6.12Multi-turnencoderasasingle-turn

encoder

By way of parameters P548[0] - ENC_CH1_MTEnable = 1 (for Channel 1) and

P585[0] - ENC_CH3_MTEnable = 1 (for Channel 3) a multi-turn encoder can be run

as a single-turn encoder. This function is used primarily for testing purposes.

MOOG

ID

No.: CB40859-001 Date: 02/2018

MSD Servo Drive- Device Help

101

6 Encoder

6.13Distance-codedreferencemarks

In the case of encoders with distance-coded reference marks, multiple reference

marks are distributed evenly across the entire travel distance. The absolute position

information, relative to a specific zero point of the measuring system, is determined

by counting the individual increments (measuring steps) between two reference

marks. The absolute position of the scale defined by the reference mark is assigned

to precisely one measuring step. Before an absolute reference can be created or the

last selected reference point found, the reference mark must be passed over. In the

worst-case scenario this requires a rotation of up to 360°. To determine the

reference position over the shortest possible distance, encoders with increment-

coded reference marks are supported (e.g. HEIDENHAIN ROD 280C).

The reference mark track contains multiple reference marks with defined increment

differences. The tracking electronics determines the absolute reference when two

adjacent reference marks are passed over after just a few degrees of rotation.

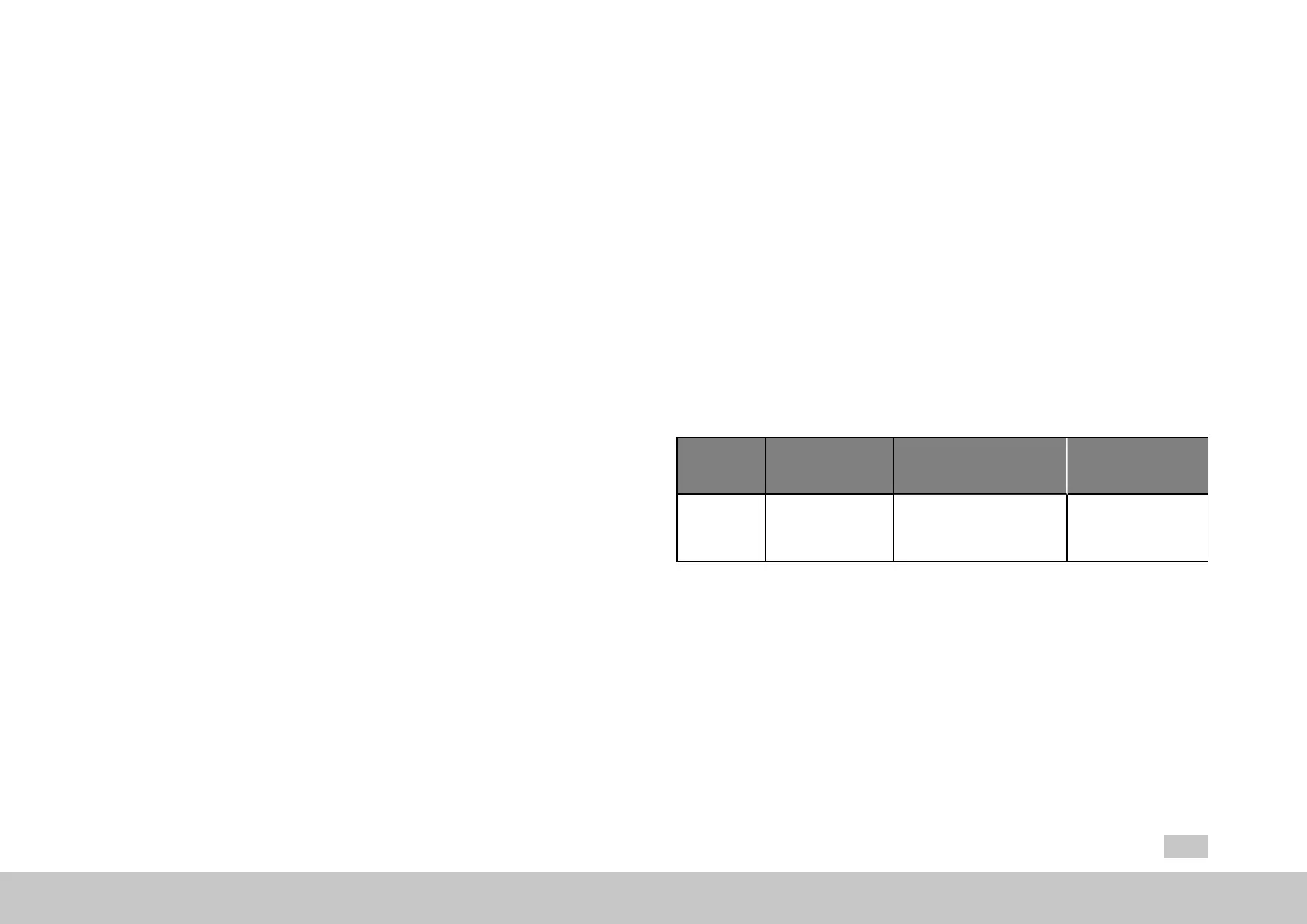

Number of

pulses (P

542)

Number of ref-

erence marks

Basic increment G Nom-

inal Increment A (P 610)

Basic increment G

Nominal increment

B (P 611)

18 x 1000

lines

18 basic marks

+ 18 coded

marks = Σ 36

Reference measure A =

1000 lines

corresponding to 20°

Reference

measure B =

1001 lines

Table 6.37: Example of a rotary system on encoder channel Ch1

Loading...

Loading...