3 Safety

Process materials

MB-20-G/MB-200G-W_MB-LABmaster_MB-200 MOD_TP700

Operating Manual - V5.0 - 04/2018 - STD

Page

3 - 9

If flammable gases are released inside the box and the resulting mixture has a concentra-

tion level which would allow ignition in contact with air, a secure zone shift must be avail-

able inside the box. Safe box operation must be maintained by keeping the oxygen con-

centration < 2% in the box atmosphere even in case of malfunctions.

The following system modifications and safety features are required:

Safety measure step MBRAUN item no.

1 - 6 All of MB-HC-II and MB-HC-III

7 ¡ Safe oxygen measurement with self-check and

secure box-purge feature in case of a failure.

¡ An upgrade of all pressure sensors to the "EX

model" version.

¡ An upgrade of the glove feedthroughs to elec-

trostatic dissipative types.

1507306

3.8.3 Examples of a rough classification

The following table shows how substances can be divided roughly into hazard classes,

using exposure limits and H- and P-signs. The table does not take into account the quant-

ity of substances in the system, the material’s condition, and the contact time with a re-

active partner.

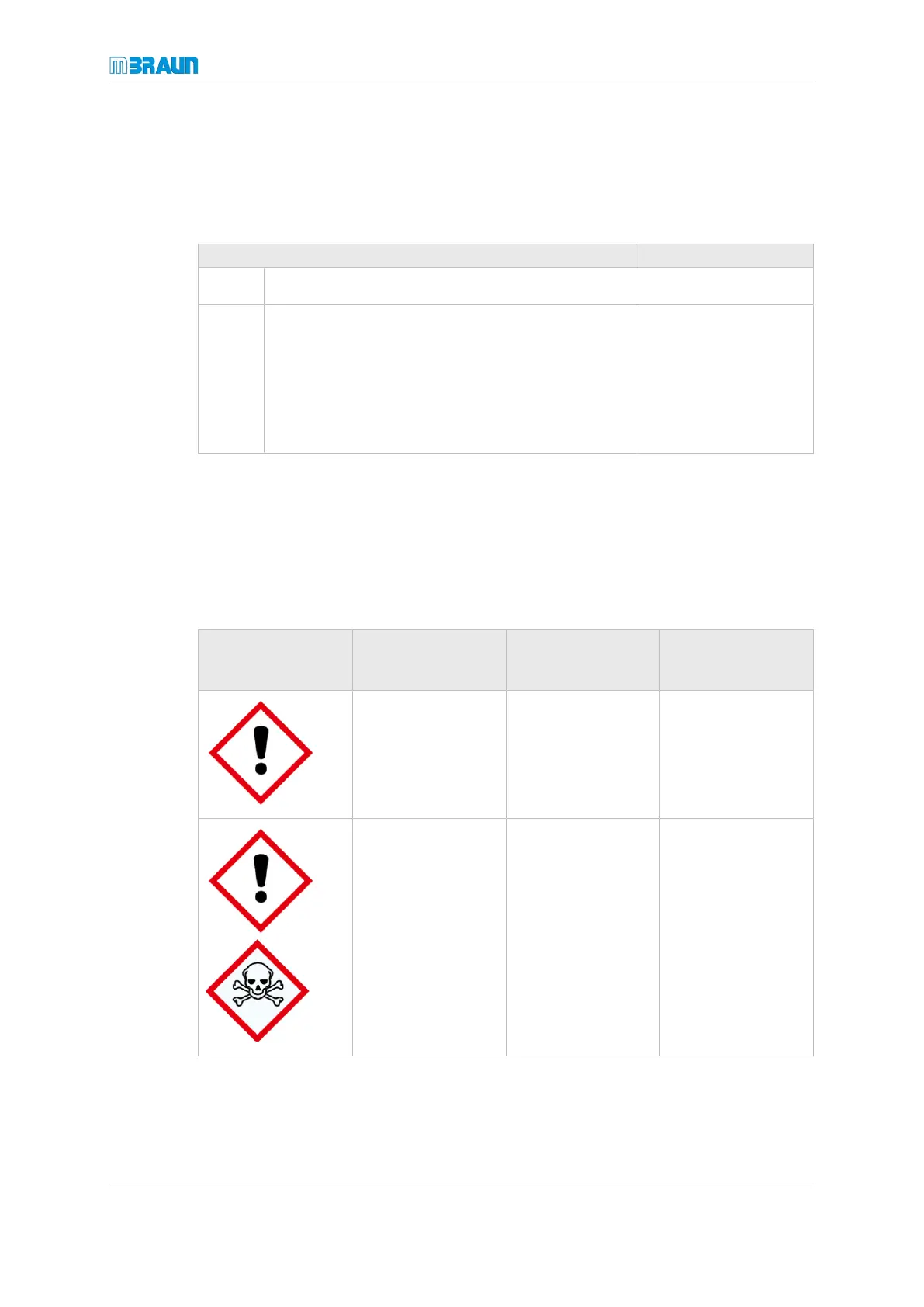

Overview of hazard classes and acceptable limits of exposure

1

Pictogram Class Acceptable limits of

exposure (µg/m

3

dust / ppm vapour)

Typical H-statements

Hazard class MB-

HC-0

General ventilation

1,000 – 10,000 µg/

m

3

50 – 500 ppm

H319, H315, H317

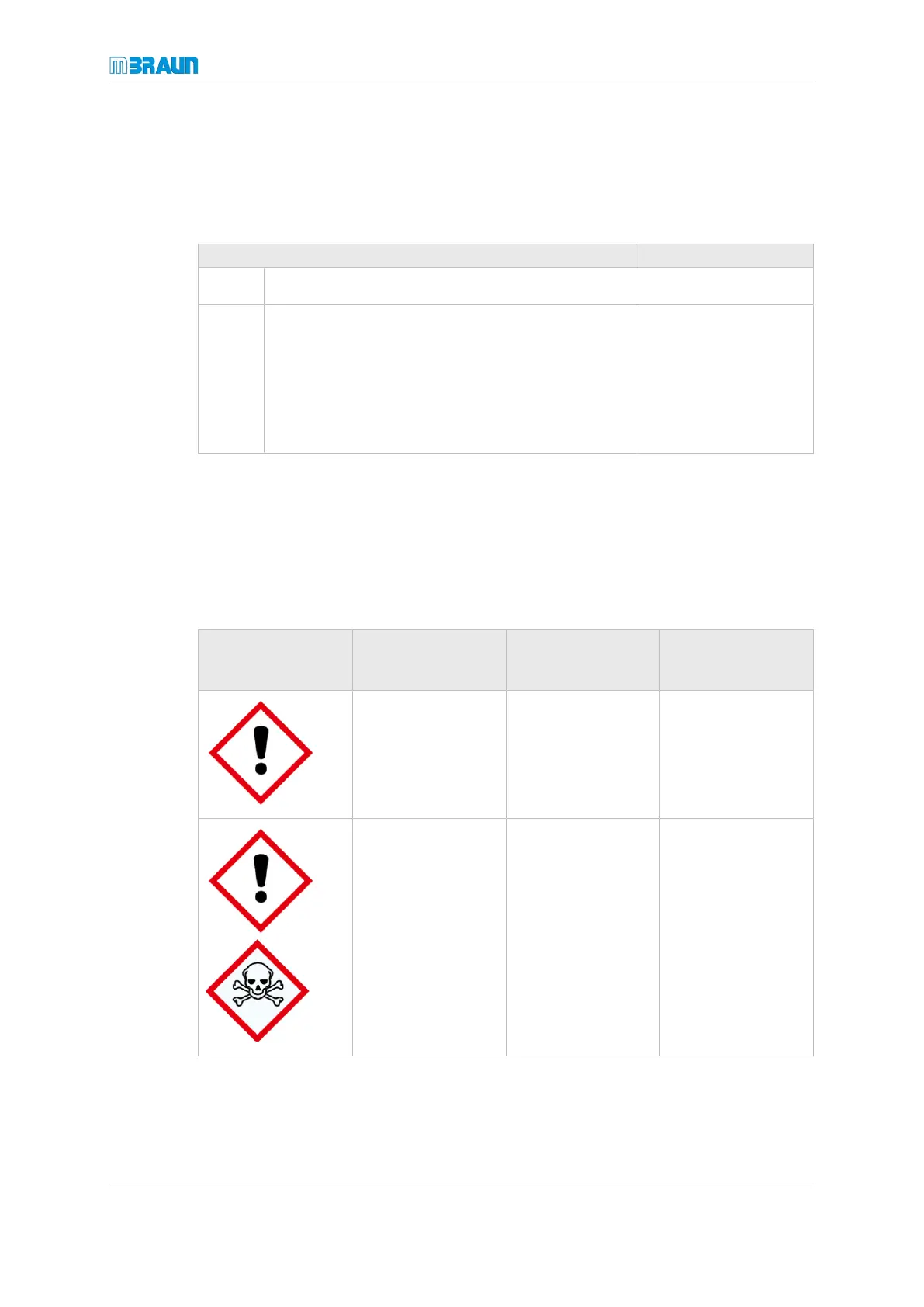

Hazard classMB-

HC-I

Low and "normal"

hazard

100 – 1,000 µg/ m

3

5 - 50 ppm

H332, H312, H302

(not in combination

with H317)

Loading...

Loading...