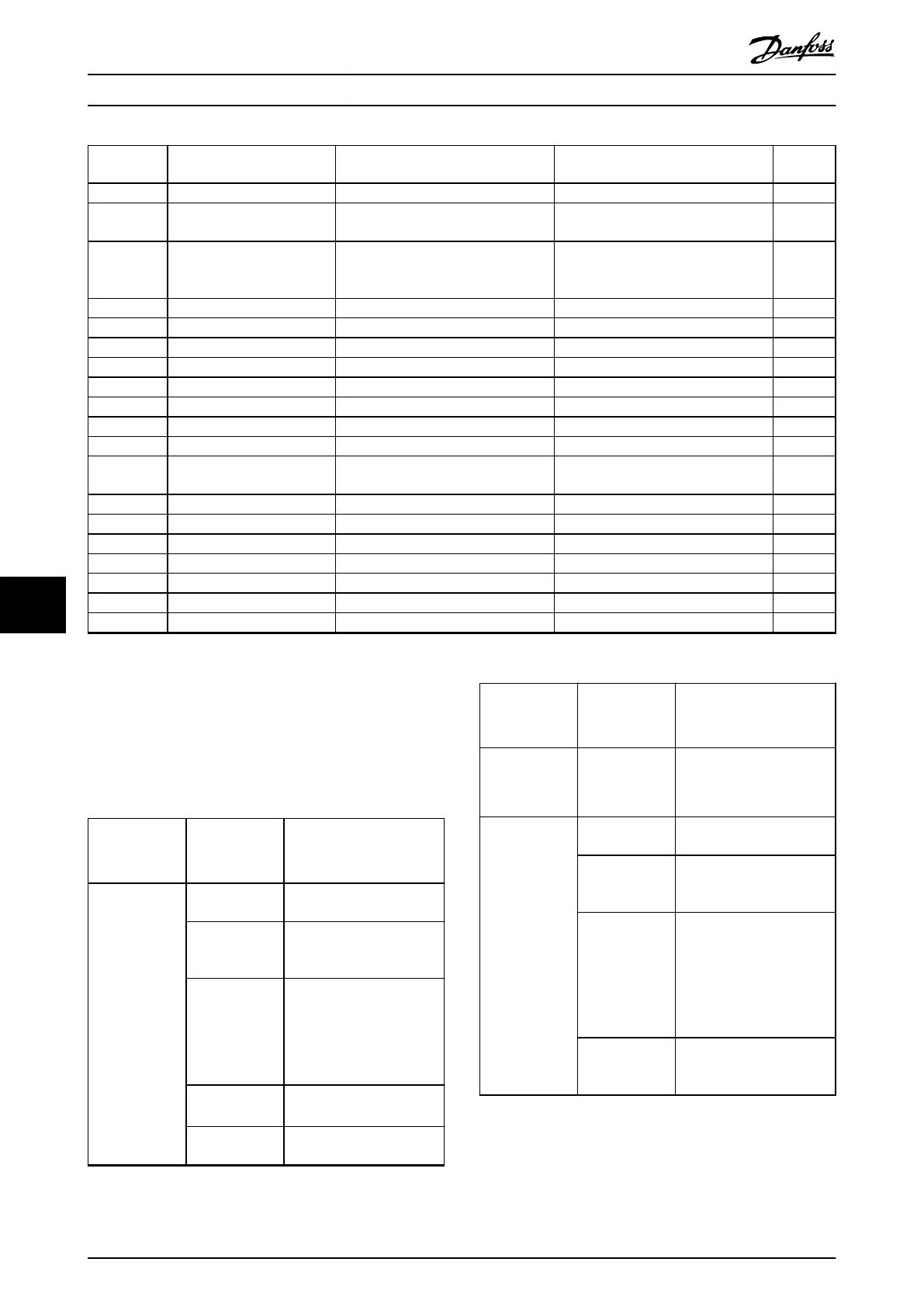

Signal ID

(hex)

Signal name PLC library -

trace constant name

Description OD object

80000008 Rotor position logical ISD51x_TRC_ROTOR_POS_ACT_VIRT Logical rotation position of motor shaft –

80000009 Following error ISD51x_TRC_PCTRL_LAG_ERROR Following error (dierence between act

value and setpoint)

–

8000000A Rotor mech angle raw ISD51x_TRC_ROTOR_POS_RAW Raw mechanical angle, not

compensated for resolver mounting to

pole, not mirrored

–

8000000B Rotor speed relative – Rotor speed relative –

8000000E Position ctrl set ISD51x_TRC_PCTRL_POS_SET Setpoint of position control loop –

8000000F Logical CAM setpoint ISD51x_TRC_CAM_POS_SET Position setpoint in cam mode 0x2021

80000010 Cam velocity set ISD51x_TRC_CAM_N_SET Speed setpoint in cam mode –

80000012 Controlword ISD51x_TRC_CONTROLWORD Controlword 0x6040

80000013 Statusword ISD51x_TRC_STATUSWORD Statusword 0x6041

80000014 Motion and input status ISD51x_TRC_MOTION_AND_INPUT Motion and input status 0x2006

80000015 Cam prole status ISD51x_TRC_CAM_PROFILE_STATUS Cam prole status 0x3085

80000016 Logical CAM setpoint scaled – Position setpoint in cam mode after

slave scaling

–

80000017 CAM friction torque ISD51x_TRC_CAM_FRICTION_COMP Cam friction compensation torque –

80000020 Position actual value ISD51x_TRC_POSITION_ACTUAL_VALUE Actual position in user-dened units 0x6064

80000021 Velocity actual value ISD51x_TRC_DS402_VELOCITY_ACT_VAL Actual velocity in user-dened units 0x606C

80000022 Torque actual value ISD51x_TRC_TORQUE_ACTUAL_VALUE Actual torque ‰ of rated torque 0x6077

80000023 Following error actual value ISD51x_TRC_DS402_FOLLOW_ERR Following error in user-dened units 0x60F4

80000025 Position guide value reference ISD51x_TRC_GUIDE_REF_VAL_POS Position guide value reference 0x2062

80000026 Velocity guide value reference ISD51x_TRC_GUIDE_REF_VAL_SPEED Velocity guide value reference 0x2065

Table 9.3 Trace Signals for Servo Drive

9.3

SAB

9.3.1 Troubleshooting

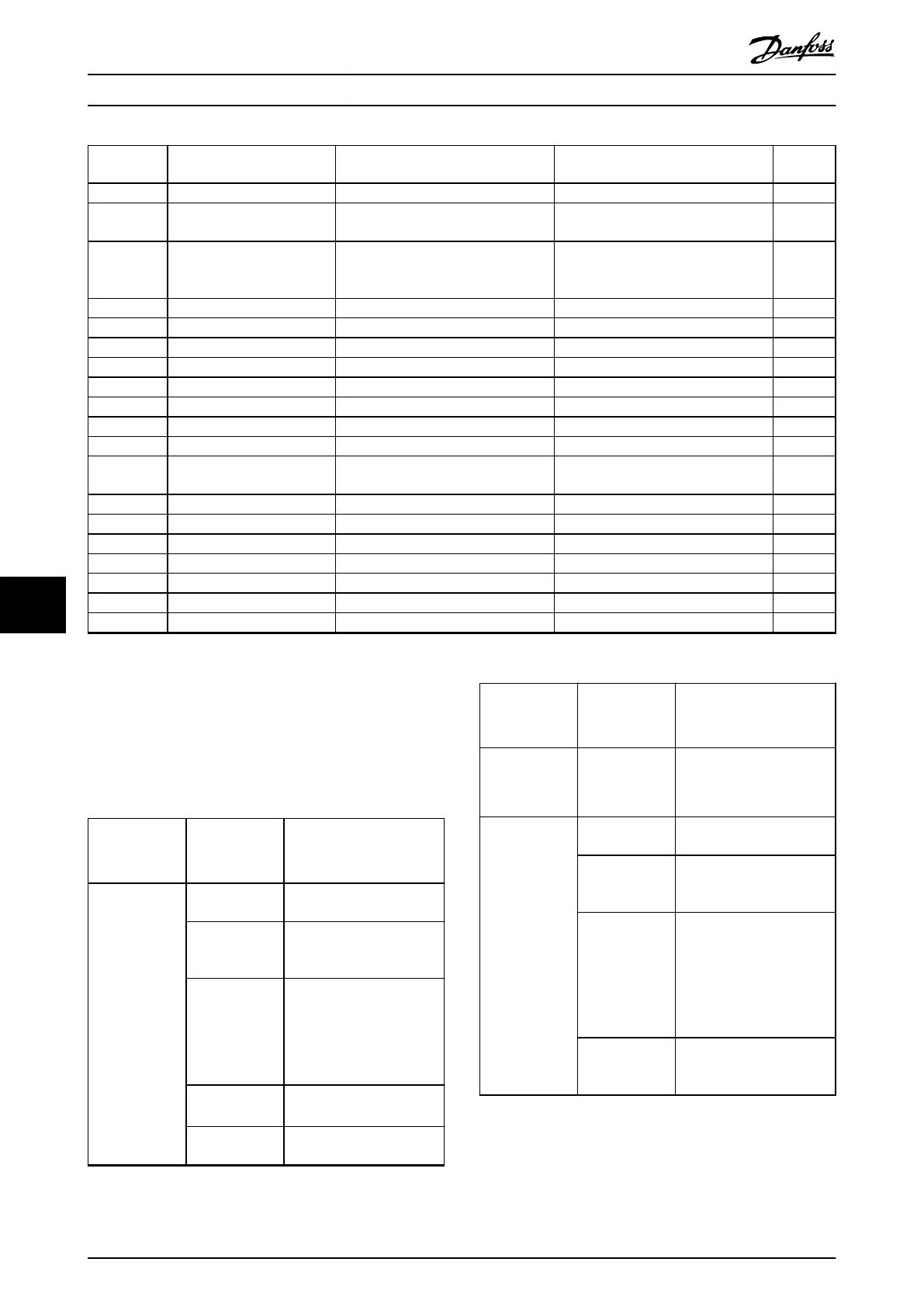

Table 9.4 lists potential faults on the SAB, their possible

causes, and actions for correcting the faults.

Fault Possible cause Possible solution

LCP display dark

or has no

function.

Missing input

power.

Check the input power

source.

Missing or open

fuses or circuit

breaker tripped.

Check the fuses and circuit

breaker.

No power to the

LCP.

•

Check the LCP cable for

proper connection or

damage.

•

Replace any faulty LCP

or connection cables.

Incorrect

contrast setting.

Press [Status] + [

▲

]/[

▼

] to

adjust the contrast.

Display is

defective.

Replace the faulty LCP or

connection cable.

Fault Possible cause Possible solution

Open power

fuses or circuit

breaker trip.

Phase-to-phase

short.

•

Check the cabling.

•

Check for loose

connections.

DC-link voltage

too high.

Brake resistor

not connected.

Check the brake resistor

cabling.

Brake resistor

too high

resistance.

Check if the lowest

resistance value has been

entered.

Several servo

drives are

decelerating

with insucient

ramp time.

•

Avoid simultaneous

deceleration of several

servo drives.

•

Change the deceleration

speed of the servo

drives.

Brake resistor

functionality not

activated.

Activate the brake function.

Diagnostics

VLT

®

Integrated Servo Drive ISD

®

510 System

372 Danfoss A/S © 01/2017 All rights reserved. MG36D102

99

Loading...

Loading...