Enumeration MC_SYNC_MODE_ISD51x denes the synchro-

nization types for the gear in process.

Name Description

mcShortest_ISD51x Synchronization is done to have the

shortest way for the slave.

mcCatchUp_ISD51x Synchronization is done to catch up to

the master axis (synchronization to current

master cycle).

mcSlowDown_ISD51x Synchronization is done to slow down to

the master axis (synchronization 1 master

cycle later).

Table 6.50 Enumeration MC_SYNC_MODE_ISD51x

6.5.5.11 DD_GetInertia_ISD51x

This function block is used to determine the inertia of the

servo drive system. Only activate the function block when

the axis is in state Standstill. Only values >0 are allowed for

the inputs VelocityLimit and TorqueLimit.

The command is transferred and executed immediately.

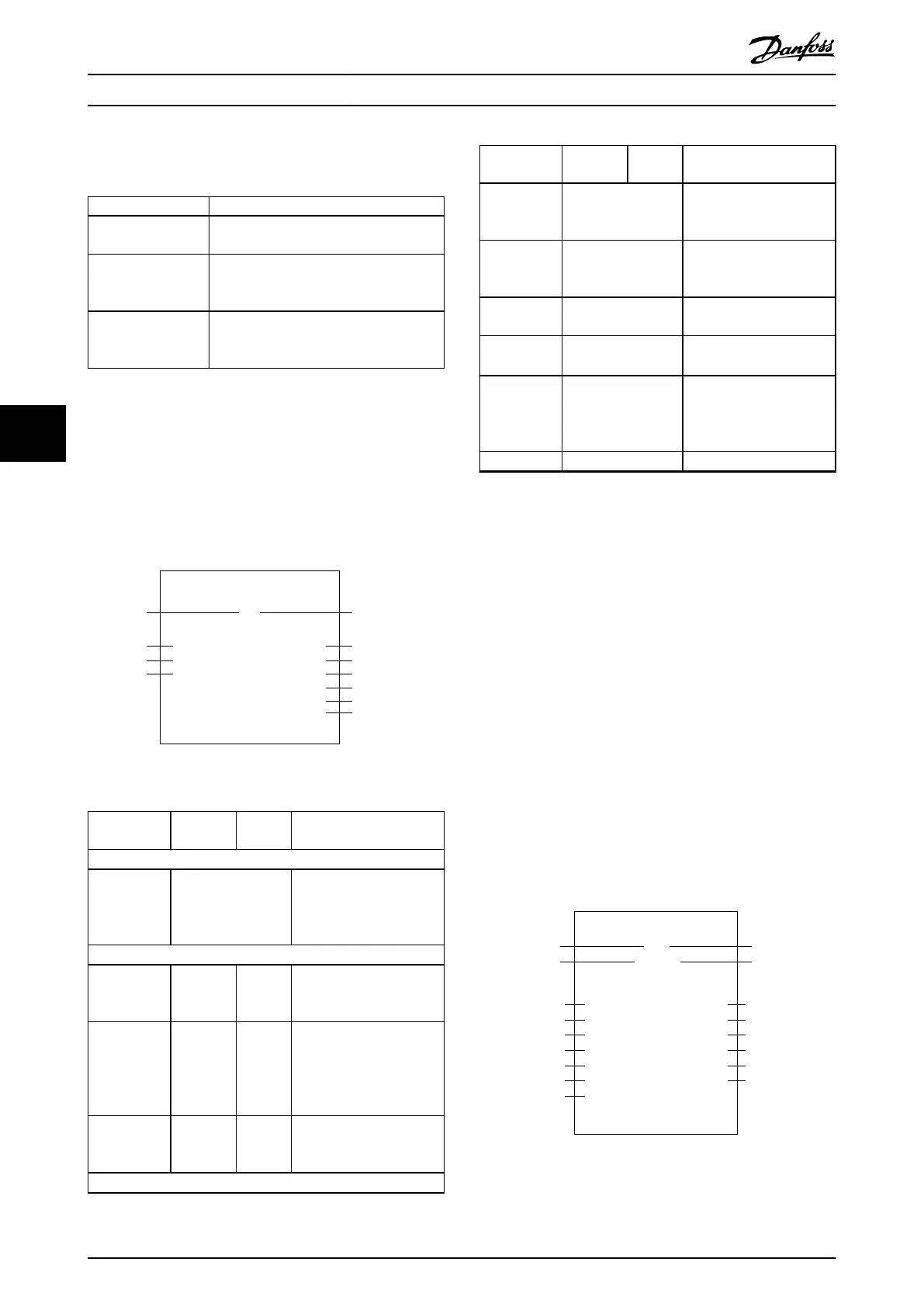

DD_GetInertia_ISD51x

Axis

ExecuteBOOL

AXIS_REF_-

ISD51x

VelocityLimitUDINT

TorqueLimitUINT

BOOLDone

BOOLBusy

BOOLError

BOOLCommandAborted

DD_ERROR_ISD51xErrorInfo

REALInertia

130BE264.10

Illustration 6.71 DD_GetInertia_ISD51x

Variable

name

Data type Default

value

Description

VAR_IN_OUT

Axis AXIS_REF_ISD51x Reference to the axis.

See

chapter 6.5.4.1 AXIS_REF_IS

D51x.

VAR_INPUT

Execute BOOL FALSE Starts the inertia

measurement at rising

edge.

VelocityLimit UDINT 0 Maximum velocity used

during the measurement

[user-dened velocity unit].

Only values >0 are

allowed.

TorqueLimit UINT 0xFFFF Maximum torque used

during this motion [mNm

(Millinewtonmeter)].

VAR_OUTPUT

Variable

name

Data type Default

value

Description

Done BOOL The inertia measurement

has completed successfully

and the value is available.

Busy BOOL The function block is not

nished and new output

values are to be expected.

CommandA-

borted

BOOL Command is aborted by

another command.

Error BOOL An error has occurred

within the function block.

ErrorInfo DD_ERROR_ISD51x Error identication and

instance identier.

See chapter 6.5.2.3 Error

Indication.

Inertia REAL Measured inertia [kg m²].

Table 6.51 DD_GetInertia_ISD51x

6.5.6 Drive – CAM Operation

6.5.6.1 MC_CamTableSelect_ISD51x

This function block selects the CAM tables by setting the

connections to the relevant tables. When the Done output

is set, the axis internal buer dened by CamTableID is

valid and ready for use in a MC_CamIn_ISD51x function

block. The sending and parsing of the CAM can take some

time.

The function block sends the information to the axis.

Execute this function block for every axis if >1 axis must

follow the same CAM. This function block only writes the

CAM information to the servo drive and does not activate

the CAM. Use function block MC_CamIn_ISD51x to activate

the CAM. If the CAM prole contains a pattern alignment,

the pattern le must be given to input PatternFile. If there

is no pattern alignment inside the CAM, use an empty

string.

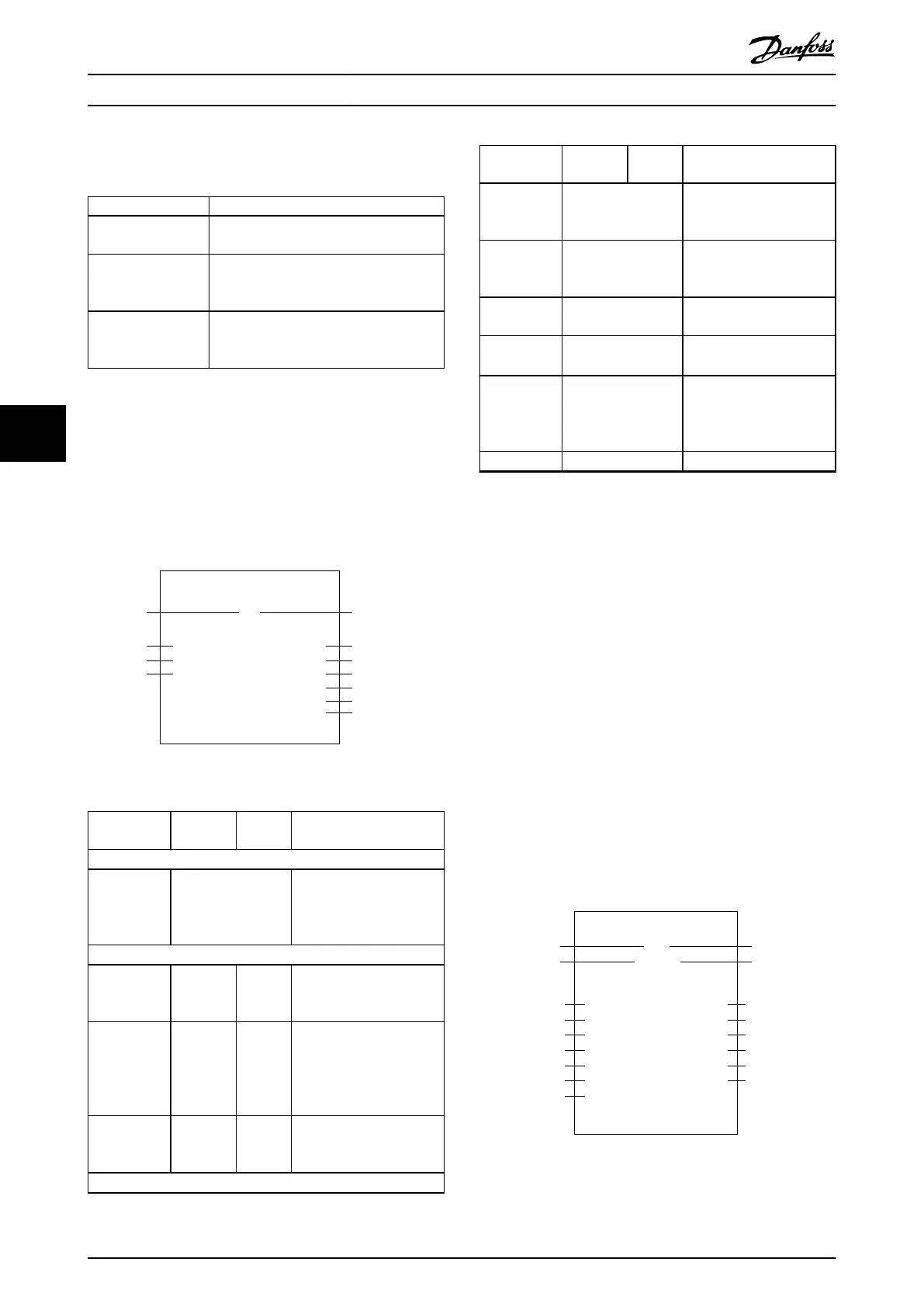

MC_CamTableSelect_ISD51x

Slave

ExecuteBOOL

AXIS_REF_ISD51x

CamTable

STRING(80)

BOOLDone

BOOLBusy

DD_ERROR_ISD51xErrorinfo

BOOL

WORDParseError

DWORDParseErrorDebug

Error

CamTableIDUSINT

SlaveAbsoluteBOOL

CyclicBOOL

PathE_OpenPath

PatternFileSTRING(80)

MasterAbsoluteBOOL

Illustration 6.72 MC_CamTableSelect_ISD51x in TwinCAT

®

Programming

VLT

®

Integrated Servo Drive ISD

®

510 System

212 Danfoss A/S © 01/2017 All rights reserved. MG36D102

6

6

Loading...

Loading...