5.3Linearsynchronousmotor

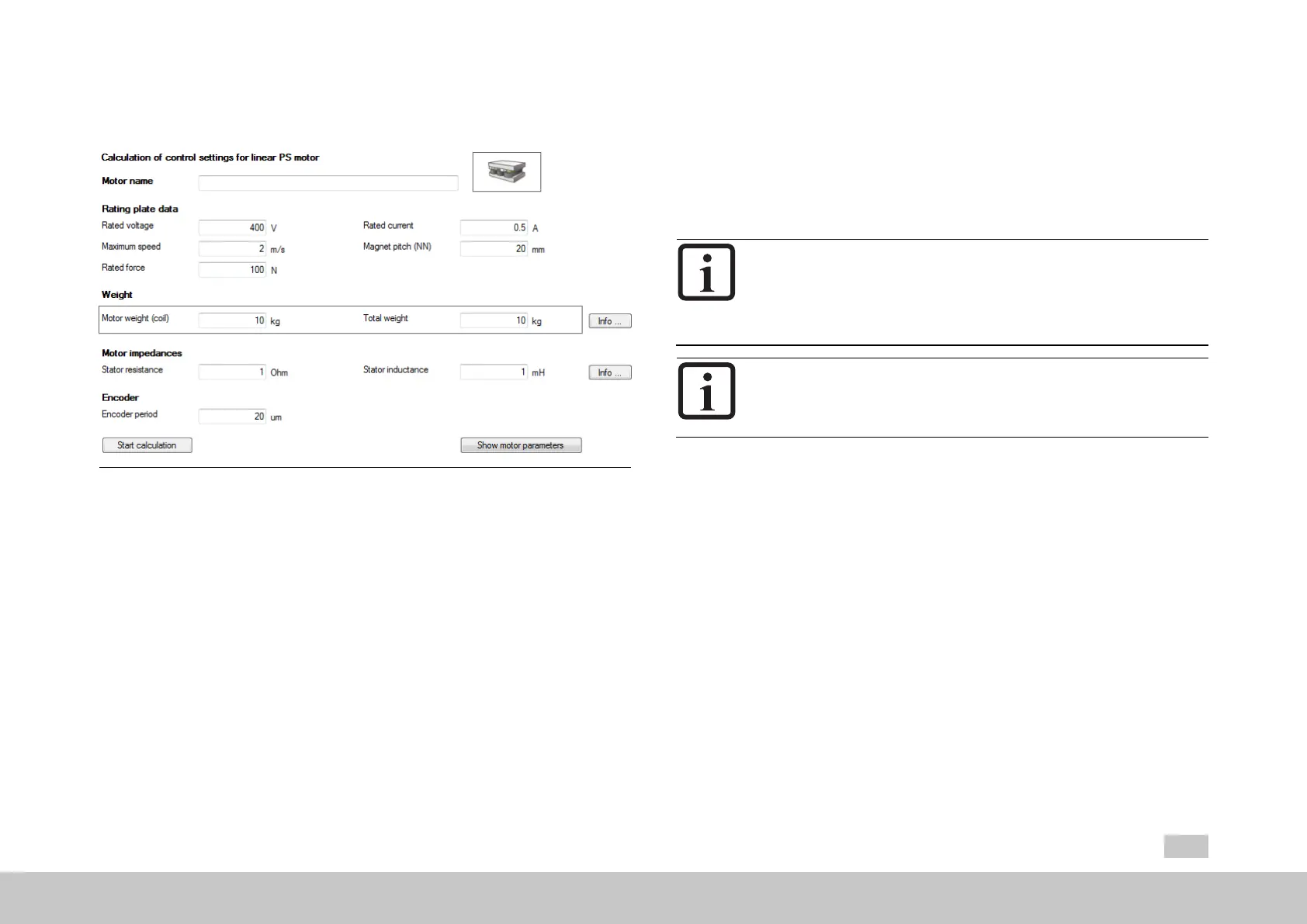

Fig. 5.4: “Linear synchronous motor settings” screen

There are two methods of creating a motor data set for the linear synchronous motor.

Variant1:Motorcalculation

Variant2:Motoridentification(see Section"Motoridentification"onpage 43)

Variant 1: Motor calculation

Entermotordata

Themotordatarelevanttothecalculationmustbeenteredfromthedata

sheet.

Clickon“Startcalculation”.

MOOG

ID

No.: CB40859-001 Date: 02/2018

MSD Servo Drive- Device Help

35

5 Motor

IfthemomentofinertiaofthemotorP 461 - Mot_Jisnotknown,avalue

roughlycorrespondingtothemotor'smomentofinertiamustbeapplied.

The calculation process can be monitored in theMoogDRIVEADMINISTRATOR

via the menu,View, Messages.

Calculationofoperatingpoint:FluxP 462 - MOT_FLUXNom

Calculationof:current,speedandpositioncontrolparameters

NOTE

P 490 - MOT_ISLinRot =LIN(1):Theparameterwillautomatically

setthenumberofmotorpolepairstoP 463 - Mot_PolePairs =1.

Asaresult,aNorthtoNorthpolepitchcorrespondstoonevirtual

revolution(P 49 - Mot_MagnetPitch).

NOTE

Allexistingmotorparametersareoverwritten.

Calculated values

Translationofthelinearnominalquantitiesintovirtualrotarynominal

quantities

Defaultvaluesforautocommutation

Encoderlinespervirtualrevolution

Fluxsettings(includingfortorqueconstant)

ControlsettingsforPIcurrentcontroller:Thecurrentcontrolleris

dimensionedbasedontheactual switchingfrequencyset.

PIspeedcontrollerandpositioncontrollergain:A moderately rigid

mechanism and moment of inertia matching from load to motor with a ratio

of 1:1 is assumed here.

Thedefaultvalueforspeedtrackingerrormonitoringcorrespondsto50%of

the nominal speed.

V/Fcharacteristic

Loading...

Loading...