Fieldbus cycle

[µs]

Position control

cycle

[µs]

Speed control

cycle

[µs]

Current control

cycle

[µs]

1000 250 250 125

Table 2.3 Ethernet POWERLINK

®

and EtherCAT

®

Cycle Times

The used cycle times can be read using object 0x201D (see

chapter 7.6.1 Parameter 51-07 to 51-09: Used Task Cycle

Times (0x201D)). The values are given in microseconds.

There are 2 control parameter sets in the servo drive,

however only 1 of them can be active at any time. Use bit

15 (cs) in the Controlword to switch from 1 set to the other.

Linear blending occurs from the parameter of the currently

active set to the new one. The blending time is dened in

object 0x201B (see chapter 7.6.2 Parameter 51-01: Control

Parameter Blending Time (0x201B)).

No blending takes place when writing to a value of the

currently active control parameter set. The new value is

used immediately, which could cause a jerk on the shaft.

Blending is used when updating a whole set of parameters

at the same time (for example, when activating CAM mode,

which uses its own sets of control parameters).

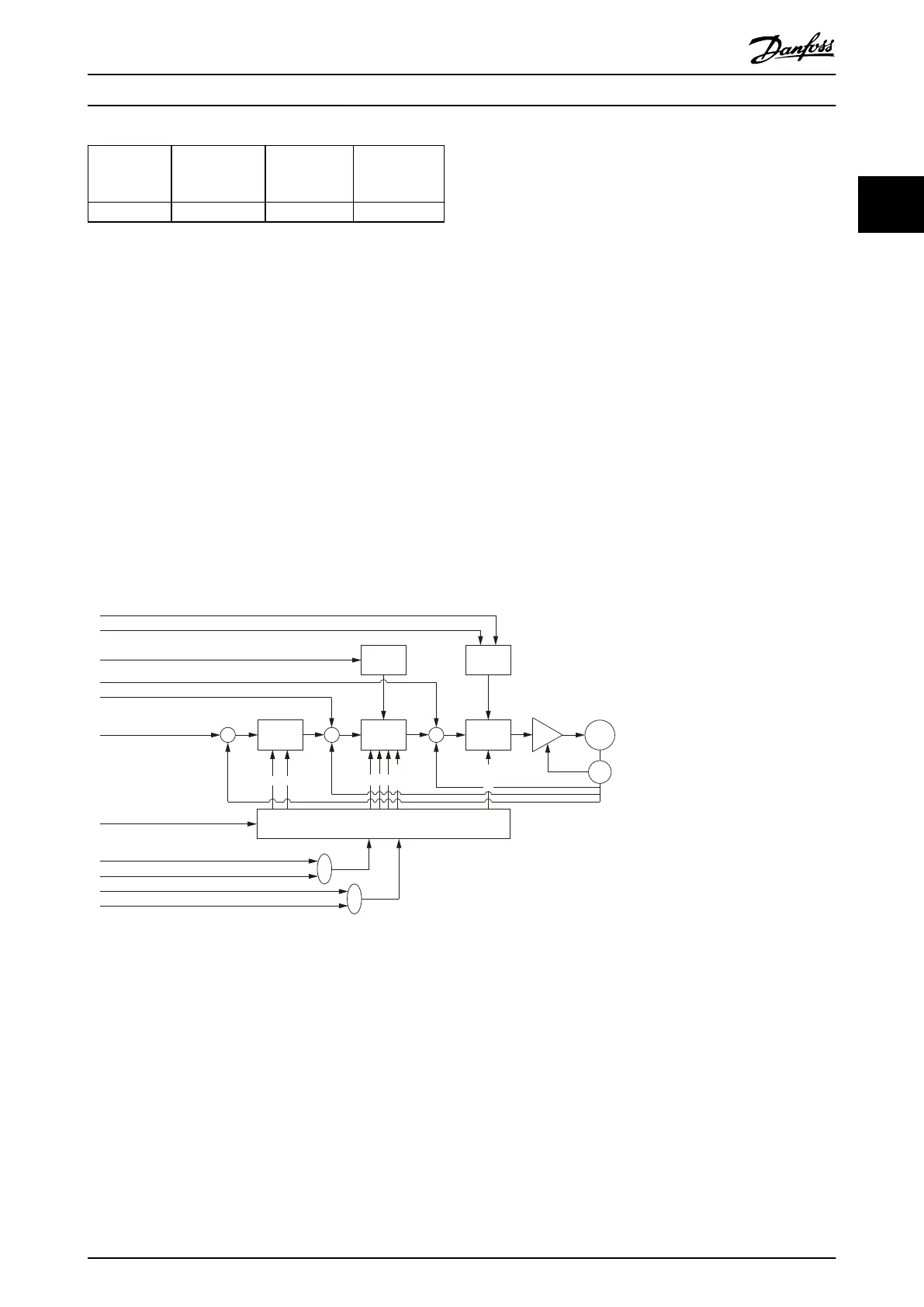

2.3.6.1 Position Controller

The controller uses PD control. The D constant is the derivative time constant. The controller provides 2 sets of control

parameters that can be switched during operation (see chapter 7.7.8 Parameters 51-02, 52-04, and 52-49: Application Settings

(0x2016) and chapter 7.6.4.2 Parameters 51-26 and 51-27: Position Controller Parameters 2 (0x2015)).

Both sets are available as read-write objects in the object dictionary. Use a manufacturer-specic bit in the Controlword to

switch between the 2 sets of parameters.

Limit

function

Limit

function

Torque

control

Velocity

control

Position

control

Selector

Application torque limit (0x2053)

Max torque (0x6072)

Max motor speed (0x6080)

Feed forward torque

Feed forward velocity

Position demand

Internal value (0x60FC)

Controlword (0x6040)

Position controller parameters (0x2013)

Speed controller parameters (0x2012)

Position controller parameters 2 (0x2015)

Speed controller parameters 2 (0x2014)

+

+

+

+

– – –

+

P D

P D

Notch

Inertia

M

S

Illustration 2.11 Position Control Loop

Servo Drive Operation Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 25

2 2

Loading...

Loading...