CAUTION! Damage to the device as a result of incorrect operation!

Failure to exercise caution or follow proper working

procedures may result in damage to the device.

Themotorcanmovesuddenlyduringtheauto

commutation.Themechanismcoupledmustbe

designedforthismovement.

Ifthecommutationpositionisnotdeterminedcorrectly,

themotorwillaccelerateinanuncontrolledmanner.

This can lead todamagetothemechanicalsystem.

Makesuretocarefullytesttheautocommutation

function.Varythestartposition.Even if

autocommutation has not been performed, the drive

can be “made to rotate” in up to 50 % of cases.

Enable speed tracking error monitoring (P 744[0] -

SDiffMax, Section "Speed- / velocity limits" on page

253. This monitoring function provides extensive

protection against uncontrolled movement.

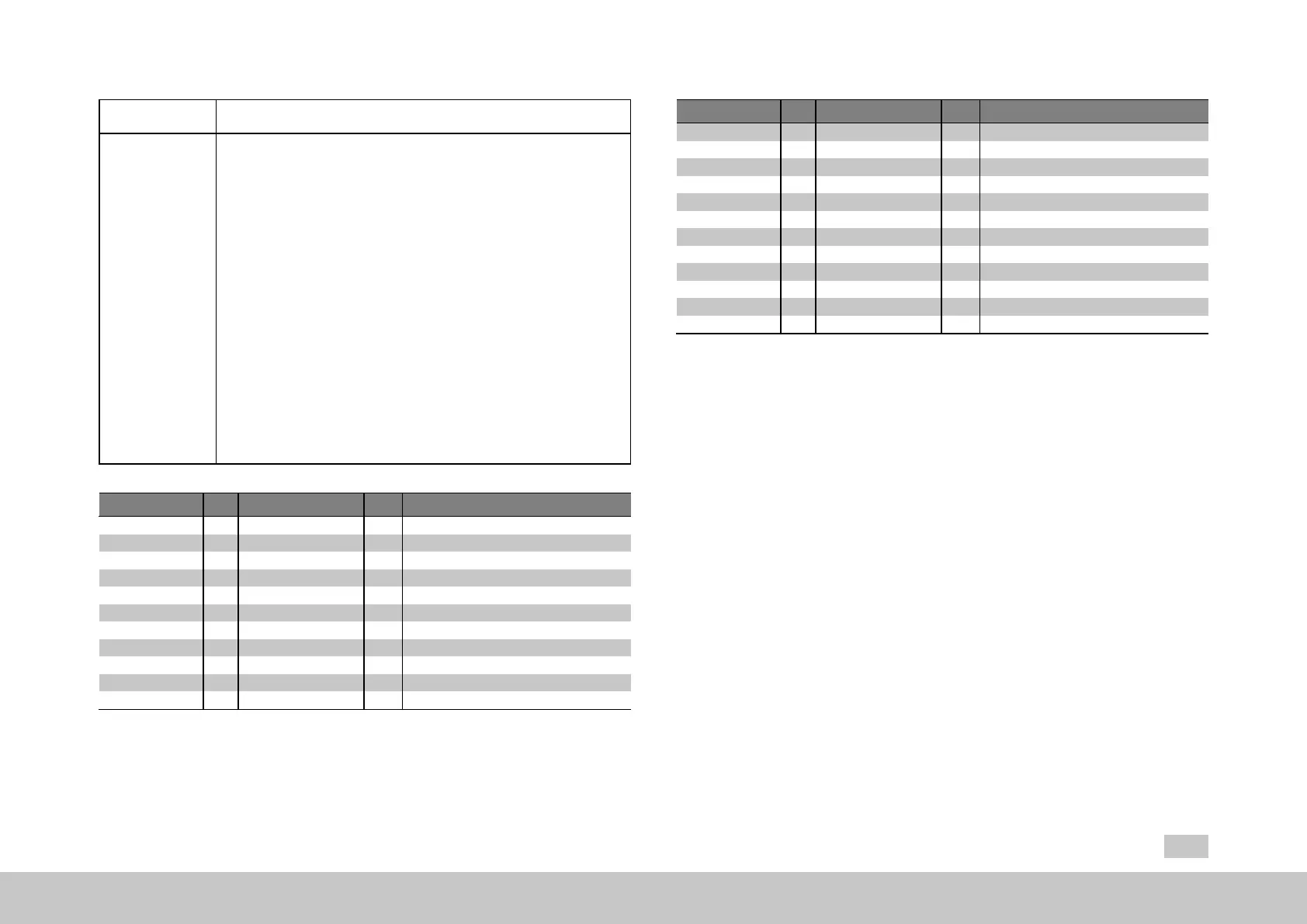

ID Index Name / Setting Unit Description

365 0 CON_ICOM_AutoOn autorecommutationafterselectedevent

366 0 CON_ICOM_RefSpeed rpm commutationdetection:scalingofcontrolgain

390 0 CON_ICOM Autocommutation:Controlwordforselection

Off(0) Functiondisabled

IENCC(1) Currentinjection

LHMES(2) Saturationofinductanceevaluated

IECSC (3) Not yet implemented

IECON(4) Currentinjection,minimizedmovement

HALLS (5) Not yet implemented

HALLSDIGITAL(6) DigitalHallsensor

HALLSDIGITAL2(7) DigitalHallsensor(alternateprocess)

Table 7.27: “Auto commutation” parameters

MOOG

ID

No.: CB40859-001 Date: 02/2018

MSD Servo Drive- Device Help

145

7 Control

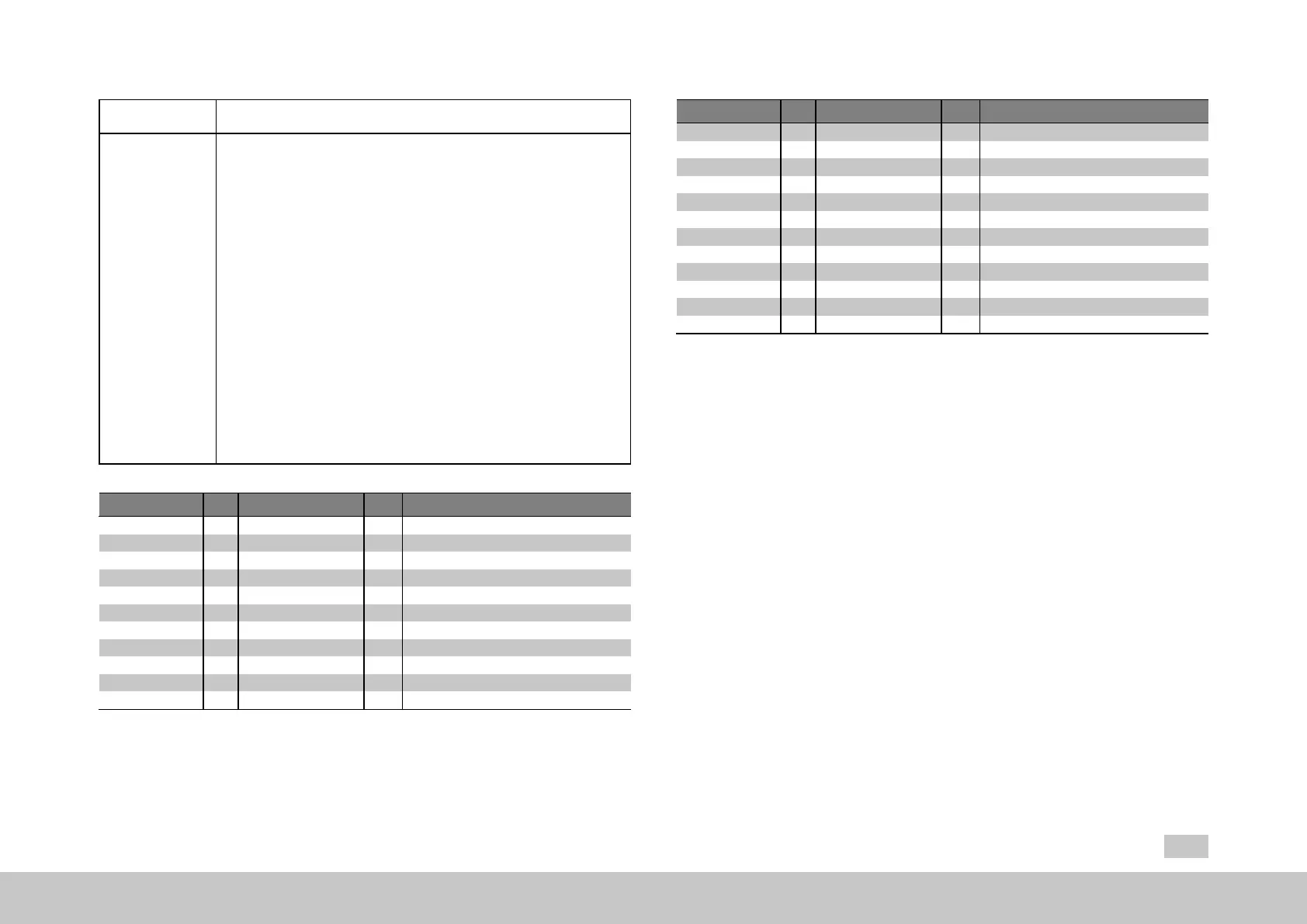

ID Index Name / Setting Unit Description

391 0 CON_ICOM_KpScale % commutationdetection:scalingofcontrolgain

392 CON_ICOM_Time commutationdetection:times

392 0 CON_ICOM_Time ms

392 1 CON_ICOM_Time ms

392 2 CON_ICOM_Time ms

392 3 CON_ICOM_Time ms

393 CON_ICOM_Current commutationdetection:currents

393 0 CON_ICOM_Current A

393 1 CON_ICOM_Current A

394 CON_ICOM_Check Monitoringautocommutation

394 0 LIMIT degree Autocommutation:Angleerrorlimit

394 1 ActVal degree Autocommutation:Actualangleerrorvalue

Table 7.27: “Auto commutation” parameters (continue)

Loading...

Loading...