53

F3SG-SR

User’s Manual

Chapter2 PSDI

System Operation and Functions

E

2-10-2. Factory Default Setting

The PSDI function is set disabled.

2-10-3. Setting Change using Intelligent Tap

It is unable to change the setting of this function using the DIP Switch of the Intelligent Tap.

2-10-4. Setting Change using SD Manager 3

The following setting can be made using SD Manager 3.

* Set the minimum pressing time of the reset switch and pre-reset switch. The same minimum pressing time is applied to both

the switches.

It is recommended that the Position 2 of the DIP Switch be set at OFF (DIP Switch Disabled).

For the details of the setting change using SD Manager 3, refer to Chapter 4 Setting with SD Manager 3.

Function Initial value Configurable value or numerical range

PSDI function Disabled Disable/Single break/Double break

Minimum pressing time of reset switch * 100 ms 100 to 500 ms in 100-ms increments

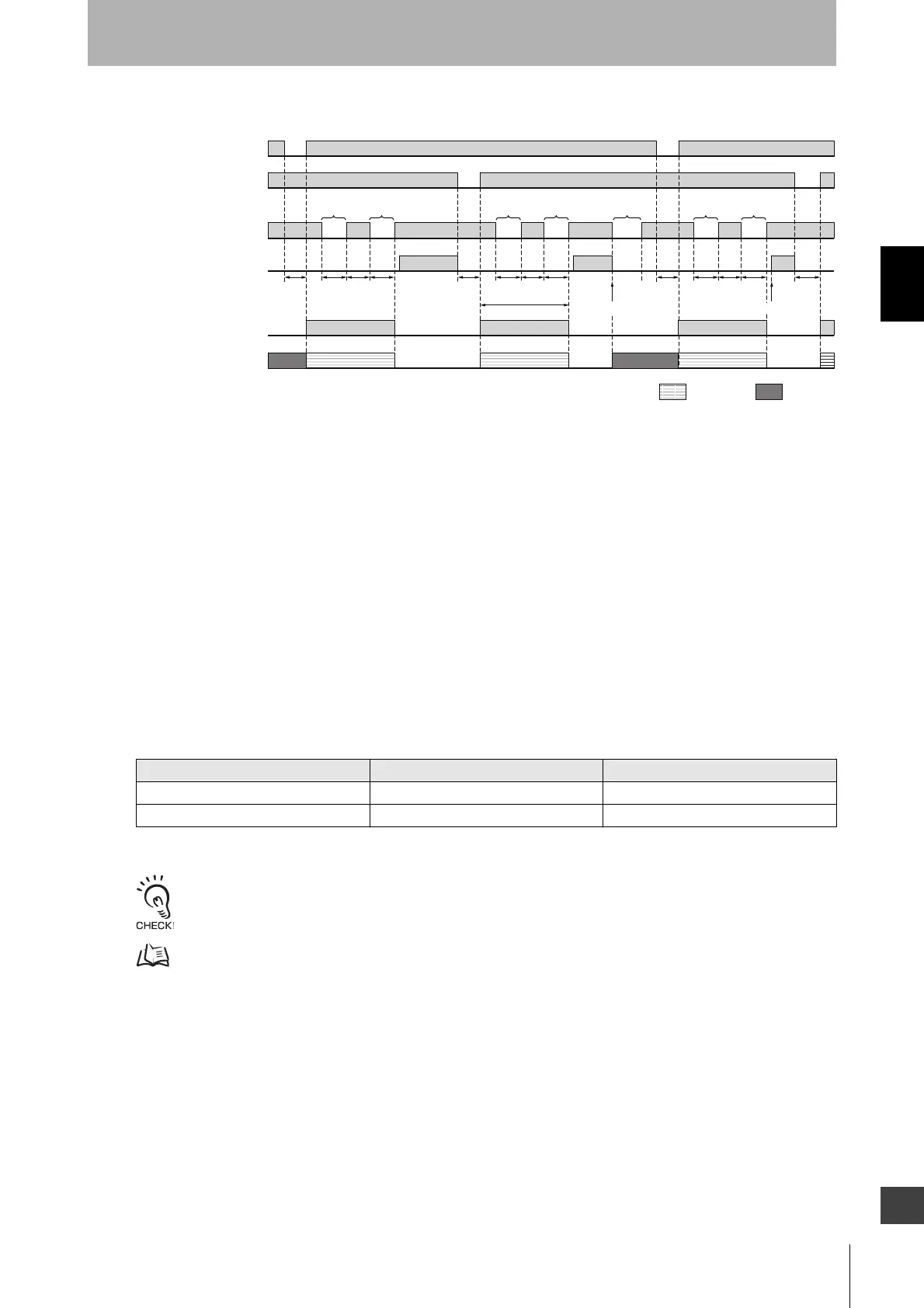

T1

min.

T1

min.

T2

min.

Dummy

break

Dummy

break *

1

Dummy

break *

1

Unintended

break

Feeding

parts

Removing

parts

Feeding

parts

T3

min.

T4

min.

T2

min.

T3

min.

T6

Machine stops

T4

min.

T2

min.

T3

min.

T4

min.

T5

以上

T5

min.

Double Break

Reset switch (S1)

Pressposition

switch(S3)

OSSD

T1: Minimum pressing time of reset switch, configurable by 100 ms in a range of 100-500 ms

T2: Minimum break time (300 ms)

T3: Minimum unblocked time during the time from removing to feeding parts. T3 = T1

T4: Minimum break time (300 ms)

T5: Minimum pressing time of press position switch. T5 = T1

T6: Wait time until double break is complete (30 s or less)

*1. When the machine is stopped by unintended block in the middle of pressing of parts, operation of the reset switch (S1)

and then double dummy break are needed for reinitiation of the machine cycle.

*2. When Auxiliary Output is set to PSDI Information by the SD Manager 3.

AUX*

2

SEQindicator

(yellow)

Beamstate

Unblocked

Blocked

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON 1 time Solid-ON

Machine restarts

Loading...

Loading...