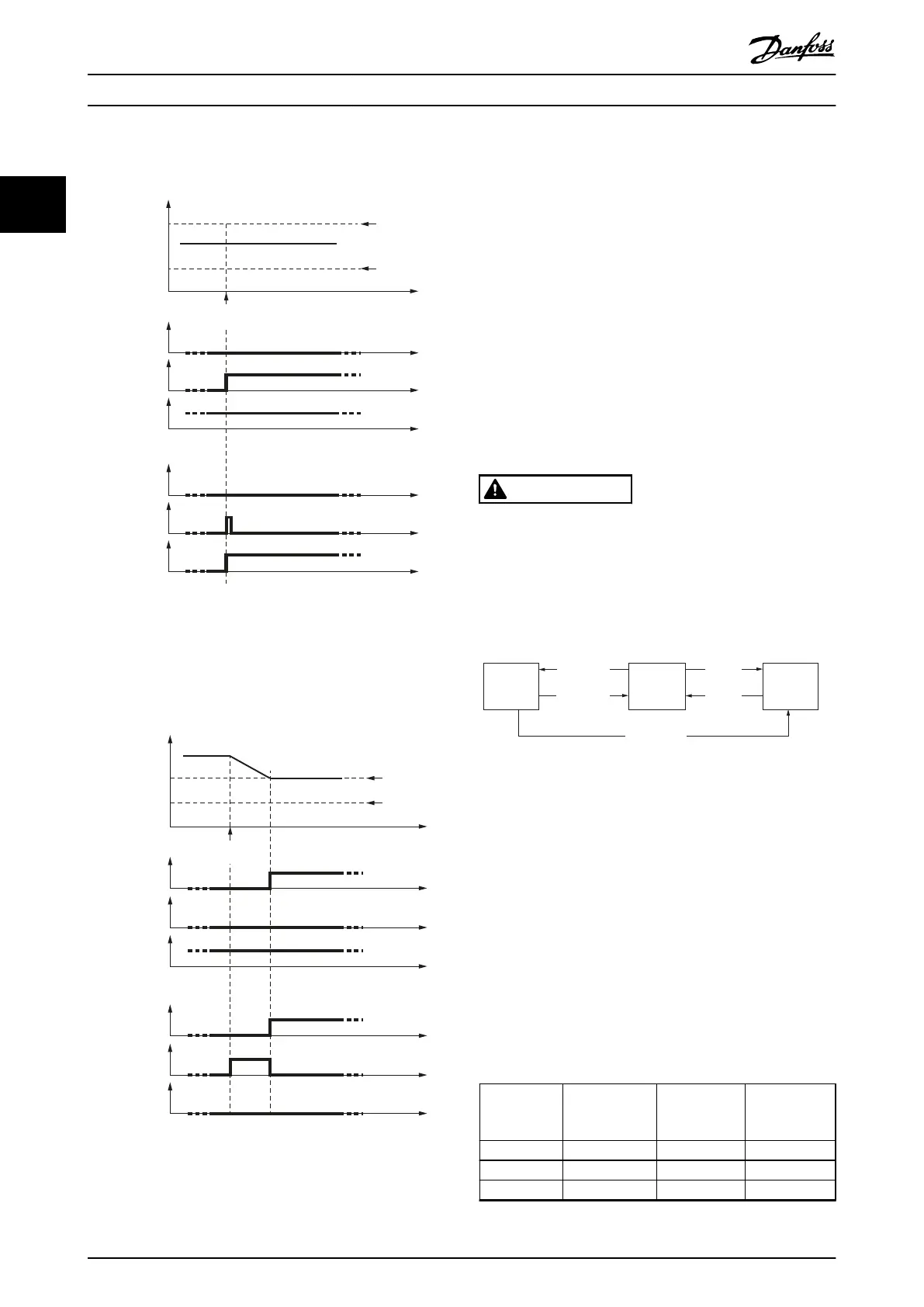

Target

reached

Position

Command

Error

Positive software

limit active

Done

PLC

Fieldbus

Busy

Error

Positioning

command

Target

position

Software

position limit

Time

130BF164.10

Illustration 2.8 Servo Drive is Outside the Valid Position Limit

and the Target Position is in the Wrong Direction

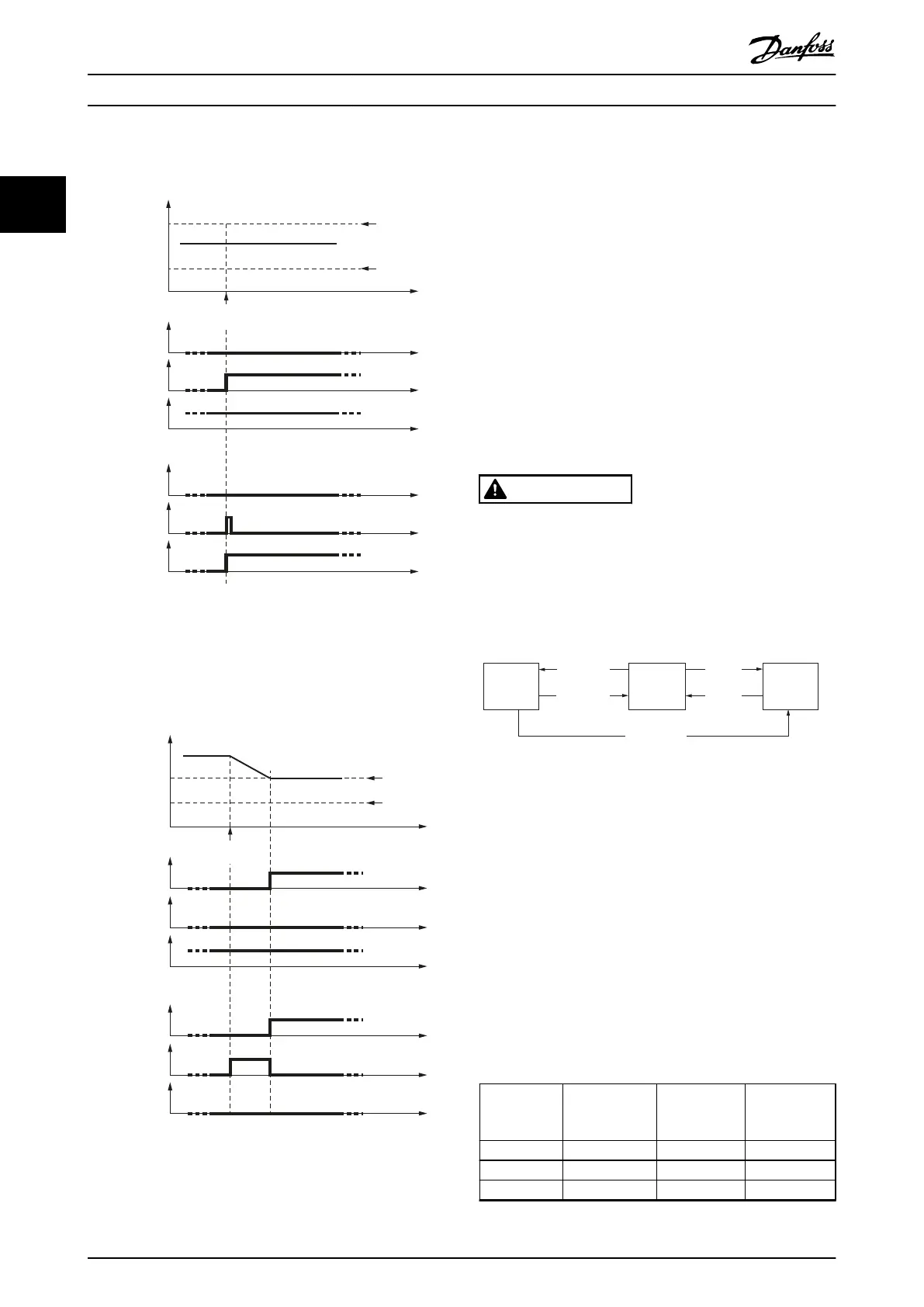

Target

reached

Position

Command

Error

Positive software

limit active

Done

PLC

Fieldbus

Busy

Error

Time

Target

position

Software

position limit

Positioning

command

130BF165.10

Illustration 2.9 Servo Drive is Outside the Valid Position Limit.

The Target Position is Still Not in a Valid Area, but is Nearer to

it than the Previous Position

2.3.5 Brake Handling

When the servo drive enters state Operation enabled, it

automatically lifts the brake. The servo drive reports the

new state after the brake is lifted.

When the servo drive leaves state Operation enabled, it

automatically releases the brake so that the axis cannot

sag down. The servo drive reports the new state after the

brake is unreleased.

The brake state can be overwritten using the digital output

object (see chapter 7.21.4 Parameter 16-66: Digital Outputs

(0x60FE)). This is only allowed in unpowered state. The

valid commands and the reactions are shown in

Illustration 2.10.

WARNING

UNINTENDED MOTION

Releasing the brake in an unpowered state may result in

unintended motion leading to death, serious injury,

damage to equipment, or other material damage.

•

Do not release the brake in an unpowered state.

Motor in

unpowered

state

Brake is open

Motor in

unpowered

state

Brake is closed

Motor is

energized

Brake is open

User command:

Close brake

Energize

motor

Unpower

motor

User command:

Open brake

Energize motor

Illustration 2.10 Valid Brake Commands and Reactions

It is not possible to have an energized motor with a closed

brake. For further information about the current state, see

chapter 7.22.8 Parameter 50-09: STO Voltage and Brake Status

(0x2007).

2.3.6 Control Loops

Servo motor control takes place using 3 cascaded control

loops (position controller, speed controller, and current

controller) with trajectory generators for position and

velocity. The control loops run synchronously with the

eldbus cycles. The cycle times shown in Table 2.3 are

possible with Ethernet POWERLINK

®

and EtherCAT

®

:

Fieldbus cycle

[µs]

Position control

cycle

[µs]

Speed control

cycle

[µs]

Current control

cycle

[µs]

400 200 200 100

500 250 250 125

800 200 200 100

Servo Drive Operation

VLT

®

Integrated Servo Drive ISD

®

510 System

24 Danfoss A/S © 01/2017 All rights reserved. MG36D102

22

Loading...

Loading...