2 Inert gas technology

Functional description

Page

2 - 22

MB-20-G/MB-200G-W_MB-LABmaster_MB-200 MOD_TP700

Operating Manual - V5.0 - 04/2018 - STD

4a Intervention by the automatic box pressure regulation: gas withdrawal is started

4b Intervention by the automatic box pressure regulation: gas inlet is started

2.3.6 Vacuum antechamber

Antechamber cycle

After material is moved from the outside to the inside of the antechamber, the antecham-

ber must be evacuated to deaerate the ambient air in the material. The evacuation is

stopped at a target vacuum level. The refill valve must then be opened to refill the ante-

chamber with working gas from the glovebox/enclosure either to an upper vacuum level

(if the process is Siemens PLC-controlled) or to nearly atmospheric pressure (if manually

controlled).

To obtain a highly pure atmosphere in the glovebox/enclosure, this process has to be re-

peated several times. Repeated evacuation and refilling increases the purity of the ante-

chamber atmosphere to approximately the level of the atmosphere.

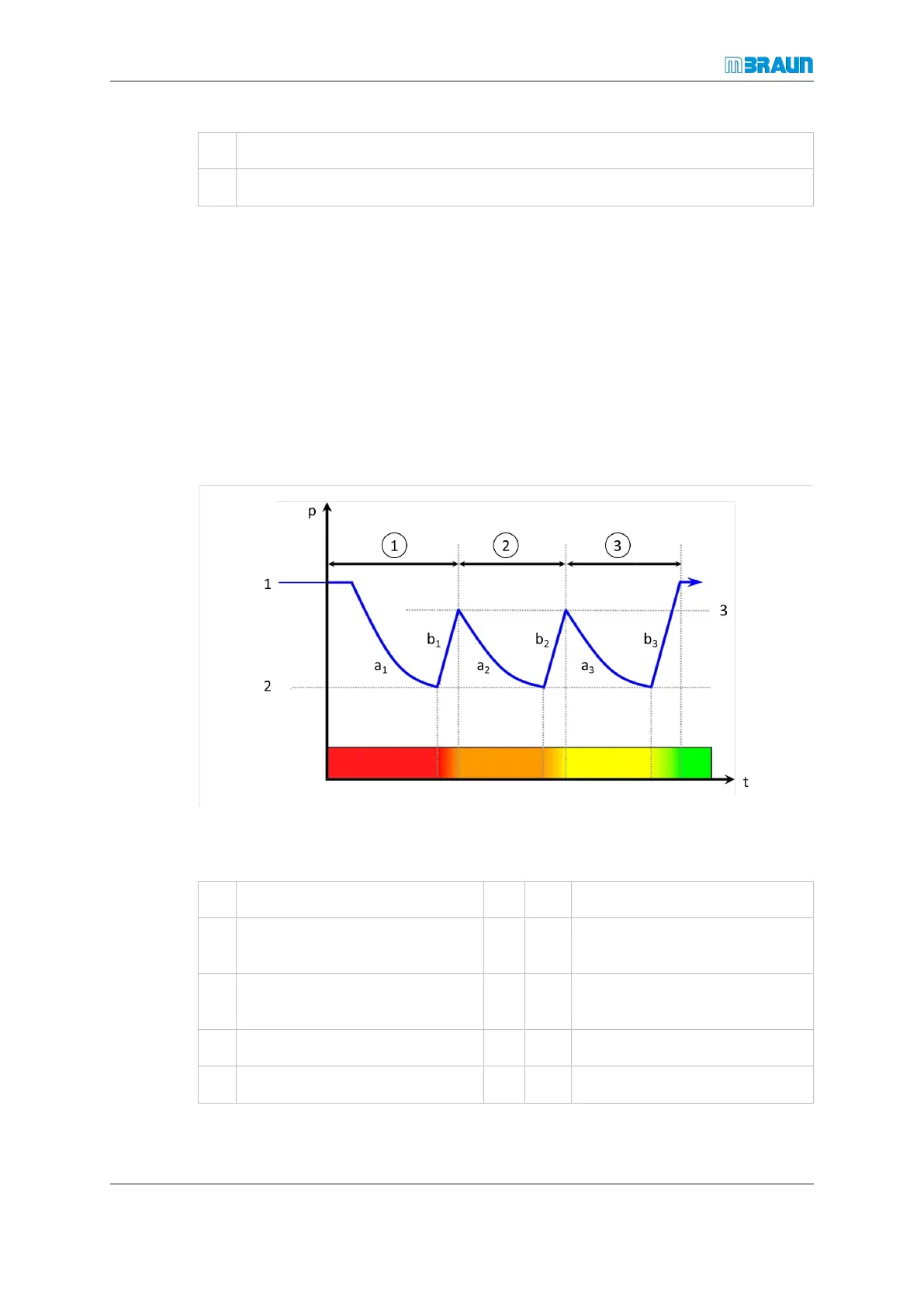

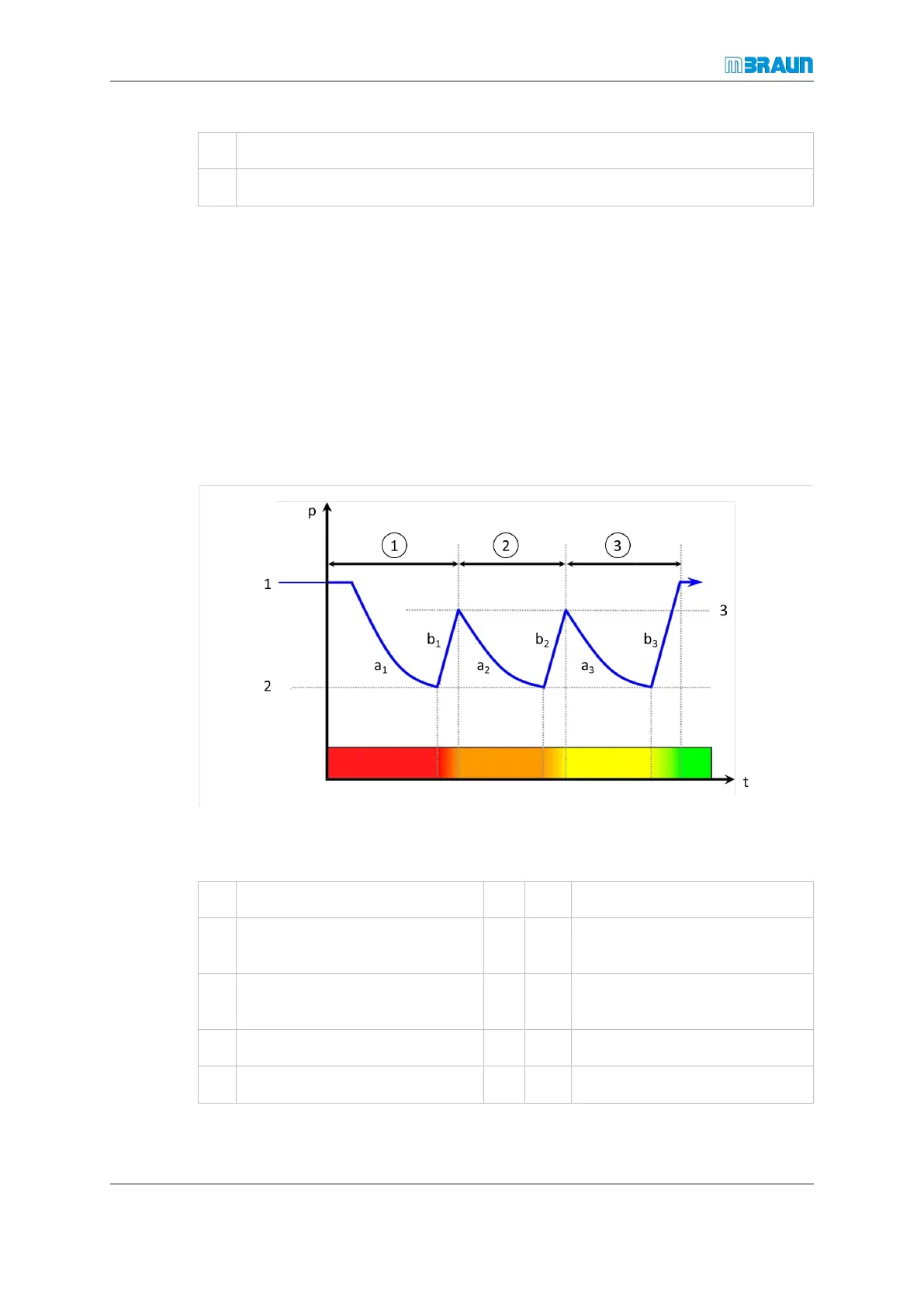

Refer to figure above: transition from initial purity of the antechamber atmosphere (depic-

ted in red) to the target purity of the inert gas atmosphere in the glovebox/enclosure (de-

picted in green).

1 Atmospheric pressure ① Evacuate and refill cycle 1

2 Target vacuum of the antecham-

ber cycle process

② Evacuate and refill cycle 2

3 Pressure inside the glovebox/en-

closure

③ Evacuate and refill cycle 3

a

n

Evacuation cycle n p Internal antechamber pressure

b

n

Refill cycle n t Time

Loading...

Loading...