG 10):

TSD-M 3NM

(1.2 - 3 N∙m

(10.6 - 26.6 lbf∙in))

Wire Gauge ≤

25 mm

2

(AWG 10): -

Wire Gauge ≥

30 mm

2

(AWG 8): -

Wire Gauge ≥

30 mm

2

(AWG 8):

4.1 - 4.5 N∙m

(36.3 - 39.8 lbf∙in)

*2

*3

M6

Bit SF-BIT-HEX 5-50 PHOENIX CONTACT -

5 - 9 N∙m

(44.3 - 79.9 lbf∙in)

*2

*3

Bit SF-BIT-SL 1,2X6,5-70 PHOENIX CONTACT -

3 - 3.5 N∙m

(26.6 - 31.0 lbf∙in)

*2

*3

M8 Bit SF-BIT-HEX 6-50 PHOENIX CONTACT -

8 - 12 N∙m

(70.8 - 106.2 lbf∙in)

*2

*3

M10 Bit SF-BIT-HEX 8-50 PHOENIX CONTACT -

12 - 14 N∙m

(106.2 - 123.9 lbf∙in)

*2

*3

*1 When wiring drive models 2056, 4089, and smaller, select the correct tools for the wire gauge.

*2 Use 6.35 mm (0.25 in) bit socket holder.

*3 Use a torque wrench that can apply this torque measurement range.

■ Main Circuit Terminal Block Wiring Procedure

Remove the keypad and front cover before wiring the main circuit terminal block.

Loading...

Loading...