SSI encoder basics and requirements

The SSI interface on the MSD Servo Drive has been designed as an actual motor

feedback interface. Accordingly, the connected SSI encoder must meet the following

criteria:

Clockanddatainactivelevel=HIGH

Thecurrentpositionmustbeinternallystoredatthefirstfallingclockedge

Nolengthenedcalculationtime(infirstcycle)

Withthefirstrisingclockedge,theencodermustshiftthedatatothefirst

positionbittobetransmitted(MSB)

1Mbpsrate

Datacoding=BinaryorGray

Readingdataafterthedatabitsendispermissible

125µscycle(i.e.internalpositionrefreshrate≪125µs)

Monofloptime≥6µs

Datalinesdrivenwithlogic0duringmonofloptime

Noparitybit

Noerrorbitsorotherstatusbits

≤14MultiTurnbits

MOOG

ID

No.: CB40859-001 Date: 02/2018

MSD Servo Drive- Device Help

67

6 Encoder

SSI wire break monitoring (bit monitoring during monoflop time)

If monitoring is enabled, the drive, as the SSI clock master, will read data for one

more clock cycle after the data bits (reading data after the data bits end is

permissible). The bit that the master reads in addition to the data bits this way comes

from the SSI encoder’s monoflop time. At the time corresponding to this bit, the SSI

encoder must drive the data lines with a logic 0. If the data lines on connector X7 are

open, a logic 1 will be read here. The bit monitoring at this point makes it possible to

determine whether the SSI data lines are being actively driven with a logic 0 at this

point (no “wire break”) or are not (“wire break”). SSI wire break monitoring can be

disabled by setting P546[0] - ENC_CH1_Modeto0001h.

Mode parameters and CycleCount parameters

P546[0] - ENC_CH1_Mode can be used to run a parity evaluation after the data. In

addition, ENC_CH1_Mode makes it possible to run special SSI encoders that deliver

one or more special bits after the data. In this case, the MSD Servo Drive will not

evaluate these bits – this mode is meant to make it possible to work with SSI

encoders that require for these bits to be sampled. P616[0] - ENC_CH1_

CycleCount makes it possible to run slower SSI encoders that cannot handle the

required cycle of 125µs. The control characteristics will deteriorate when using this

type of SSI encoder, and for that reason it is

not

recommended.

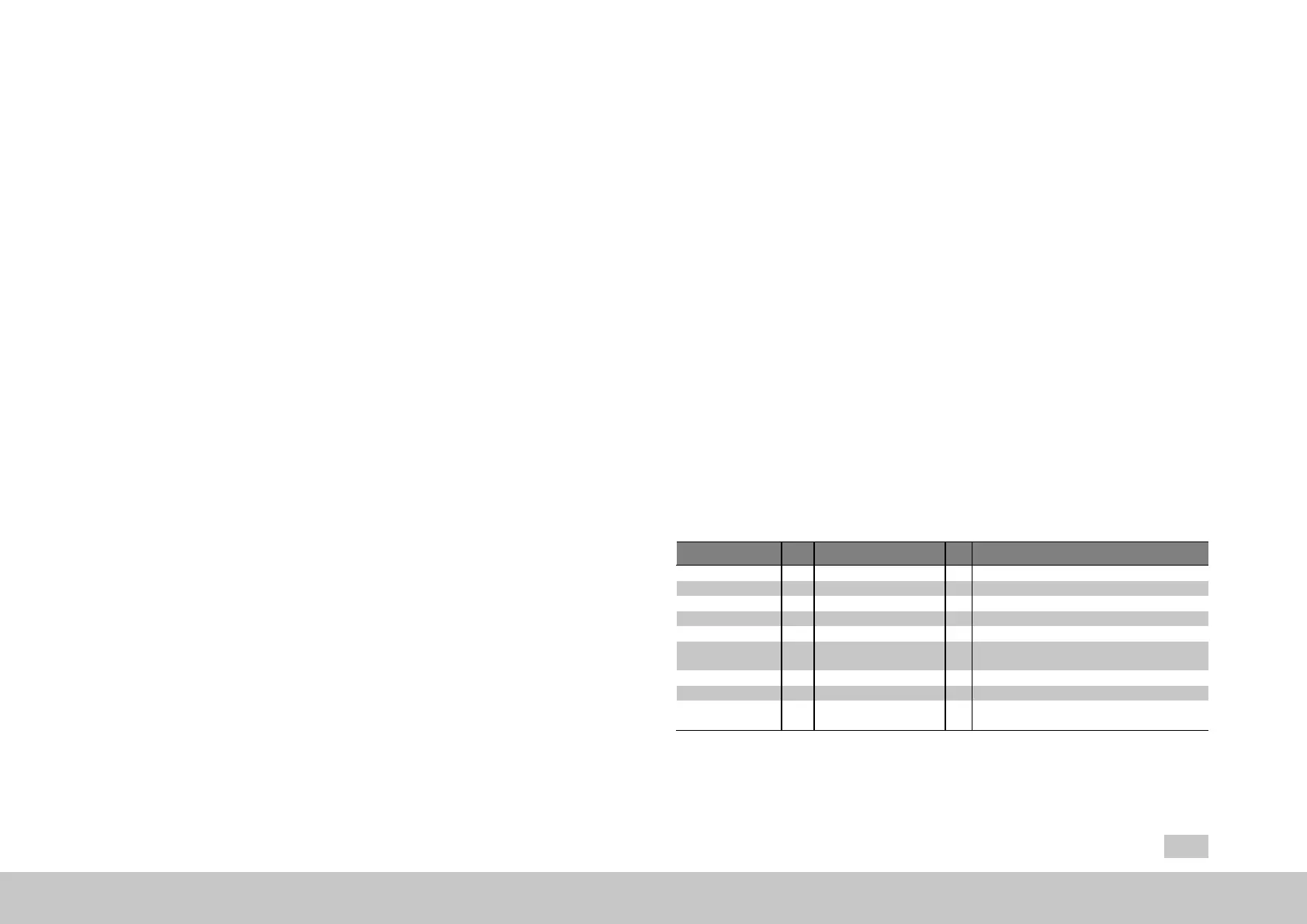

ID Index Name Unit Description

505 0 ENC_CH1_Sel=2 =SSI(2)

543 0 ENC_CH1_MultiT NumberofMultiTurnbits(absoluteencoder)

544 0 ENC_CH1_SingleT NumberofSingleTurnbits(absoluteencoder)

545 0 ENC_CH1_Code Codeselection(SSIabsoluteencoder)

546 0 ENC_CH1_Mode Modeselection(SSIabsoluteencoder)

547 0 ENC_CH1_MTBase MinimumMultiTurnposition(SSIabsolute

encoder)

548 0 ENC_CH1_MTEnable Channel1:Multi-turnassingle-turn

598 0 ENC_CH1_Position inc Positionencoderchannel1

616 0 ENC_CH1_CycleCount Channel1:Positionencodersamplingcycle(nx

125µsec)

Table 6.12: Encoder configuration channel 1 (X7) - SSI parameters

Loading...

Loading...