6.10Axiscorrection

The position value delivered by the encoder system and the actual position value on

the axis may vary for a number of reasons. Such non-linear inaccuracies can be

compensated by axis error correction (using position- and direction-dependent

correction values). For this, a correction value table is filled with values for each of

the two directions. The respective correction value is produced from the current axis

position and the direction of movement by means of cubic, jerk-stabilized

interpolation. The position value is adapted on the basis of the corrected table. Both

tables contain 250 interpolation points.

The correction range is within the value range delimited by parameters P591-

ENC_ACOR_PosStart "Start position" and P592-ENC_ACOR_PosEnd "End

position correction". The start position is preset on the user side; the end position is

determined on the drive side.

Possible cause of deviations

Inaccuracyofthemeasuringsystem

Slackinmechanicalelementssuchasthegearing,coupling,feedspindle

etc.

Thermalexpansionofmachinecomponents.

MOOG

ID

No.: CB40859-001 Date: 02/2018

MSD Servo Drive- Device Help

97

6 Encoder

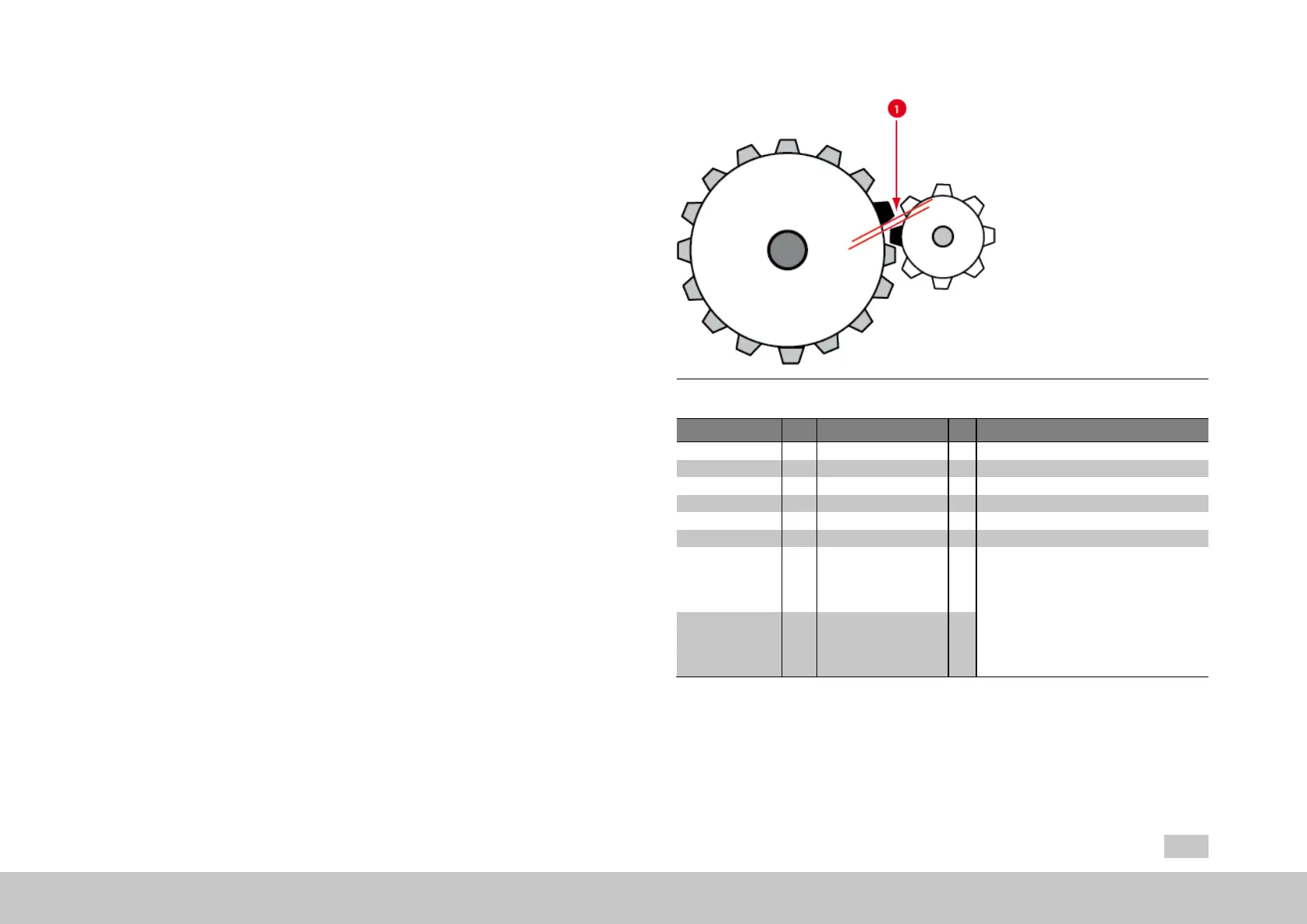

Fig. 6.11: Mechanical system axis correction (① = slack in gearing)

P No. Index Name / Setting Unit Description

530 0 ENC_Encoder1Sel Channelselectionforthe1stEncoder

531 0 ENC_Encoder2Sel Channelselectionforthe2ndEncoder

590 0 ENC_ACOR_Sel

0(=OFF) Noencoderselected

1(=1stEncoder) 1.encoderselected

2(=2ndEncoder) 2.encoderselected

591 0 ENC_ACOR_PosStart Definitionofcorrectionrange:Therangeis

definedbyparametersP 0591 ENC_ACOR_

PosStartStartpositionand

P 0592 ENC_ACOR_PosEndendposition.

Thestartpositionisuser-specified;theend

positionisdeterminedonthedevicesidefrom

themaximumvalueofcorrectiontable

interpolationpointsusedandtheinterpolation

pointpitch

592 0 ENC_ACOR_PosEnd

Table 6.34: Axis correction parameters

Loading...

Loading...