Attribute

Mandatory/

optional

(+default

value)

Value range/

allowed values

Description

input M 1/2 Selects if the

1

st

or the 2

nd

digital input

counter is

aected.

Table 2.43 Attributes for stopCounter

The counter values can be read from the object 0x3860

(see chapter 7.14.17 Parameter: Digital Input Counters

(0x3860)). The values are read/write for manually modifying

the counters.

Action: Set Follow Segment

Instructs the servo drive to change the used succeeding

segment of a node. It is only possible to select a segment

ID that has this node ID

dened as preceding node. This

change is preserved over the guide value cycles, so no

automatic switching back takes place.

<setFollowSegment nodeID="1" segID="2"/>

Attribute

Mandatory/

optional

(+default

value)

Value range/

allowed values

Description

nodeID M An existing

node ID.

The mode ID

to get another

following

segment.

When using a

non-existing

nodeID, a

notication

from the axis is

sent.

segID M An existing

segment ID.

The segment

ID that will be

processed after

the specied

node. When

using a non-

existing segID,

a notication

from the axis is

sent.

Table 2.44 Attributes for setFollowSegment

Exit conditions

The following exit conditions are used to monitor several

variables. The axis proceeds with the next segment as soon

as the condition is met. Exit conditions can only be dened

for EventSegments.

An exit condition is described with a surrounding element

to dene an exitID which is used for referencing inside the

CAM prole. This exitID must be unique across all dened

exit conditions. Inside this exit element, there can be 1 or

more subelements. Available exit conditions are listed in the

following sub-chapters.

<exit exitID="0">

… specic exit condition(s) with corresponding attributes

<exit>

Exit: Rectangle Mark Detection

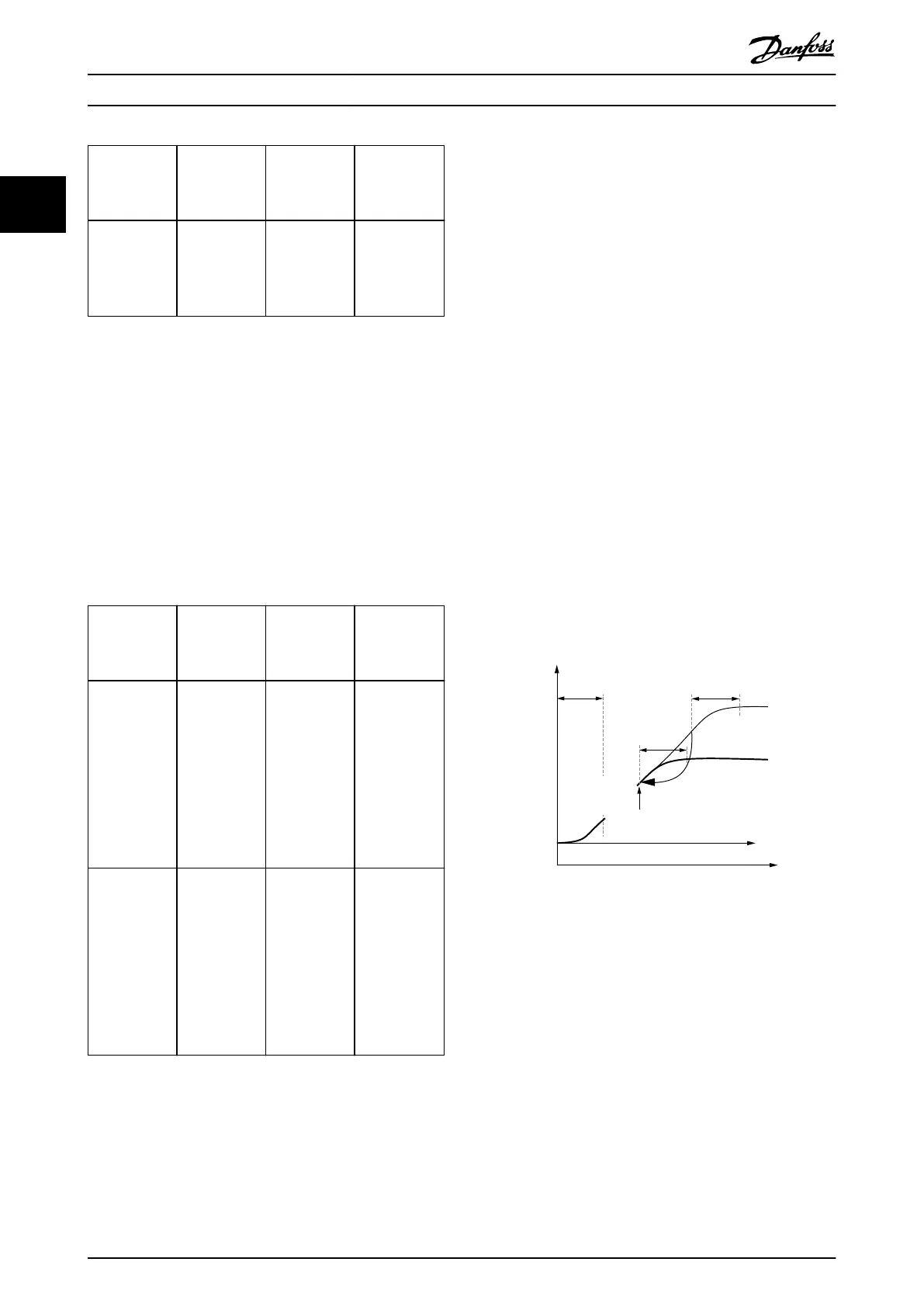

This exit condition is used to start the search for a

rectangle mark, using the sensor interface. This exit

condition is used for alignment, depending on a sensor

signal. When using this exit condition, the axis waits for a

rectangle input on the sensor interface with a length

between the specied minimum and maximum.

When using an analog sensor, a threshold for the height of

the impulse must be dened. Positive and negative

impulses can be processed. This equates to light and dark

marks with optical sensors. The axis proceeds with the next

segment as soon as the impulse is found or the maximum

duration of the segment is reached.

If the mark has been found and the following segment is a

braking segment (TimePoly which leads to a standstill), the

servo drive always stops at the same distance to the mark.

130BF260.10

Accelerating

phase

Rotor angle

Decelerating

phase

Decelerating

phase

Guide value

Time

Mark

found

Constant plate speed

during search for

mark

Illustration 2.113 Behavior when Mark was Found

The time at which the mark is found depends on the

position of the mark. The black line shows an example for

the case that the mark is found right at the point in time

that is marked with the black arrow.

The duration of the segment determines the latest point in

time when the search is aborted. If the mark is found

before this duration is over, the axis proceeds with the

following segment immediately after the mark is found.

Proceeding to the next segment always takes place in

relation to the middle of the impulse. To make this

possible, the point in time for proceeding depends on the

parameterized maximal length of the mark.

<rectMark input="1" mode="analogue" threshold="50"

minLength="300" maxLength="400"/>

Servo Drive Operation

VLT

®

Integrated Servo Drive ISD

®

510 System

72 Danfoss A/S © 01/2017 All rights reserved. MG36D102

22

Loading...

Loading...