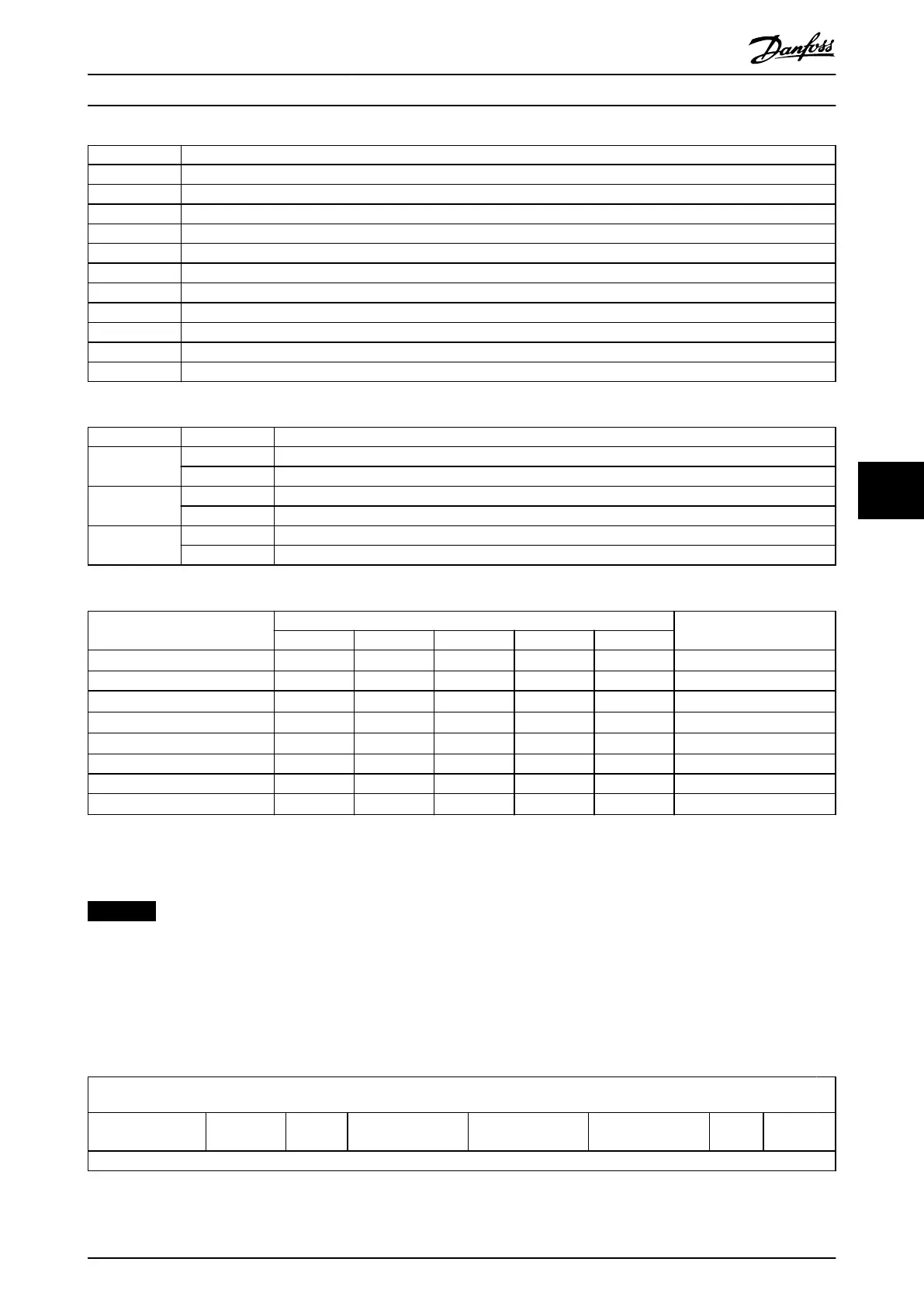

ms Manufacturer-specic

r Reserved

oms Operation mode specic

h Halt

fr Fault reset

eo Enable operation

qs Quick stop

ev Enable voltage

so Switch on

cs Control set selection

do Set/reset the digital output

dcs Digital CAM switching functionality enabled/disabled

Table 7.3 Denition of Controlword Bits

Bit Value Denition

11 0 Digital CAM switching functionality must be disabled (see chapter 2.5.1 Digital CAM Switch).

1 Digital CAM switching functionality must be enabled (see chapter 2.5.1 Digital CAM Switch).

12 0 Digital output is cleared.

1 Digital output is set.

15 0 Control parameter set 1 is used (objects 0x2012 and 0x2013; see chapter 2.3.6 Control Loops).

1 Control parameter set 2 is used (objects 0x2014 and 0x2015; see chapter 2.3.6 Control Loops).

Table 7.4 Manufacturer-specic Bits in Controlword

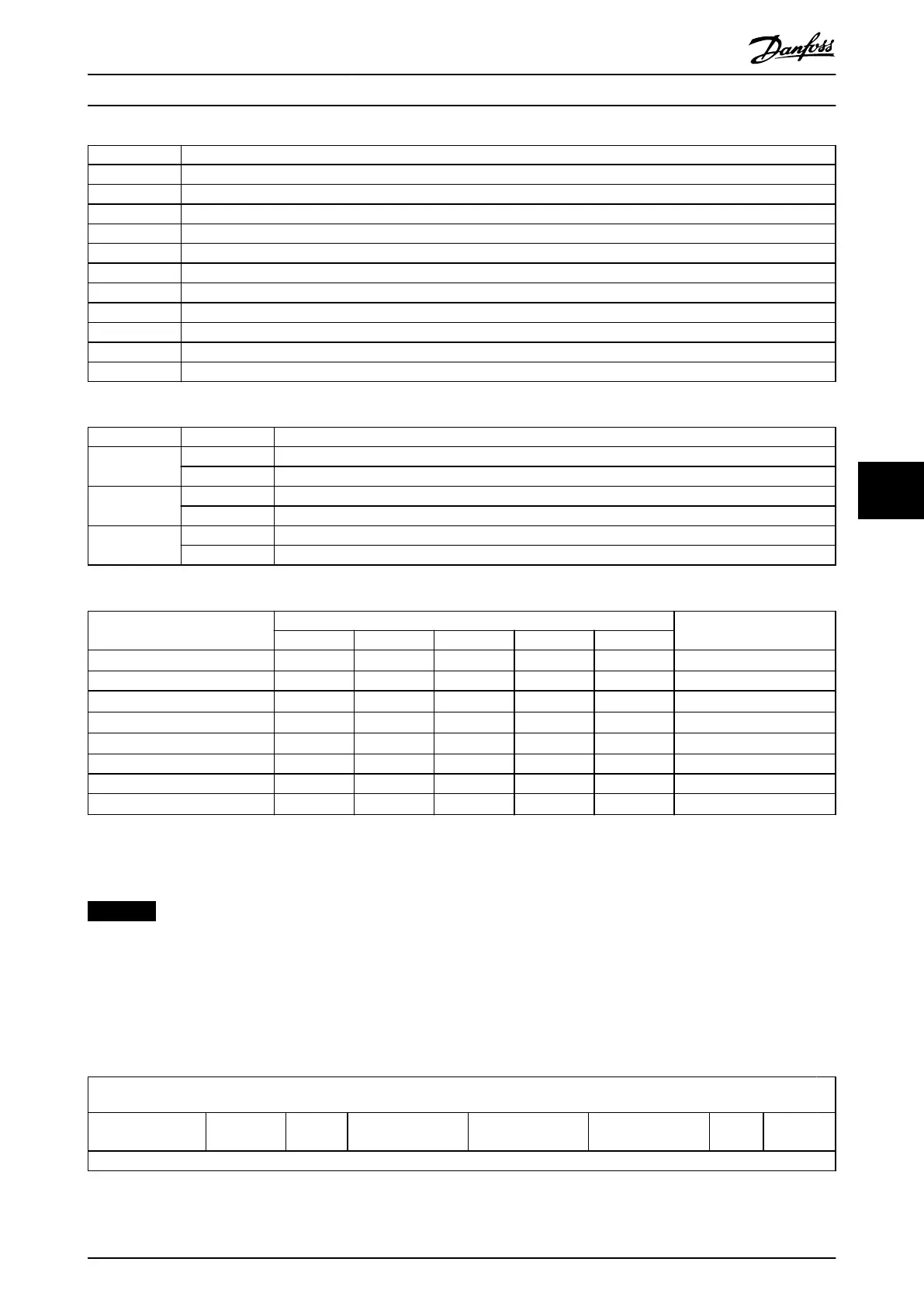

Command

Controlword bits

Transitions

Bit 7 Bit 3 Bit 2 Bit 1 Bit 0

Shutdown 0

X

1)

1 1 0 2, 6, 8

Switch on 0 0 1 1 1 3

Switch on and enable operation 0 1 1 1 1

3, 4

2)

Disable voltage 0

X

1)

X

1)

0

X

1)

7, 9, 10, 12

Quick stop 0

X

1)

0 1

X

1)

7, 10, 11

Disable operation 0 0 1 1 1 5

Enable operation 0 1 1 1 1 4, 16

Fault reset

0→1

X

1)

X

1)

X

1)

X

1)

15

Table 7.5 Command Coding

1) X denotes Don’t care.

2) Automatic transition to Enable operation state after executing Switched on state functionality.

NOTICE

See chapter 2.3.1 State Machine for the relevant transitions.

7.2.1.1 Controlword in Prole Position Mode

Table 7.6 shows the structure of the Controlword. Table 7.7 denes the values for bit 4, 5 and 9 of the Controlword. Table 7.8

denes the values for bit 6 and 8 of the Controlword. If no positioning is in progress, the rising edge of bit 4 starts the

positioning of the axis. If positioning is in progress, the values given in Table 7.7 dene the behavior.

15

10 9 8 7 6 5 4 3 0

See Table 7.2

Change on

setpoint

Halt See Table 7.2 Abs/rel

Change set

immediately

New

setpoint

See

Table 7.2

MSB LSB

Table 7.6 Controlword for Prole Position Mode

Servo Drive Parameter Descr... Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 233

7 7

Loading...

Loading...