4 Transport, installation and commissioning

Commissioning

MB-20-G/MB-200G-W_MB-LABmaster_MB-200 MOD_TP700

Operating Manual - V5.0 - 04/2018 - STD

Page

4 - 31

4.3.2 Inertisation of the glovebox

Newly installed or used inert gas systems contain ambient air. Before circulation through

an activated, and regenerated reactor can be switched on, the ambient air needs to be

replaced by the working gas. Displacing the ambient air from the system is called purging

or inertisation.

The system must be purged down to a residual oxygen concentration of approximately

100 ppm using medium-purity inert gas.

An inert gas system should always be purged when the oxygen concentration in the

glovebox atmosphere exceeds 100 ppm (V). An automatic box purge feature is available

as an option.

Exceedingly high oxygen concentration values can occur for the following reasons:

¡ Initial system commissioning

¡ Service work

¡ Air influx due to faulty operation

¡ Air influx due to damage (leaks)

Purge gas consumption

The operator must ensure that sufficient purge gas is available for system commission-

ing.

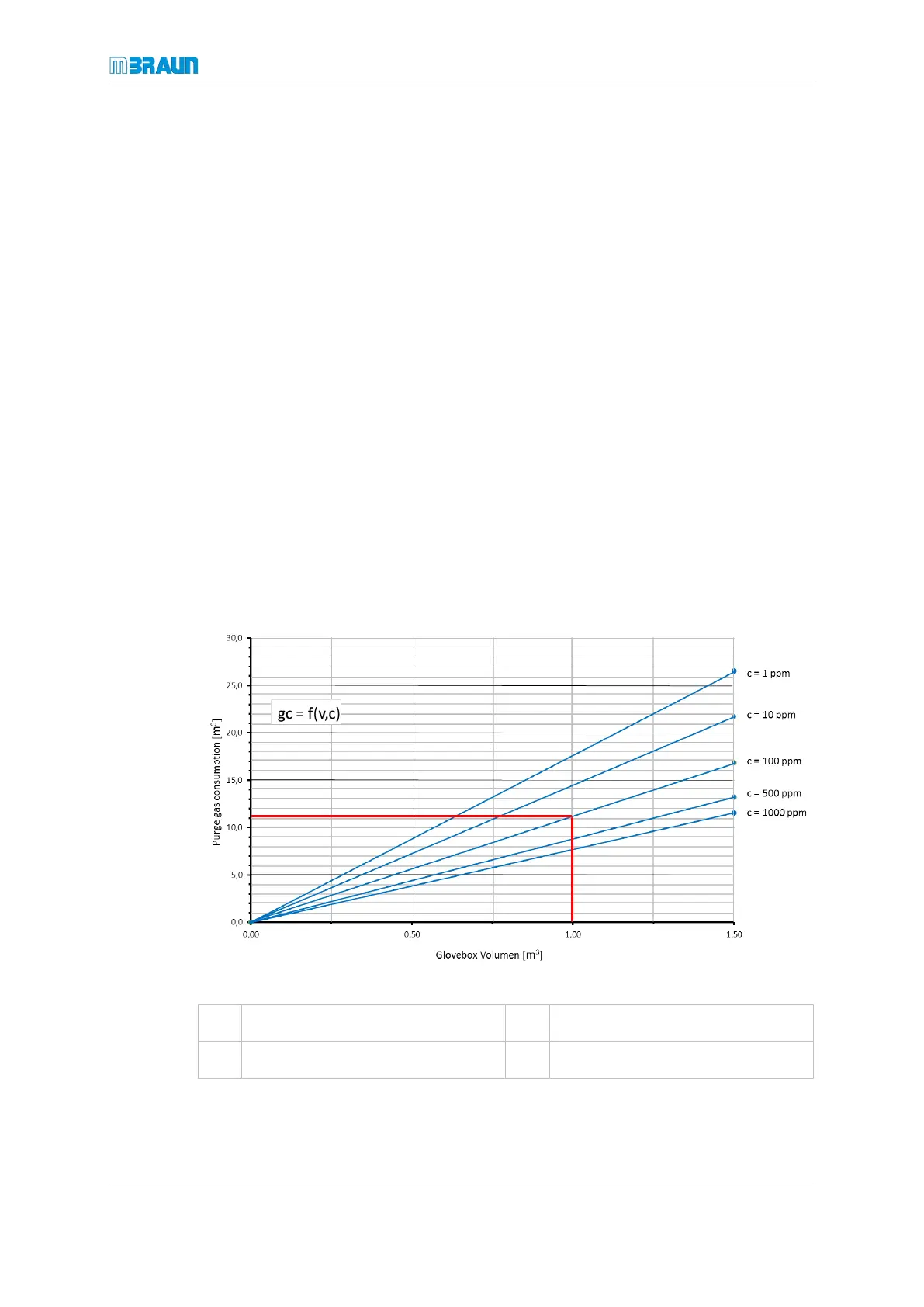

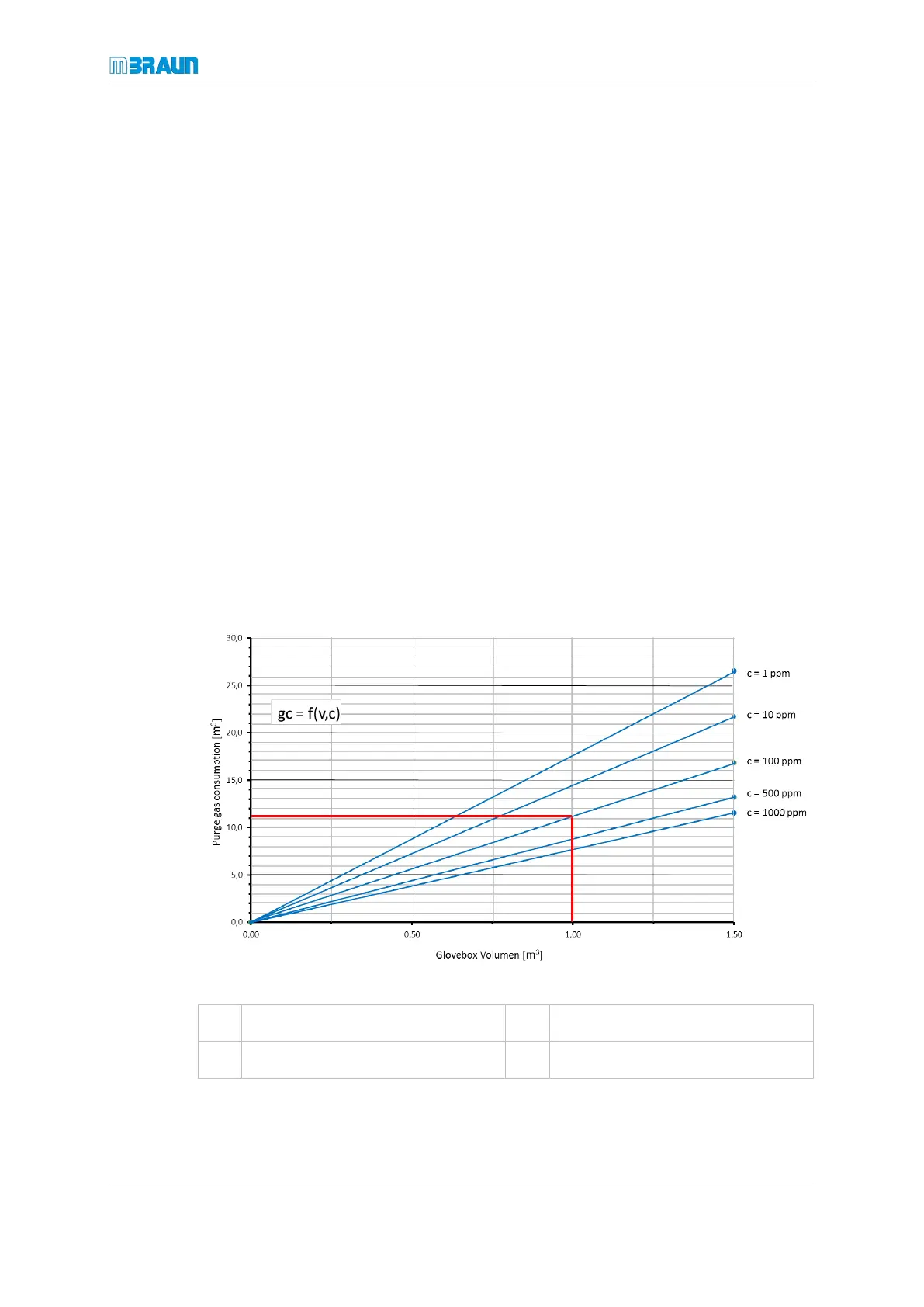

The figure below provides a guideline for estimating the amount of purge gas required.

gc Gas consumption c Gas purity

v Glovebox volume

According to the diagram above, if a purity (c) of 100 ppm (V) is requested, about 11.2 m

3

of purge gas is required per 1 m

3

of glovebox volume.

Loading...

Loading...