2 Inert gas technology

Components

Page

2 - 10

MB-20-G/MB-200G-W_MB-LABmaster_MB-200 MOD_TP700

Operating Manual - V5.0 - 04/2018 - STD

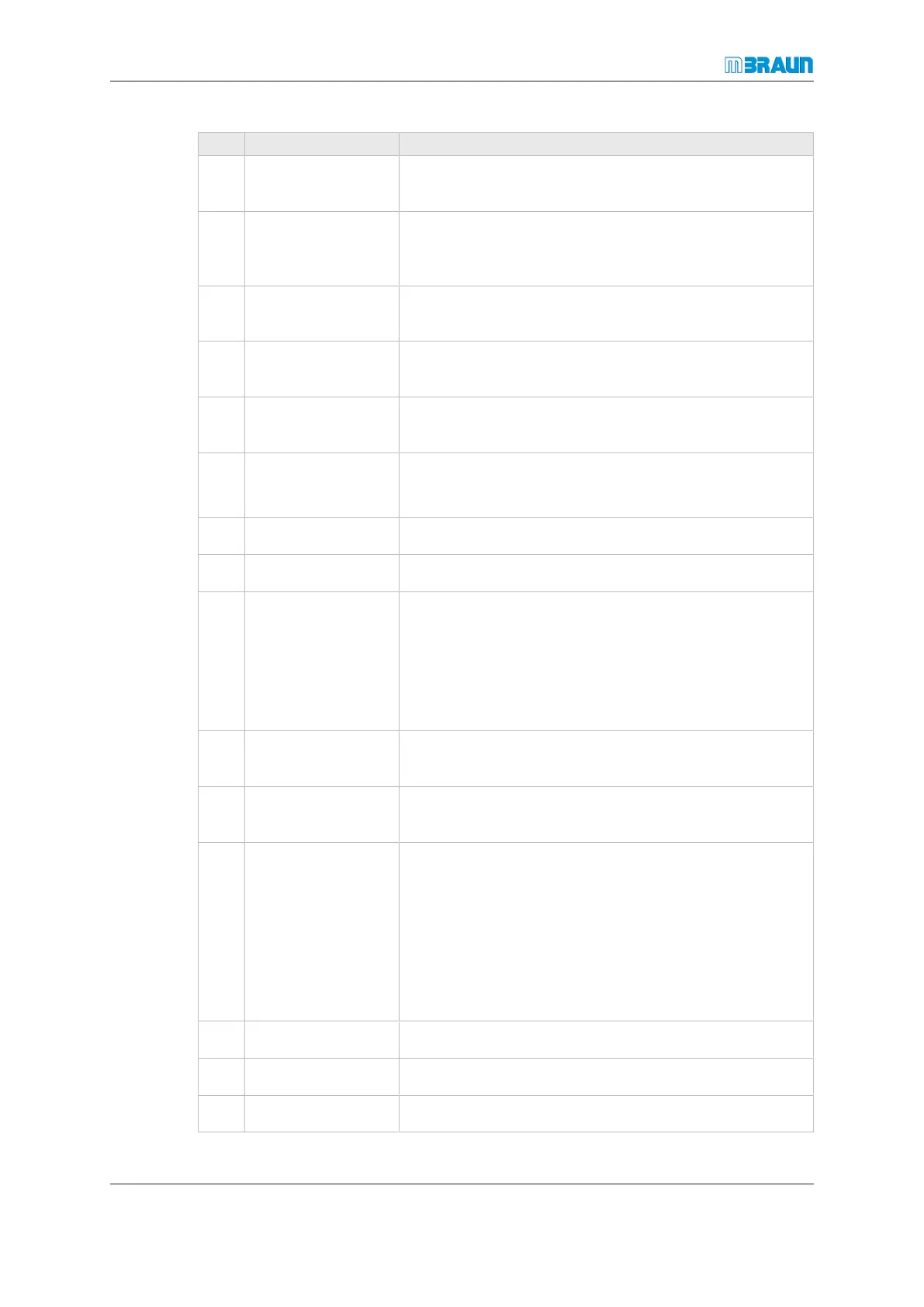

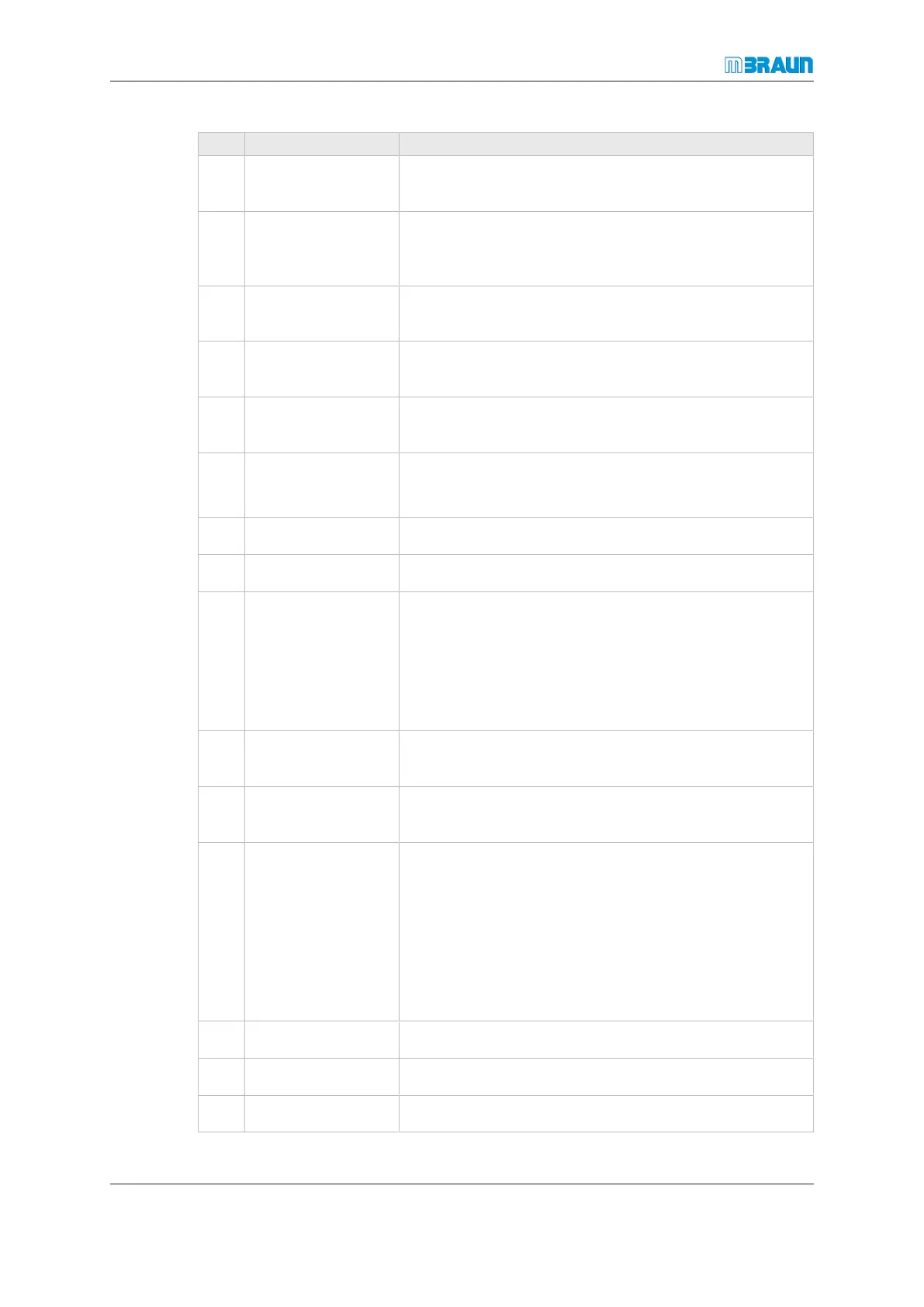

No. Component Function

1 Electrical cabinet Includes the electrical main connection, the connections

to the peripheral units and the system control.

2 Valve block Different electromagnetic valves control the purification

process, the regeneration process, pressure regulation

and further optional functions.

3 Manual adjustment

valve

Optional with box purge feature: valve for adjusting the

gas flow for the glovebox purge.

4 Exhaust Exhaust outlet for working gas to an in-house disposal

system.

5 Gas outlet pipe Gas outlet from the gas purifier to the glovebox/enclos-

ure.

6 Control gas outlet Control gas supply to external pneumatic valves

(antechamber and glovebox/enclosure).

7 3-way valve Inertisation of the solvent filter after exchange

8 Manometer Inertisation of the solvent filter after exchange

9 Heat exchanger Equipment to cool down the circulating gas.

The working gas is heated in the gas purifier by chemical

processes as well as by mechanical energy. The heat ex-

changer cools the working gas. In this manner, a con-

venient temperature inside the glovebox/enclosure is

maintained.

10 Circulation blower Exhausts contaminated gas out of the box or enclosure

and pushes the gas back as purified gas.

11 Vacuum pump Used for glovebox/enclosure pressure control, antecham-

ber cycles and regeneration cycles.

12 Media connections Connection plate for:

¡ Power for gas purifier and vacuum pump

¡ Working gas

¡ Regeneration gas

¡ Drain water

¡ Cooling water

13 Discharge opening To discharge exhausted activated carbon.

14 Refill opening To refill new, fresh activated carbon.

15 Gas inlet pipe Gas inlet from the glovebox/enclosure to the gas purifier.

Loading...

Loading...