4 Transport, installation and commissioning

Installation

Page

4 - 12

MB-20-G/MB-200G-W_MB-LABmaster_MB-200 MOD_TP700

Operating Manual - V5.0 - 04/2018 - STD

3b Gas purifier 3c Recirculation chiller (optional supplied by

MBRAUN)

3d Vacuum pump Clear room volume: occupied with ambi-

ent air, in case of a failure with inert gas

4.2.2 Preparing the site

Example: Combination with a MBRAUN glovebox

Site selection for an MBRAUN system or any part of a multi-unit system should be carried

out by applying the following guidelines:

¡ All media connections required by the system must be available (refer to Media sup-

ply overview [}4 - 14]).

¡ The site requirements have been met (refer to On-site conditions [}2 - 28]).

¡ There is enough free space available:

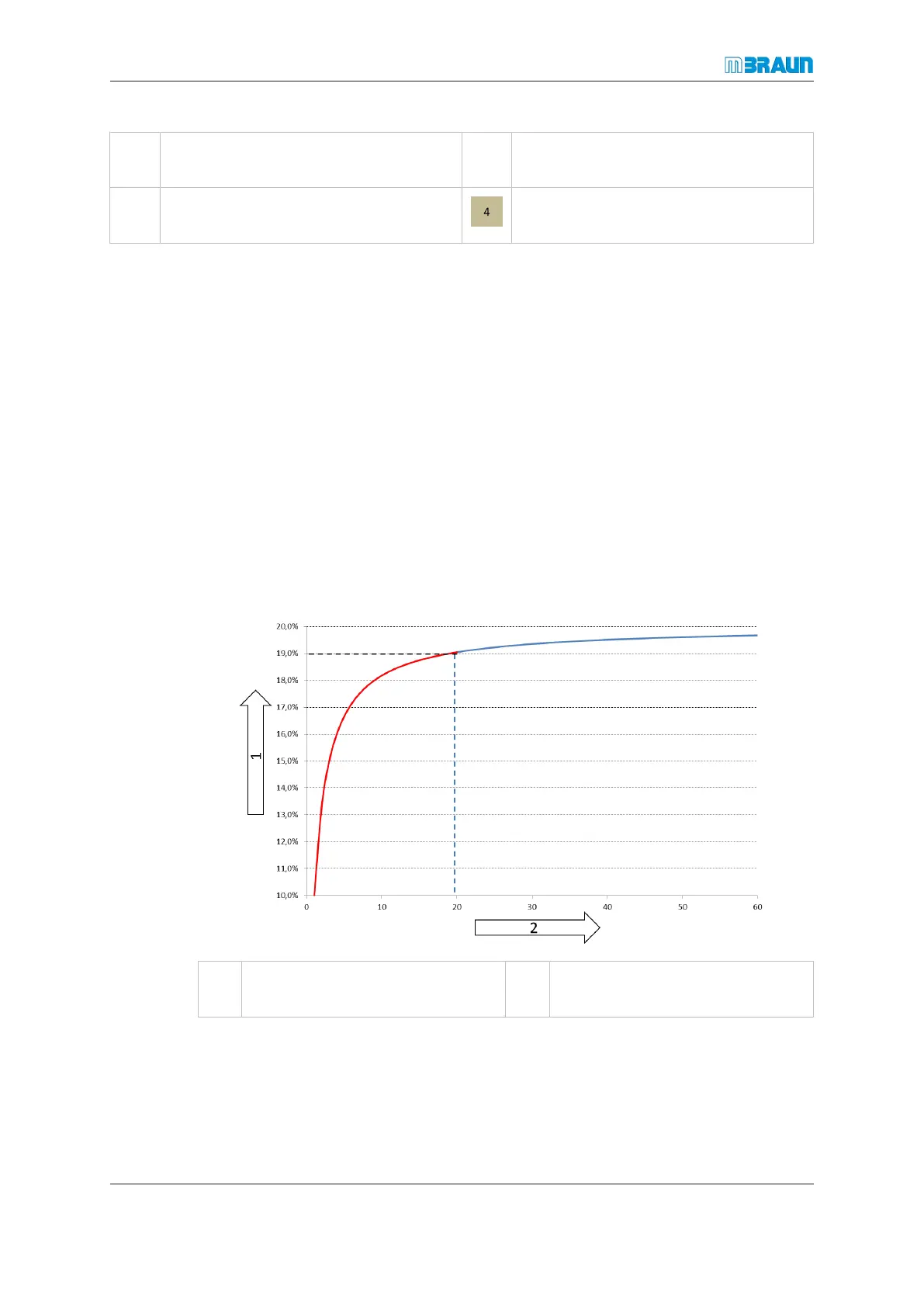

¡ The safe room volume in case of a glove tear is determined using the figure be-

low. This figure indicates, as a multiple of the glovebox volume, the minimum

clear room volume (of a closed room) if in case of a glove tear all working gas es-

capes. Hereby the O

2

concentration in the room does not fall below 19%.

The minimum O

2

concentration (refer to Preparing the site [}4 - 13]) is 18%, re-

quiring a minimum clear room volume of 10 times the glovebox volume.

1 O

2

concentration in the room after

loss of glovebox‘s working gas

2 Ratio (room volume / box volume)

The figure above is void for an automatic or a manual glovebox purge.

¡ In case of a manual glovebox purge, with 50l pressurized vessel (200 bar) as the

gas source, the required minimum room size is 200 m

3

if in case of a leakage the

O

2

concentration in the room should not fall below 19%. To keep the minimum O

2

concentration requires a minimum clear volume of 100 m

3

.

Loading...

Loading...