MOOG

ID

No.: CB40859-001 Date: 02/2018

MSD Servo Drive- Device Help

120

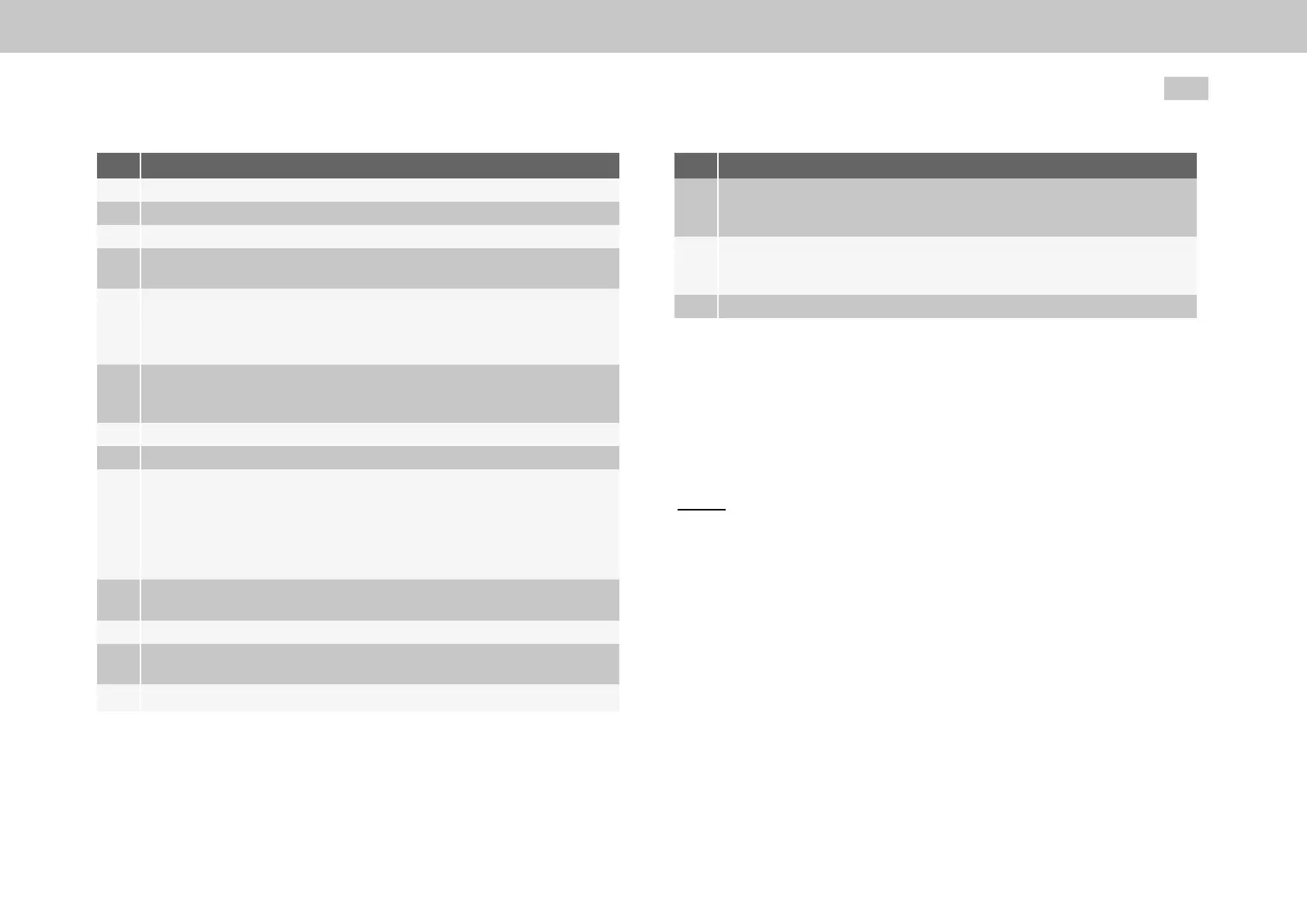

7 Control

No. Action

1 Openmanualmodewindow.

2 Approachstartposition

3 Speedcontrolmodecontrolsetting(sethighrigidity,forsmoothrunning)

4

Settheteachingdirectionifnecessary:P 445[0] - CON_TAB_TeachDir

Default:POS(1)=teachingroutineinpositivedirection.

5

Settheoffsetanddeltaifnecessaryusing:

P 442[0] - CON_TAB_PosStart,default0

P 443[0] - CON_TAB_PosDelta,default1000inc/TabElement

=e.g.(endposinc-startposinc)/4000elements

6

Settheinputtuningifnecessaryusing:

P 447[0] - CON_TAB_Tune.TimeDelay,default0

P 447[1] - CON_TAB_Tune.PosShift,default0

7 Startcontrol

8 Runmotoratlowspeed(≤1rpm).

9

Setthepositionsourcefortheteaching,activateteaching:Select

P 385[0] - CON_TCoggTeachCon= (5)TeachUserRefPosorselect

P 385[0] - CON_TCoggTeachCon= (7)TeachPosEncPconorselect

P 385[0] - CON_TCoggTeachCon= (9)TeachPconActPosorselect

P 385[0] - CON_TCoggTeachCon= (10)TeachPosEncRed.

Theteachingroutinebegins(butonlywithPosStart).

10

Waituntilatleast1motorrevolutioniscompletedintheteachingroutine

(internalfiltertime).

--- CheckP 440[0] - CON_TAB_TabIndexandP 446[0] - CON_TAB_OutVal

11

Withthecontrolstilloperating,theteachingisthenstoppedbycallingthe

calculationfunctiononce:

12

Stop control

No. Action

13

P 385[0] - CON_TCoggTeachCon = (3)CALC1.

Thisimportsallvaluesintotheinternalcompensationtable(bigtablewith

4000elements).

14

Savedevicedata.

-Thepositionsourceusedbytheteachingisalsosavedhere.Itwilllater

beusedforthecompensationonceagaininexactlythesamemanner.

15 UsethescopetomonitorIsqRef_Comp

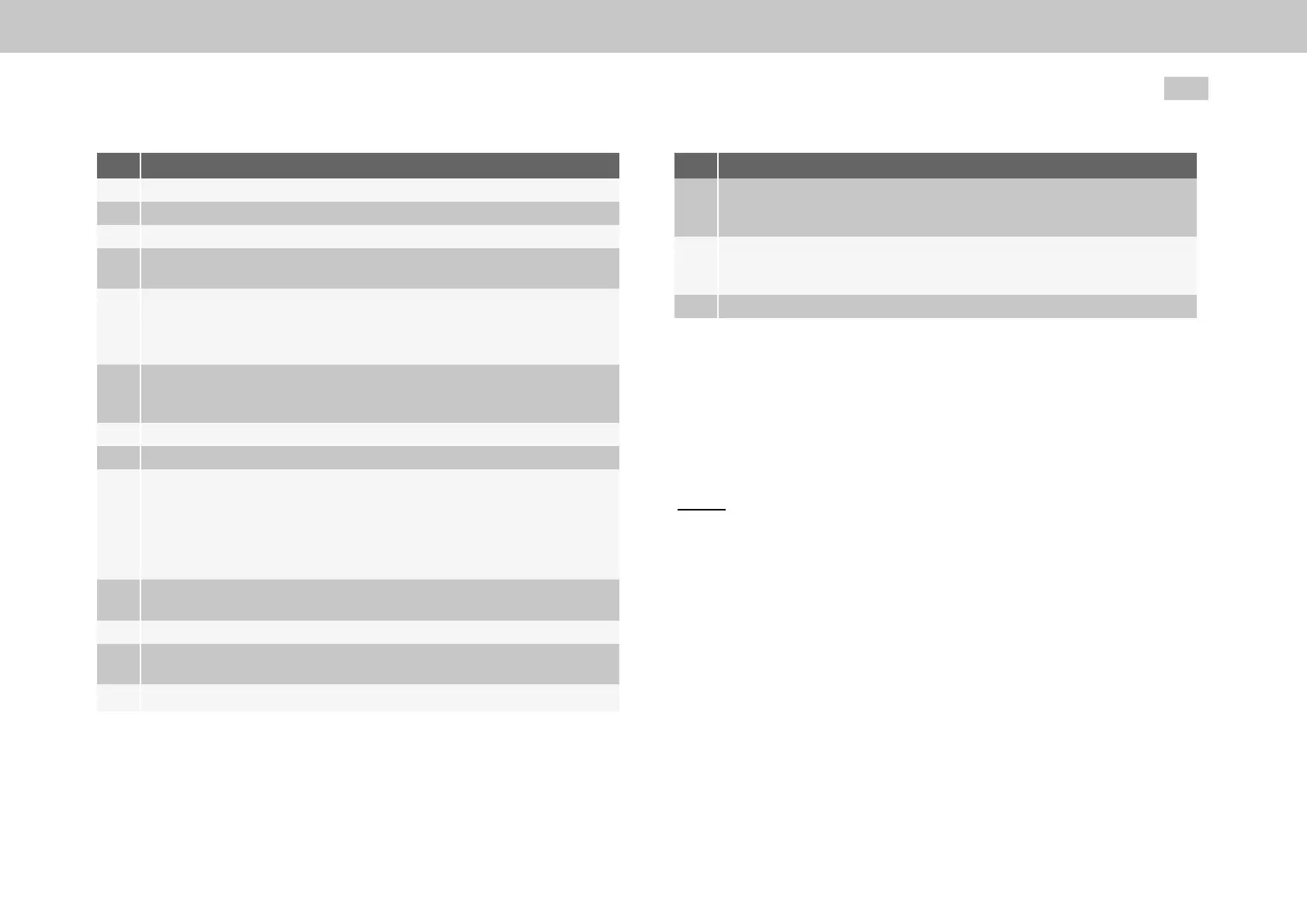

7.3.4.6Compensationasafunctionofmechanicalrotation

(EPMS)

Teaching routine and compensation big CompTab (4000)

- Incremental, ‘rotary' recurring position

- Without offset and delta, with tuning, with fader

- (6) Teach epsm mechanical angle (shaft), SingleTurn position from encoder for

commutation

- (11) Teach singleturn position from position control, SingleTurn position of the

position control, + Homing + axis correction

- (12) Teach epsrs, commutation angle (electrical)

Loading...

Loading...