Loading a motor data set

Motordataandcontrolsettingsdialogbox

Selectdataset

Enterencodersettings

Savedata

Commissioning a third-party motor

In the case of third-party motors, basic suitability for operation with servo drives from

Moog must first be verified on the basis of the motor data and the data of any

installed encoder. The values of the parameters for adaptation of the servo drive

must be determined specifically for each motor by calculation or identification. The

two methods differ in that when the motor data set is calculated, the impedances

must be taken from the data sheet. In identification the impedances are measured

automatically. Each motor can only be operated if its field model and the control

parameters are correctly set.

You can obtain the data sets for all standard synchronous motors. On transfer of a

standard motor data set the motor name, electrical data and motion mode are

loaded. Preset parameters are overwritten. The motor data must then be saved in

the device. The motor parameters specified by the manufacturer ensure that a motor

can be subjected to load according to its operational characteristic, provided the

corresponding power is supplied by the drive.

NOTE

Eachmotorcanonlybeoperatedifitsfieldmodelandthecontrol

parametersarecorrectlyset.

MOOG

ID

No.: CB40859-001 Date: 02/2018

MSD Servo Drive- Device Help

32

5 Motor

5.2Synchronousmotor

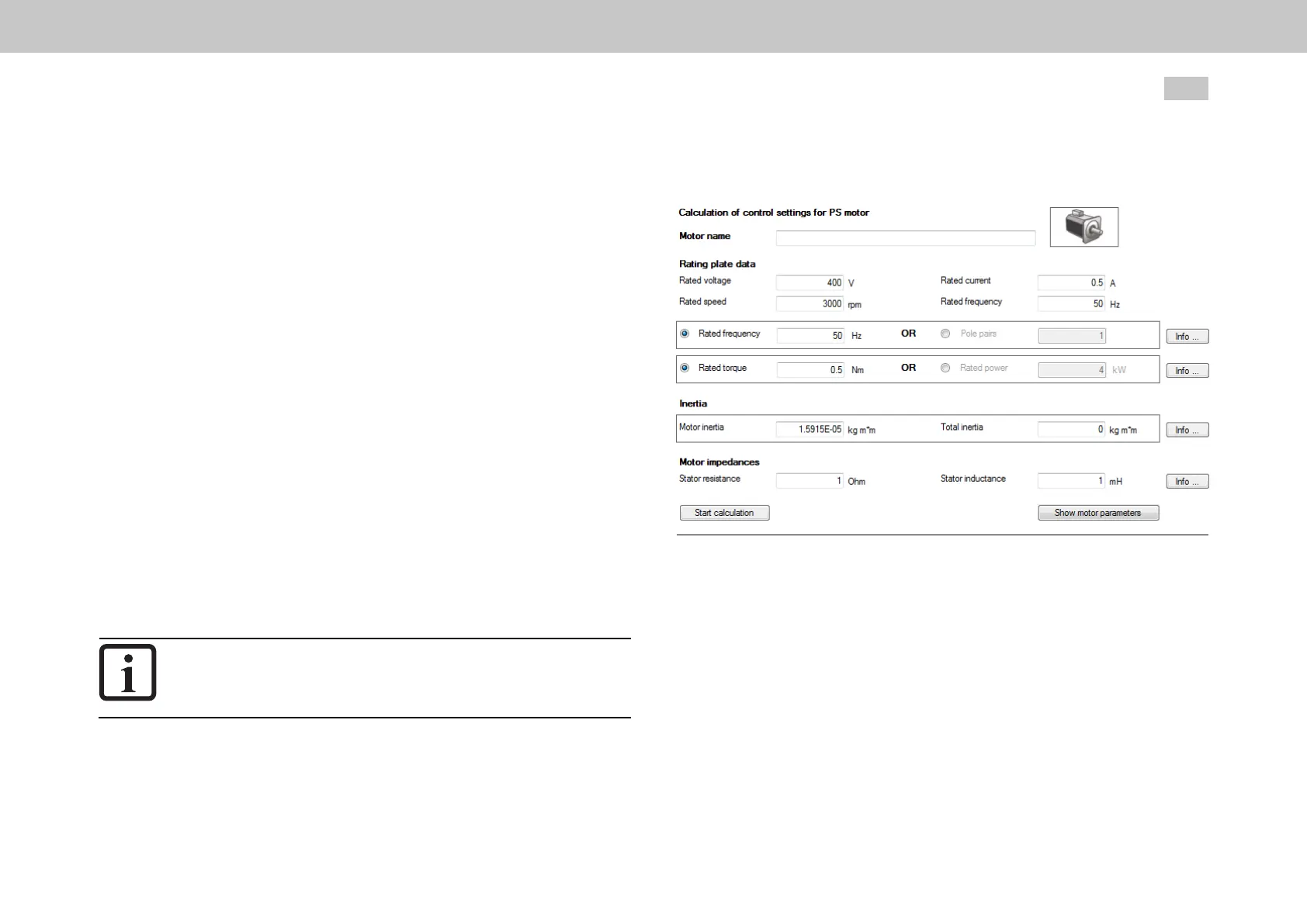

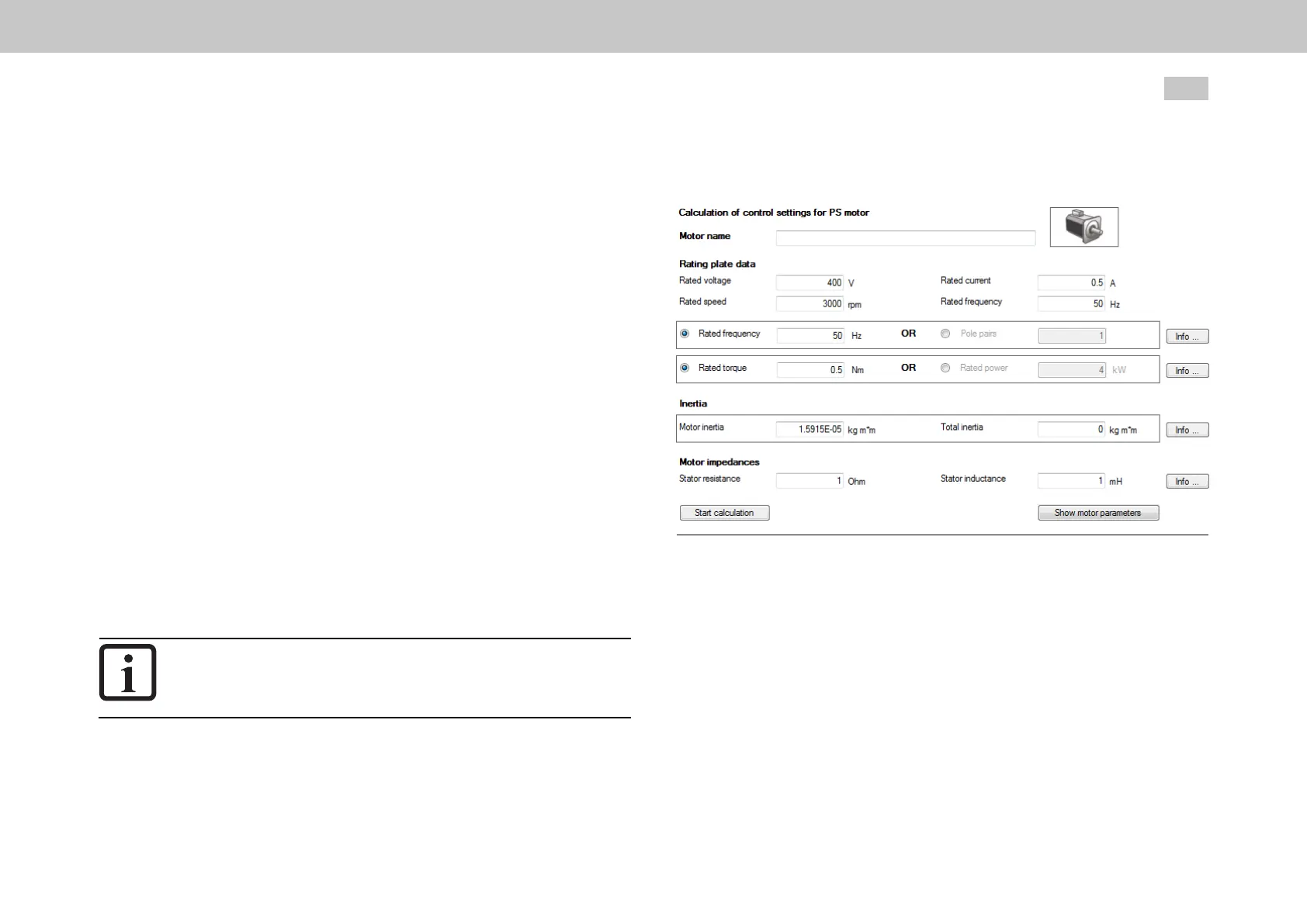

Fig. 5.2: “Synchronous motor configuration” screen

There are two methods of creating a motor data set for the rotary synchronous motor.

Variant1:Motorcalculation

Variant2:Motoridentification(see Section"Motoridentification"onpage

43)

Loading...

Loading...