7.2.1.4 Controlword in Homing Mode

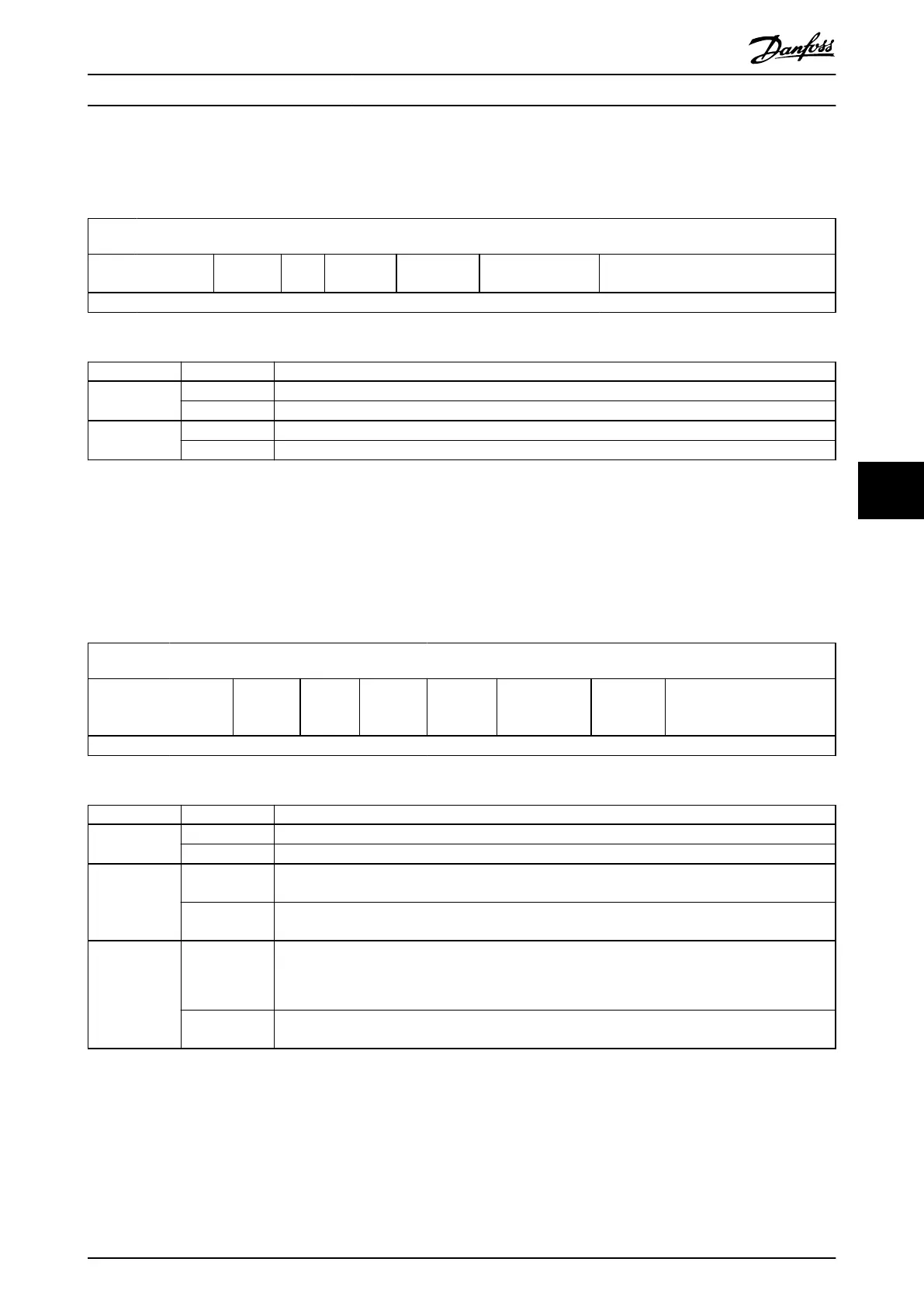

Table 7.13 shows the structure of the Controlword. Table 7.14 denes the values for bits 4 and 8 of the Controlword.

15 10 9 8 7 6 4 3 0

See Table 7.2

Reserved

(0)

Halt

See

Table 7.2

Reserved (0)

Homing operation

start

See Table 7.2

MSB LSB

Table 7.13 Controlword in Homing Mode

Bit Value Denition

4 0 Do not start homing procedure.

1 Start or continue homing procedure.

8 0 Enable bit 4.

1 Stop axis according to halt option code (see chapter 7.20.7 Parameter 50-47: Halt Option Code (0x605D)).

Table 7.14 Denition of Bits 4 and 8

7.2.1.5 Controlword in CAM Mode

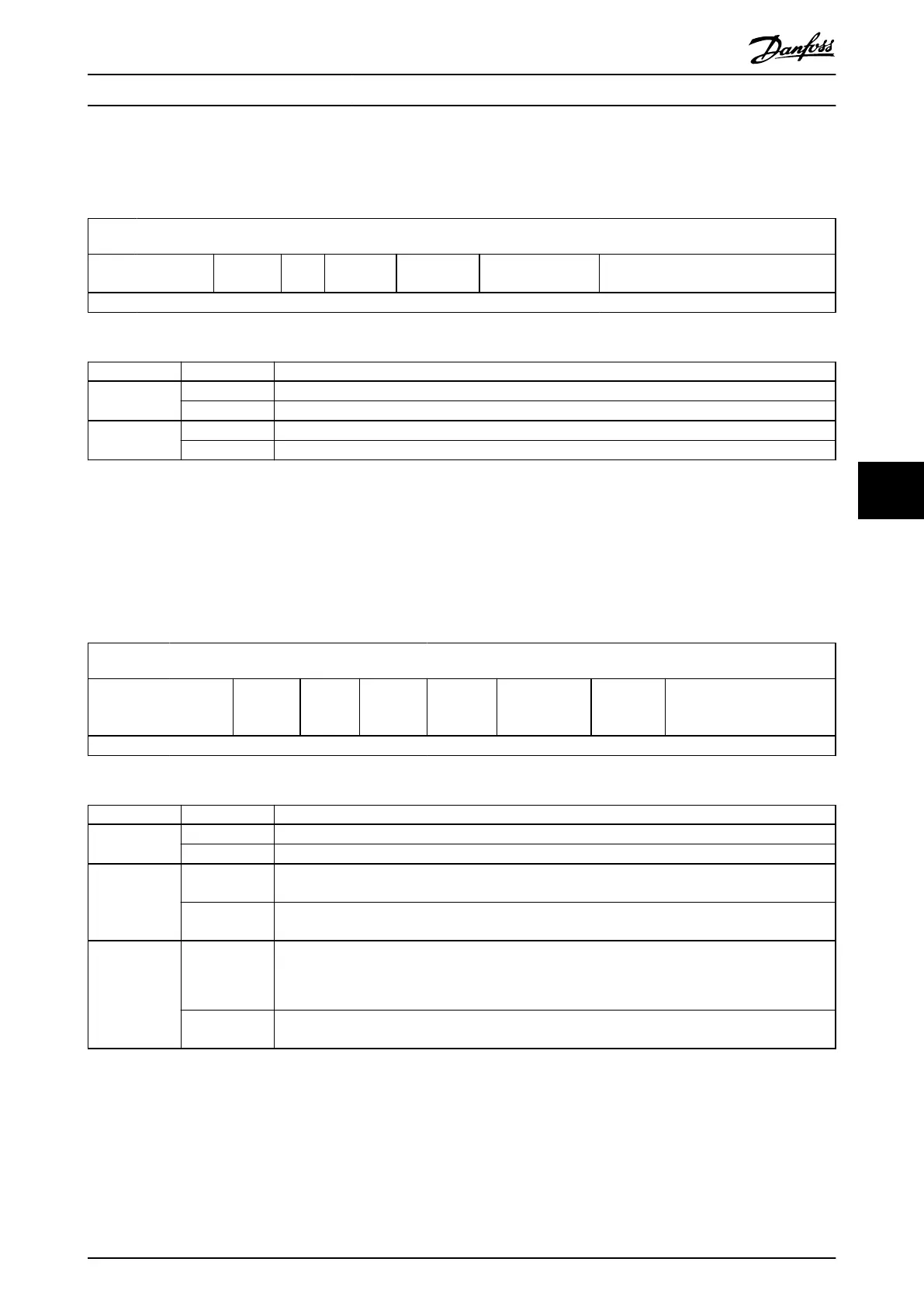

Table 7.15 shows the structure of the Controlword. The rising edge of bit 4 starts the CAM prole activation request.

Table 7.16 denes the values for bits 5, 6, and 9 of the Controlword. It is assumed that the activation request of a CAM is

edge-triggered 0→1, otherwise the axis has no clear point in time when to activate a new CAM

prole, or to reactivate a

CAM prole without any content changes.

15

10 9 8 7 6 5 4 3 0

See Table 7.2

Use blend

distance

Reserved

(0)

See

Table 7.2

Control

parameter

source

Change CAM

immediately

New CAM See Table 7.2

MSB LSB

Table 7.15 Controlword in CAM Mode

Bit Value Denition

5 0 Currently active CAM prole is nished rst (target reached).

1 Next CAM prole is started immediately.

6 0 Control parameter set selection uses the manufacturer-specic bit of the Controlword (bit 15). This is

default behavior as in other modes of operation.

1 Control parameter set selection is done automatically inside the CAM prole. The manufacturer-specic

bit of the Controlword (bit 15) for selection is ignored by the axis.

9 0 Automatically blend to the beginning of the new CAM:

•

Basic CAM: 1st data point

•

Advanced CAM: starting node

1 Uses value of object 0x380A (see chapter 7.14.11 Parameter: Minimum Blending Distance (0x380A)) as the

minimum length for blending to a new CAM.

Table 7.16 Denition of Bits 5, 6, and 9

Servo Drive Parameter Descr... Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 235

7 7

Loading...

Loading...