the servo drive, which performs velocity control and

torque control.

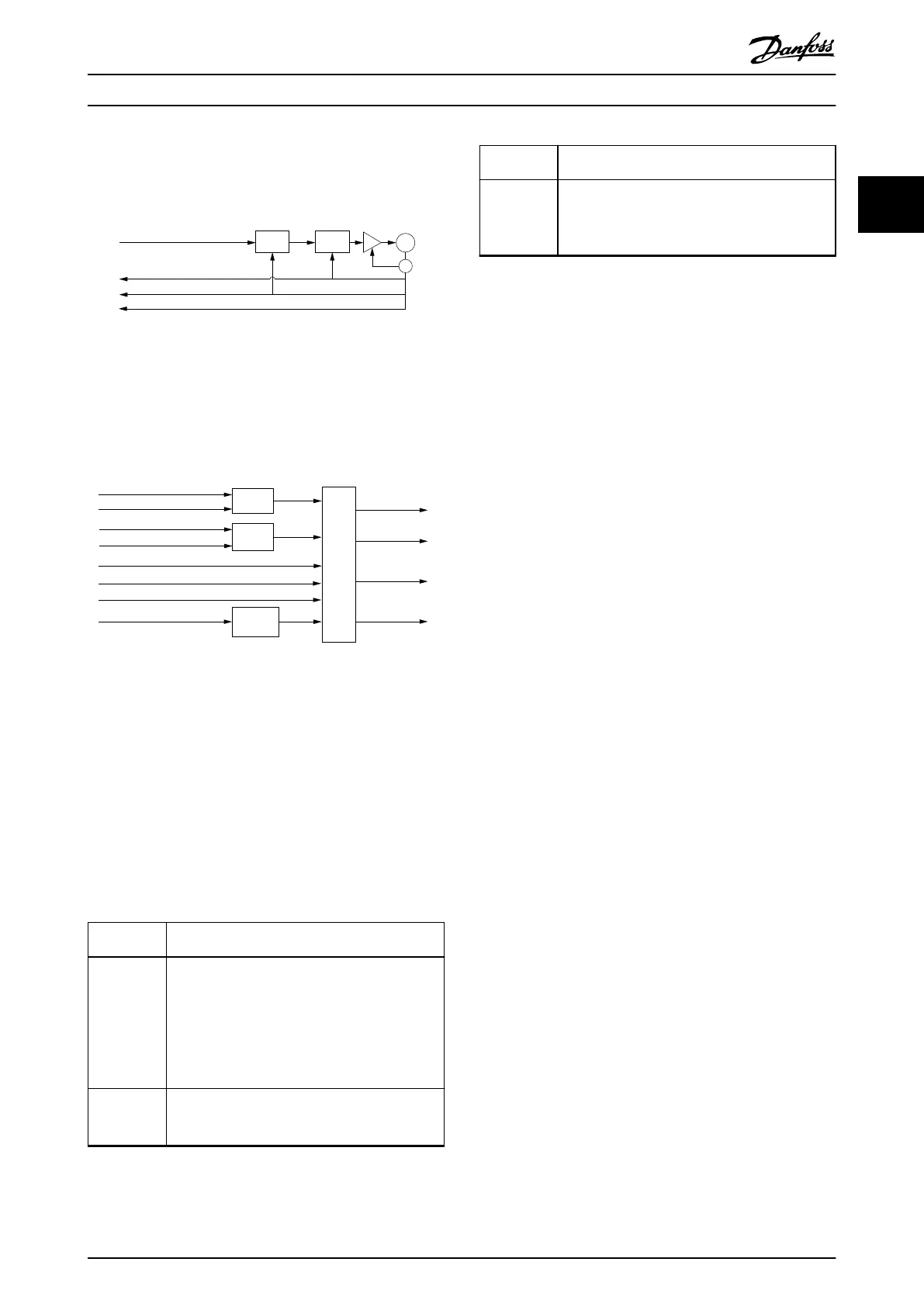

Velocity

control

Torque

control

M

s

Target velocity (0x60FF)

Torque actual value (0x6077)

Velocity actual value (0x606C)

Position actual value (0x6064)

Illustration 2.118 Cyclic Synchronous Velocity Mode Overview

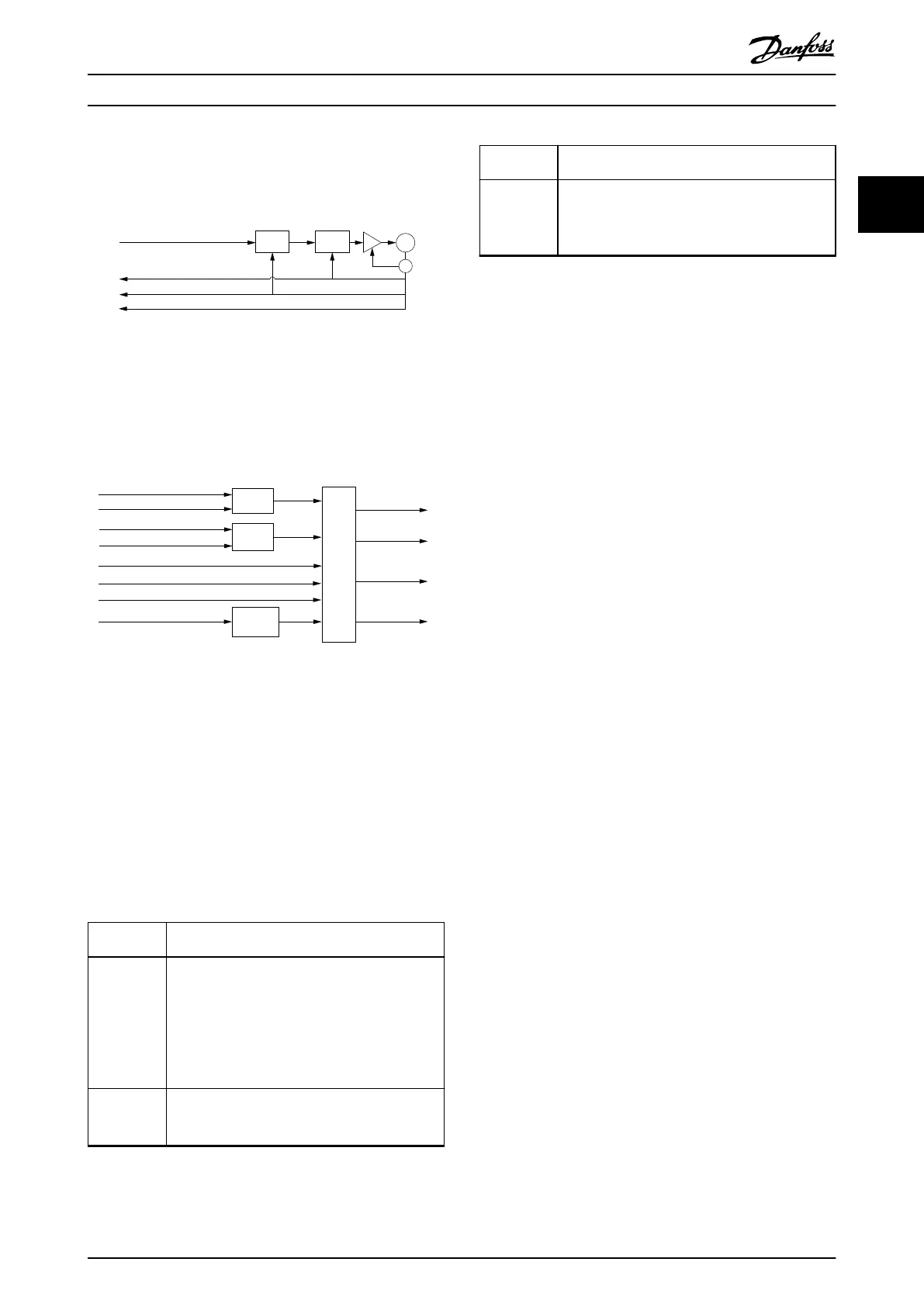

Illustration 2.119 shows the inputs and outputs of the servo

drive control function. The input value (from the control

function point of view) is the target velocity.

130BF264.10

Drive

control

function

Multiplier

Multiplier

Minimum

comparator

Target

velocity

Target velocity (0x60FF)

Torque

limit

Position actual

value (0x6064)

Velocity actual

value (0x606C)

Torque actual

value (0x6077)

Following error

actual value

(0x60F4)

Max torque (0x6072)

Drive mirror mode (0x2016,02)

Drive mirror mode (0x2016,02)

Max motor speed (0x6080)

Quick-stop deceleration (0x6085)

Quick-stop option code (0x605A)

Interpolation time period (0x60C2)

Illustration 2.119 Cyclic Synchronous Velocity Control Function

The servo drive supports limitation of motor speed and a

quick stop function for emergency reasons. The torque is

limited as well. The interpolation time period denes the

time period between 2 updates of the target velocity

and/or additive velocity and is used for intercycle interpo-

lation. The position actual value is used as mandatory

output to the control device. The PLC calculates the actual

velocity from the changes to the actual position changes.

All values are given in user-dened units.

2.5

Motion Functions

Function Description

Digital CAM

switch

This functionality controls whether the digital

output is enabled or disabled, depending on the

axis position. It performs a function comparable

to switches on a motor shaft. Forward and

backward movements of the axis position are

allowed. On and o compensation and hysteresis

can be parameterized.

ISD touch

probe

This functionality stores the position actual value

at a rising or falling edge of the congured digital

input.

Function Description

Guide value The guide value is used in all synchronous modes

of operation (CAM mode and Gear mode). It is

used as the master position within the

synchronous modes.

Table 2.57 Motion Functions

2.5.1 Digital CAM Switch

This functionality controls whether the digital output is

enabled or disabled, depending on the axis position. It

performs a function comparable to switches on a motor

shaft. Forward and backward movements of the axis

position are allowed. On and o compensation and

hysteresis can be parameterized.

The digital CAM switches are stored and handed over to

the servo drive using the contents of an XML le. The

content is stored automatically in the servo drive. There is

only 1 conguration for the digital CAM switches and a

maximum of 100 switches are supported.

The calculation of the digital CAM switches is based on the

Position actual value (see chapter 7.7.5 Parameter 50-03:

Position Actual Value (0x6064)) in all modes of operation

except CAM mode. In CAM mode, the calculation is based

on the Logical CAM position (see chapter 7.14.12 Parameter:

Logical CAM Position (0x2020)). The cyclic usage of switches

is based on the range of the Position actual value and/or

the Logical CAM position.

Information about the state of the digital CAM switching

functionality is given in object 0x2005 (see

chapter 7.22.13 Parameter 50-07: Overlaying Motion Status

(0x2005)).

A compensation time with which the switching on (see

chapter 7.17.1 Parameter: On Compensation (0x3840)) or the

switching

o (see chapter 7.17.2 Parameter: O Compen-

sation (0x3841)) can be advanced or delayed in time.

A hysteresis can be dened by using object 0x3842 (see

chapter 7.17.3 Parameter: Hysteresis (0x3842)) to avoid

jittering around the switching point.

To use the digital CAM switch, transfer the le content to

object 0x3844 (see chapter 7.17.5 Parameter: Digital CAM

Switches Data (0x3844)). Afterwards, parse the prole using

object 0x3843 (see chapter 7.17.4 Parameters: Digital CAM

Switch Parsing Control (0x3843)). When the status signals

that the data is valid, the functionality can be enabled by

using the Controlword (see chapter 7.2.1 Parameter 16-00

Controlword (0x6040)).

Servo Drive Operation Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 79

2 2

Loading...

Loading...