11 Troubleshooting

Failure during regeneration

Page

11 - 18

MB-20-G/MB-200G-W_MB-LABmaster_MB-200 MOD_TP700

Operating Manual - V5.0 - 04/2018 - STD

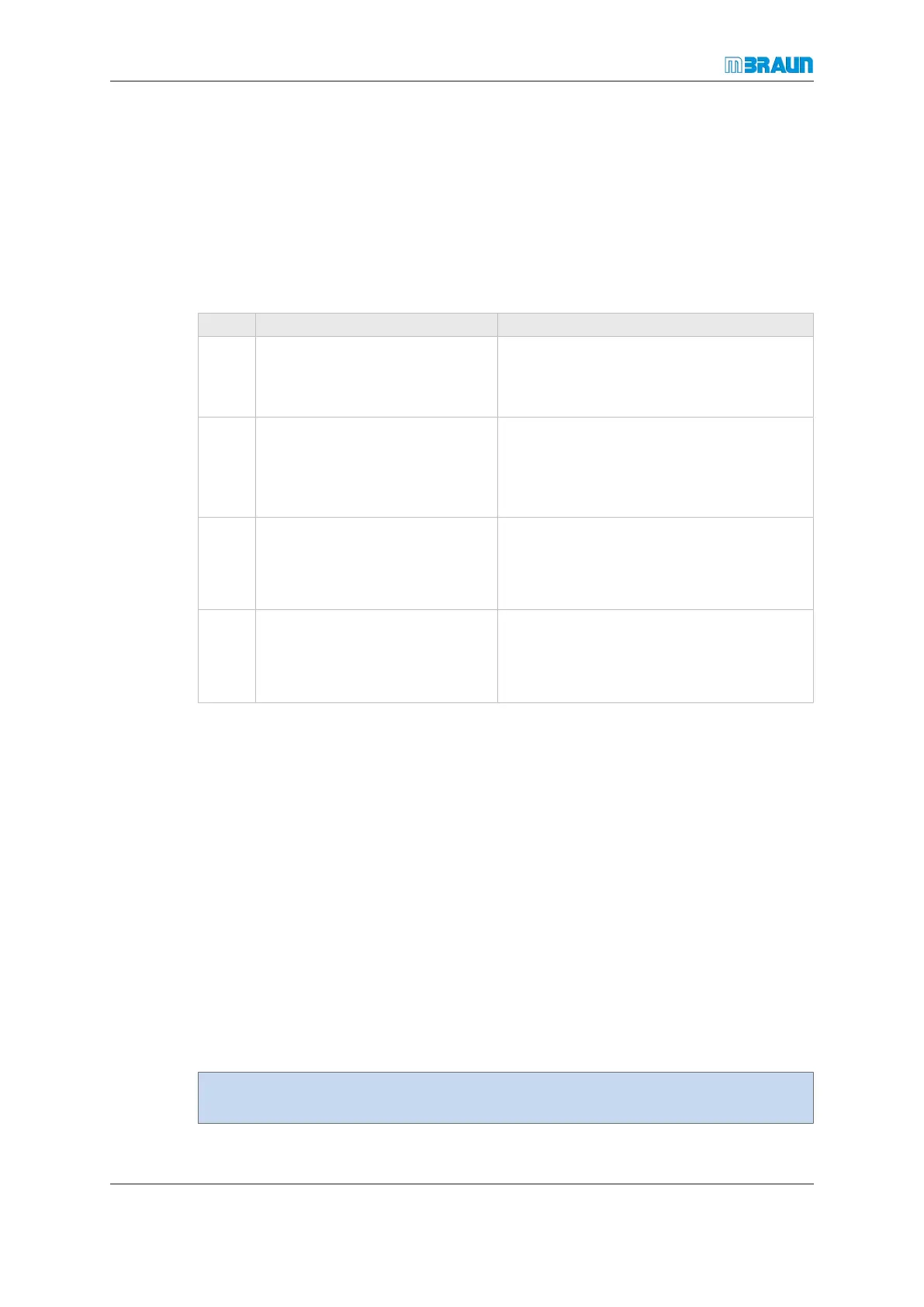

11.5 Failure during regeneration

For information on the regular regeneration sequence, refer to section Regeneration se-

quence [}7 - 17].

11.5.1 Cancellation or power failure

The following table indicates the possible actions after cancelling a regeneration process

or after a power failure occurred during a regeneration process.

Case Interruption To do

1 Failure after regeneration gas

check

► Skip ahead to step8.

ð Evacuation and refill cycles are

shortened (total 20min).

2 Cancellation during step3

through 7

► Skip ahead to step8.

ð Evacuation and refill cycles remain (en-

sure sufficient reactor cooling regard-

less of the elapsed heating time).

3 Power failure during step3

through 7

Once power is restored, regeneration con-

tinues from step 3. This means that the en-

tire regeneration heat-up phase is re-

peated.

4 Power failure during step5

through 16

Once power is restored, regeneration con-

tinues precisely where it was interrupted at

exactly the point of interruption (there is no

return to the start of the current step).

11.5.2 Regeneration of an LMF

The regeneration programme can only be cancelled during step1 (without the "Cancel

yes / no" security question).

After cancellation, the sequence skips ahead the last step, since no evacuation / refill

cycles are necessary (for N

2

).

11.6 Leak test

A leak test must be performed on the system:

¡ After recommissioning

¡ After unexplained increase of the O

2

content in the glovebox or enclosure

¡ If an unexplained pressure increase/drop in the glovebox or enclosure occurs

A leak test can be performed by MBRAUN Service.

MBRAUN offers training to qualify personnel to perform leak tests.

► Contact MBRAUN Service for assistance.

Loading...

Loading...