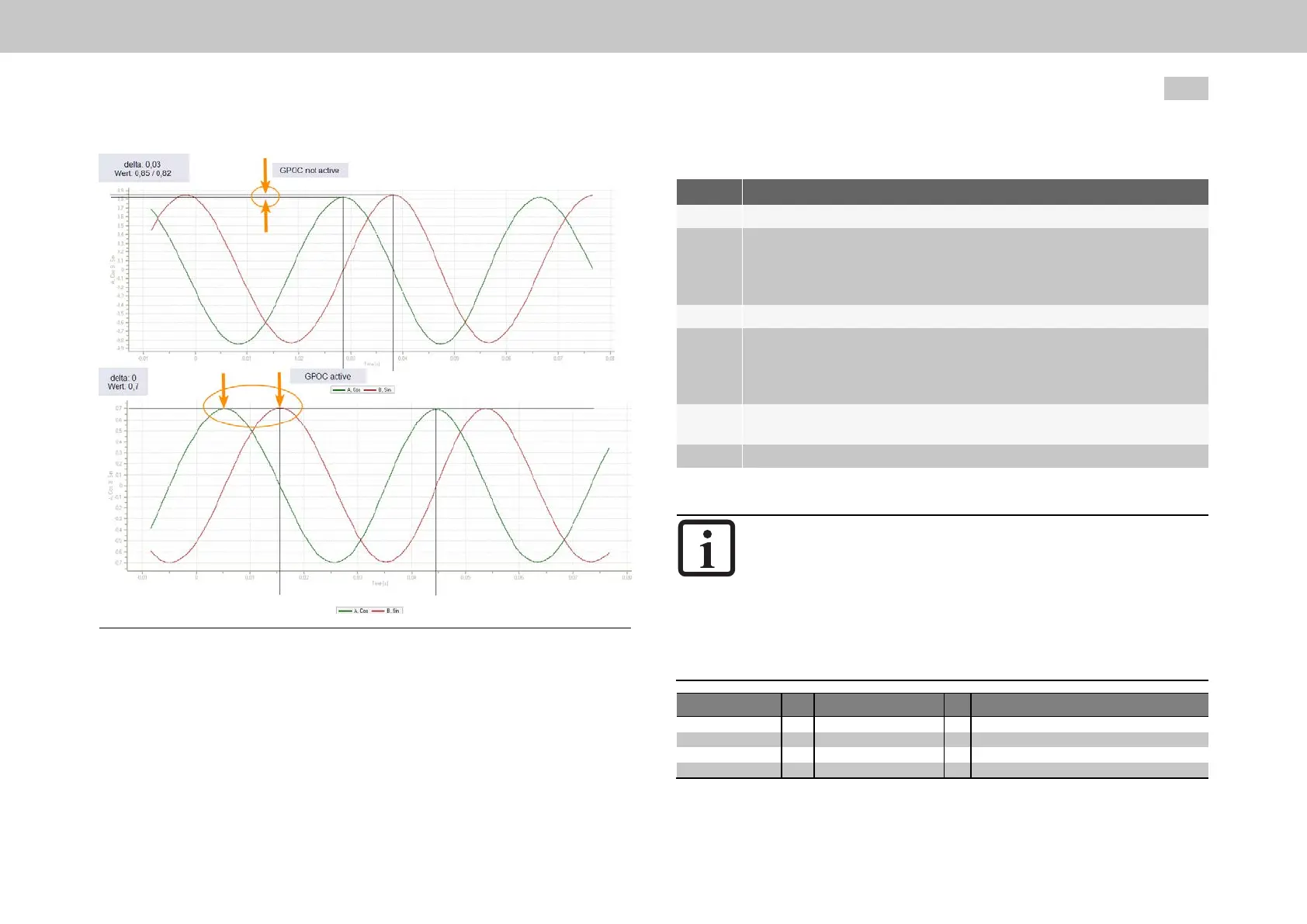

Fig. 6.4: Track signals with and without GPOC

MOOG

ID

No.: CB40859-001 Date: 02/2018

MSD Servo Drive- Device Help

72

6 Encoder

Procedure

Step Action

1. Openthemanualmodewindowandsetspeed-controlledmode.

2.

Motoroperatedatconstantspeed

Resolver:1000rpm

Sin/Cosincrementalencoder:1to5rpm.

3. SetP 549[0] - ENC_CH1_Corrto"ADAPT(2)=Autocorrection"

4.

Waitabout1–3minutes.Duringthistime,thecompensationalgorithms

willreachtheirsteadystate.Speed ripple should decrease after about 1

minute.Thiscanbemonitoredwiththeactualspeedvalue in the scope

orwithP 550 - ENC_CH1_CorrVal.

5.

SetP 549[0] - ENC_CH1_Corrto"CORR(1)=Correctionwithsaved

values".

6. Saveinthedevice

Table 6.16: Configuring and activating GPOC

NOTE

Theroutinecanalsobekeptenabledpermanently.However,this

approachislessrobustandrequirescarefultestingtodetermine

whethertheimprovedencoderevaluationqualitywillactuallybe

maintainedduringcontinuousoperation.

TheGPOCroutinewilldeterminetheparametersindividuallyfor

eachencoder.Ifthemotorisreplaced,theGPOCroutinemustbe

activatedagain.

ID Index Name Unit Description

549 0 ENC_CH1_Corr Signalcorrectiontype

550 ENC_CH1_CorrVal Signalcorrectionvalues

550 0 OffsetA Offset,trackA-cosine

550 1 OffsetB Offset,trackB-sine

Table 6.17: Signal correction (GPOC) parameters for channel 1 (X7)

Loading...

Loading...