MOOG

ID

No.: CB40859-001 Date: 02/2018

MSD Servo Drive- Device Help

124

7 Control

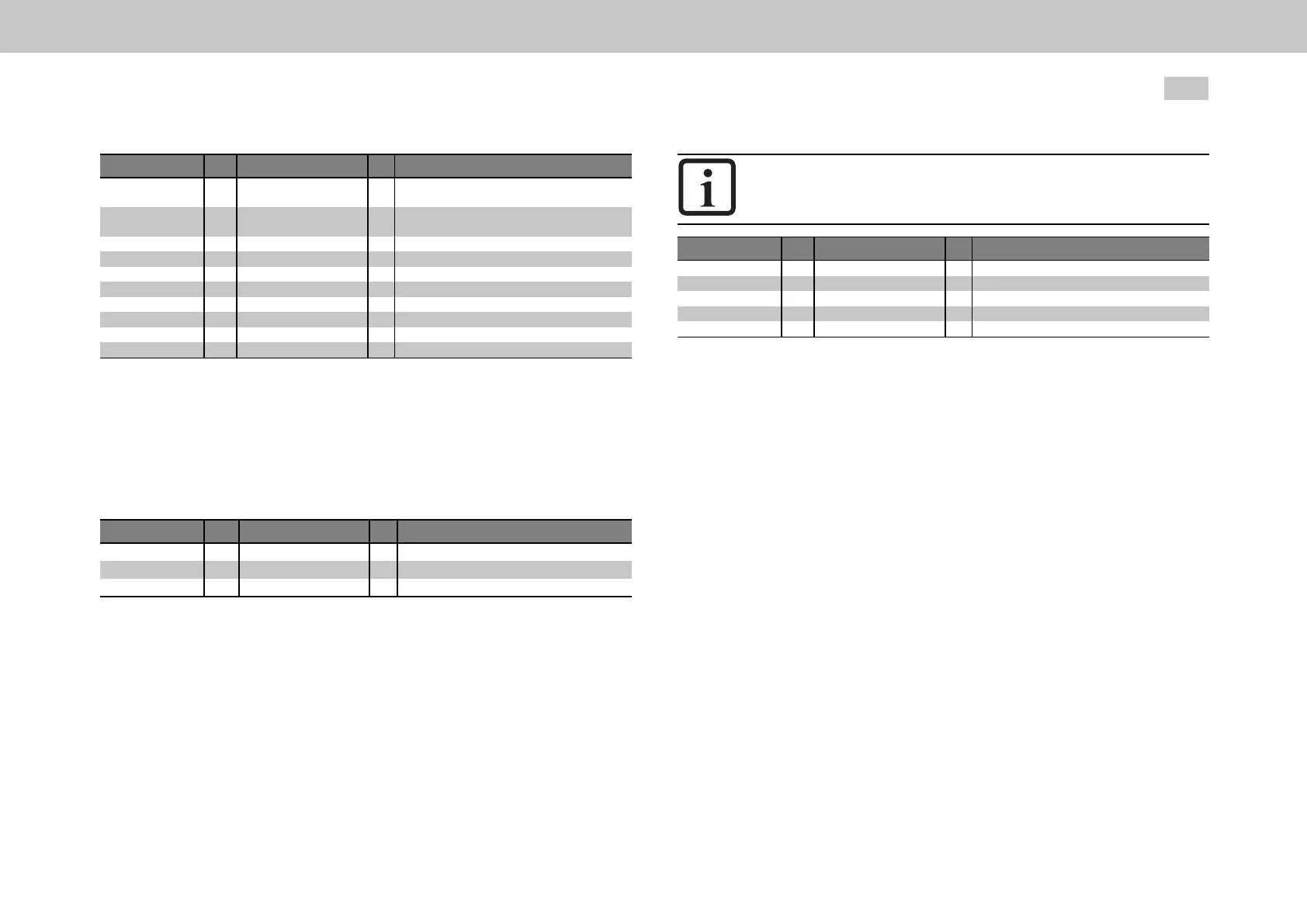

ID Index Name Unit Description

471 0 MOT_Lsig mH

472 MOT_LsigDiff

472 0 Lsig_q@I0 %

Motorleakageinductance(ASM)/stator

inductance(PSM)

q-axisstatorinductancevariation(relativeto

MOT_Lsig)

Inductance@CurrentI0

472 1 Lsig_q@I1 %

472 2 Lsig_q@I2 %

472 3 Lsig_q@I3 %

Inductance@CurrentI1

Inductance@CurrentI2

Inductance@CurrentI3

472 4 CurrentI0 %

472 5 CurrentI1 %

472 6 CurrentI2 %

472 7 CurrentI3 %

CurrentI0relativetoMOT_CNom

CurrentI1relativetoMOT_CNom

CurrentI2relativetoMOT_CNom

CurrentI3relativetoMOT_CNom

Table 7.5: “Advanced torque control - Saturation characteristic” parameters

7.3.5.1.2K-Tcharacteristic

In the overload range the output-side torque is reduced due to rising losses

(iron/copper losses). This behaviour can be compensated by P479[0] - MOT_

TorqueSat.

P No. Index Parameter name Unit Function

479 MOT_TorqueSat

0to4 Nm

5to9 A

Motortorqueasafunctionofthecurrent

Torque;interpolationpoints0to4.

Current;interpolationpoints5to9.

Table 7.6: “K-T characteristic” parameters

7.3.5.2Observer

The speed controller must track a variable moment of inertia in order to adapt the

Servo controller to the machine mechanism (adaptive process). The challenge lies

in precise definition of the moment of inertia, in particular under the influence of

friction, load and other non-modellable disturbances. To nevertheless optimize the

adaptation to the machine mechanism, a technique based on a state observer is

available.

NOTE

PleasecontactMoogbeforeconfiguringtheobserver.

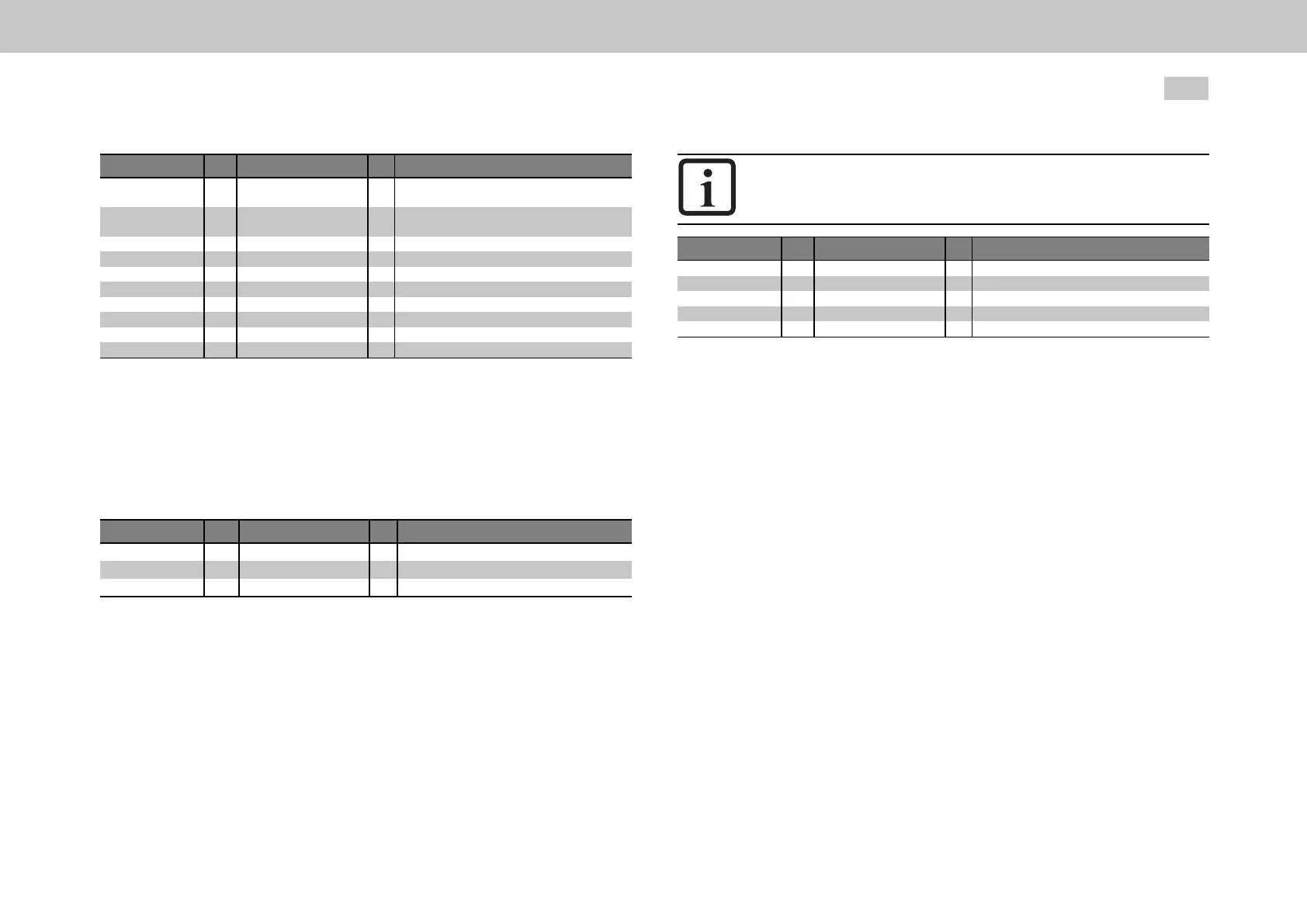

ID Index Name Unit Description

433 0

434

434 0 ms

434 1 1/s

434 2

CON_CCON_ObsMode

CON_CCON_ObsPara

TF

Kp

Tn ms

Selectcurrentobservermode

Currentobserverparameters

Observertimeconstant

Proportionalfeedbackgain

Integralfeedbacktimeconstant

Table 7.7: “Advanced torque control - Observer” parameters

7.3.5.3Overmodulation

The "usqref" and "usdref" components permit so-called overmodulation of the DC

link voltage (limitation to hexagon instead of circle). The maximum output voltage

which can be set for each phase angle results from the circle which fits in the voltage

hexagon (see diagram Section "“Circle and hexagon voltages” diagram" on page

125).

By setting the hexagon modulation "HEX_PHASE(3)", the length of the vector for the

output voltage can be placed in the area of the DC link voltage (red). As a result only

two of the three half-bridges are switched in each switching interval. The third

remains at the upper or lower potential of the DC link voltage for a period of 60° of

the output frequency.

This method has only two thirds of the switching losses of modulation with all three

phases. Disadvantages are higher harmonics of the motor currents and thus less

smooth running at high motor speeds.

Representation of the eight vectors of the three-phase voltage system (3 half-bridges

each with 2 states [2

3

]). The vectors correspond to the DC link voltage U

ZK

and form

a voltage hexagon.

Loading...

Loading...