9 Diagnostics

9.1 System Monitoring

A warning or an alarm is signaled by the relevant indicator

light on the device and indicated by an error code. If faults

occur during servo system operation, check:

•

The LEDs on the servo drive for general problems

relating to communication or device status.

•

The LEDs on the SAB for general problems with

communication, auxiliary supply, or STO voltage.

The error codes can be read using the ISD Toolbox

software, the LCP, or the PLC. The LCP only shows faults

relating to the device it is connected to.

A warning remains active until its cause is no longer

present, however the operation of the device may still be

continued. Warning messages may be critical, but are not

necessarily so. In the event of an alarm, the device goes to

Fault state.

Reset the alarm to resume operation. Reset alarms that are

not trip-locked using 1 of these 3 methods:

•

Using the [Reset] key on the LCP.

•

Using the PLC function block MC_Reset_ISD51x or

DD_Reset_SAB.

•

Using the ISD Toolbox.

If an alarm cannot be reset, the reason may be that the

cause has not been

rectied, or the alarm is trip-locked

(see Table 9.2) and (Table 9.5).

Alarms that are trip-locked

oer extra protection, meaning

that the supply voltage must be switched o before the

alarm can be reset. After being switched back on, the

device is no longer blocked and can be operated normally.

Use Wireshark

®

if there are network problems. Wireshark

®

is a free and open-source packet analyzer. It is used for

network troubleshooting, analysis, and software and

communications protocol development. It can be

downloaded via the Wireshark

®

webpage (wireshark.org).

NOTICE

If the fault cannot be eliminated by 1 of the measures

listed in Table 9.1 or Table 9.4, notify Danfoss Service.

Have the following information available to enable Danfoss

to provide help quickly and eectively:

•

Type number

•

Error code

•

Firmware version

•

System set-up (for example, number of servo

drives and lines).

9.2 Drive

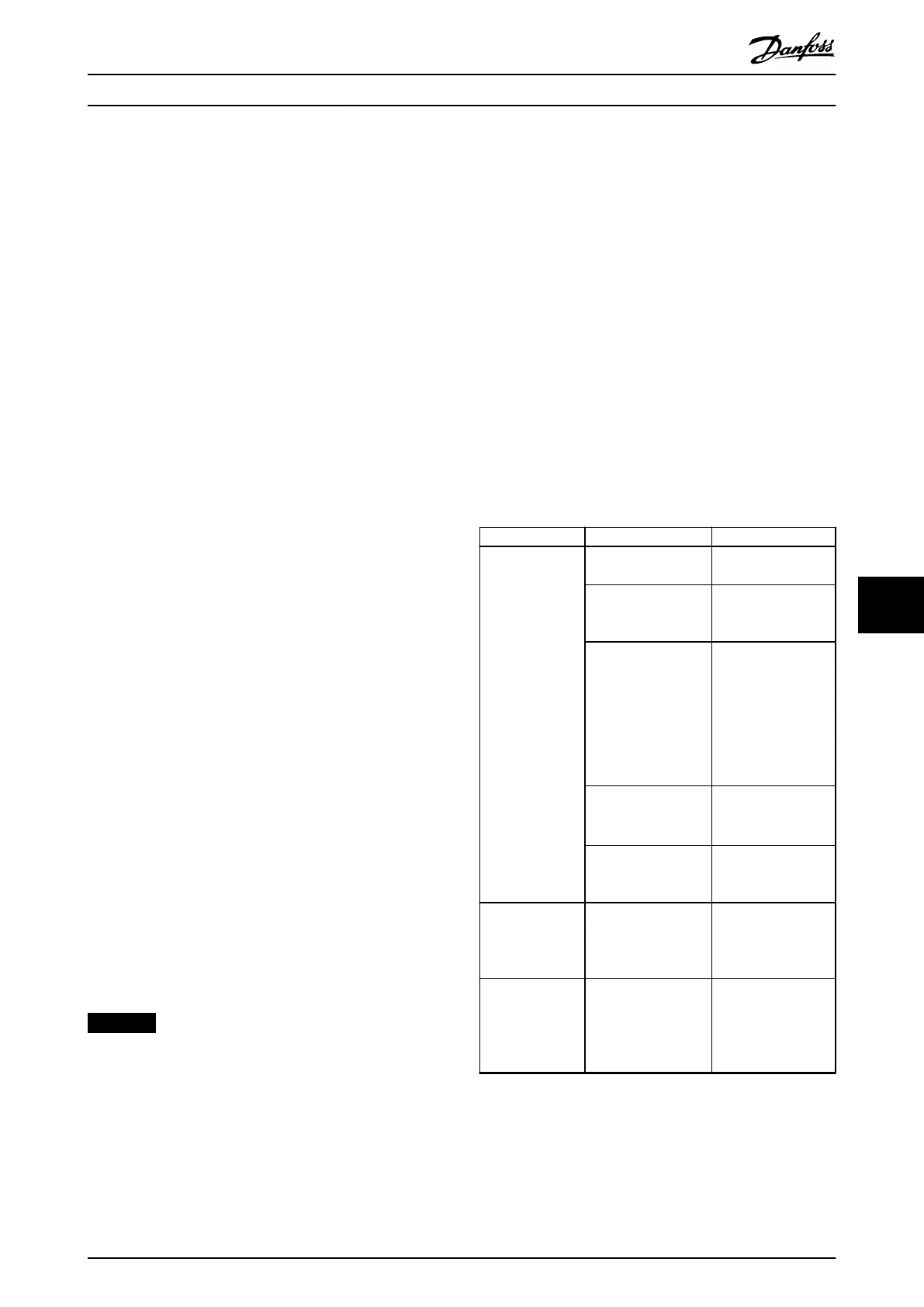

9.2.1 Troubleshooting

First use Table 9.1 to check the possible causes of the fault

and possible solutions. The error codes are listed in

chapter 9.2.2 Error Codes.

Fault Possible cause Possible solution

LCP display dark

or has no

function.

Missing input power. Check the input

power source.

Missing or open fuses

or circuit breaker

tripped.

Check the fuses and

circuit breaker.

No power to the LCP.

•

Check the LCP

cable for proper

connection or

damage.

•

Replace any faulty

LCP or connection

cables.

Incorrect contrast

setting.

Press [Status] +

[

▲

]/[

▼

] to adjust the

contrast.

Display is defective. Replace the faulty

LCP or connection

cable.

Servo drive

overheats (high

surface

temperature).

Excessive load. Check the torques.

Servo drive not

running.

No drive communi-

cation or drive in

error mode.

Check the eldbus

connection and the

status indicators

(LEDs) on the servo

drive.

Diagnostics Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 367

9 9

Loading...

Loading...