12 Maintenance

Maintenance works

Page

12 - 12

MB-20-G/MB-200G-W_MB-LABmaster_MB-200 MOD_TP700

Operating Manual - V5.0 - 04/2018 - STD

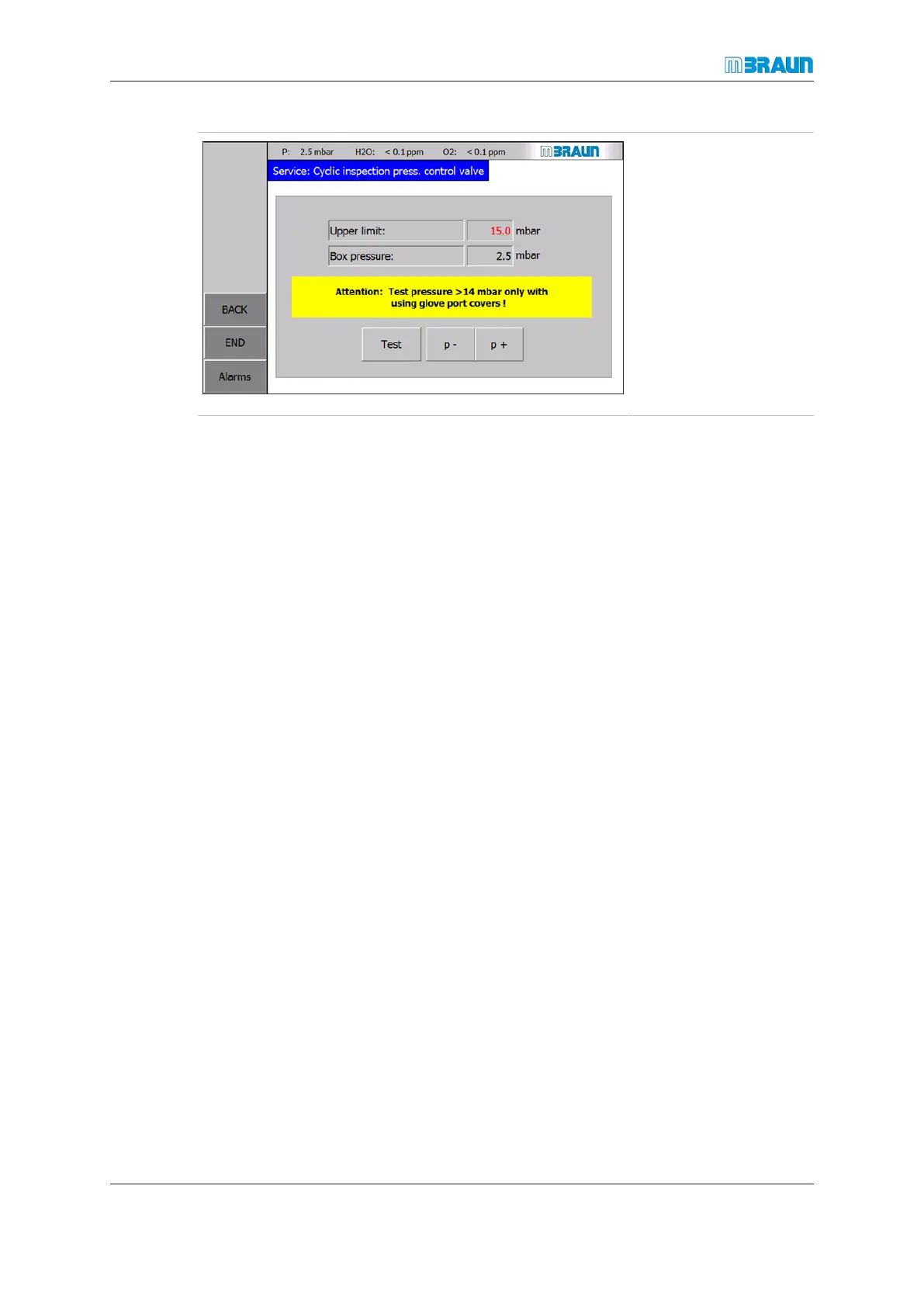

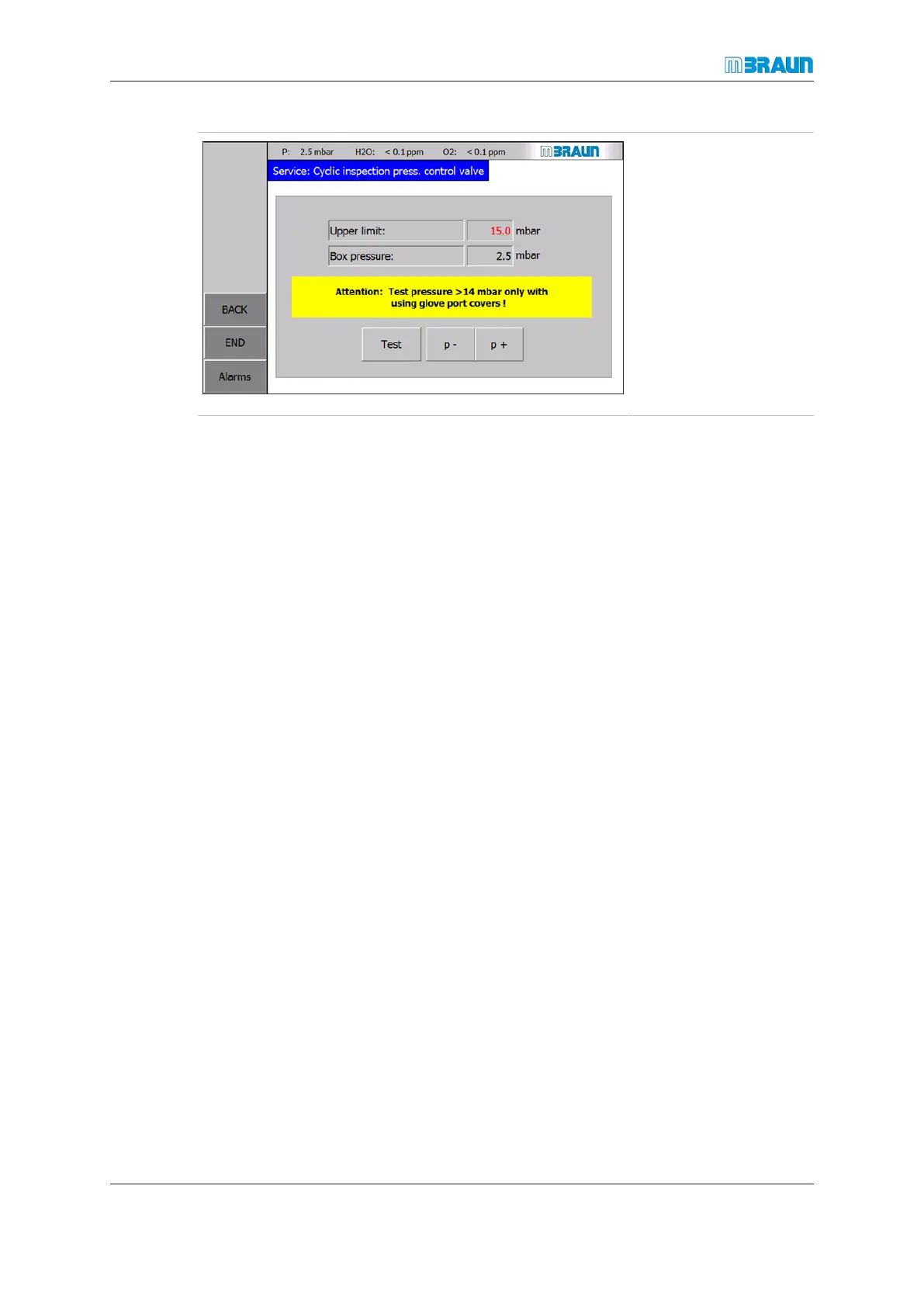

► Set the test pressure

using the “p +” and

“p -“ buttons.

► Call a second person

for assistance. While

one person starts the

test, the second per-

son checks the func-

tion of the valve(s)

by putting a hand

over the exhaust

(“hand test”).

► Touch the “Test” but-

ton to start the test.

12.6.2 Gloves

Preparation

Basic rules

► Regard the basic rules for inspection in chapter Overview [}8 - 1].

► Always keep a set of gloves, O-rings and gloveport covers ready for an unplanned

change (refer to Spare parts).

► Ensure that the correct glove size and type of glove is chosen e.g. left or right hand,

or ambidextrous.

► Do not seal at least one gloveport feedthrough!

► Recommendation: Train the glove change regularly so that in case of error during

ongoing operation you can replace the gloves quickly and safely.

► If sensitive processes take place or those that endanger health or the environment:

Additional equipment for redundant safety is required! Refer to chapter Safety. Spe-

cify the procedure in your operation-specific standard flow plan.

► Keep the appropriate personal protective equipment (PPE) at hand.

Regular care

Only outside the glovebox/enclosure (user's side):

► Sprinkle the gloves’ inside with a little talcum powder.

► Do not use any talcum powder inside the box, on the gloves’ outside or in clean-

rooms!

Replacing gloves

The process differs depending on the type of processes and process materials used.

MBRAUN recommends the following application types:

There are special instructions for gloves and gloveport feedthroughs with different meth-

ods of changing gloves depending on the form of the gloves (e.g. round or oval – see

special chapters).

Loading...

Loading...