SimradSU90

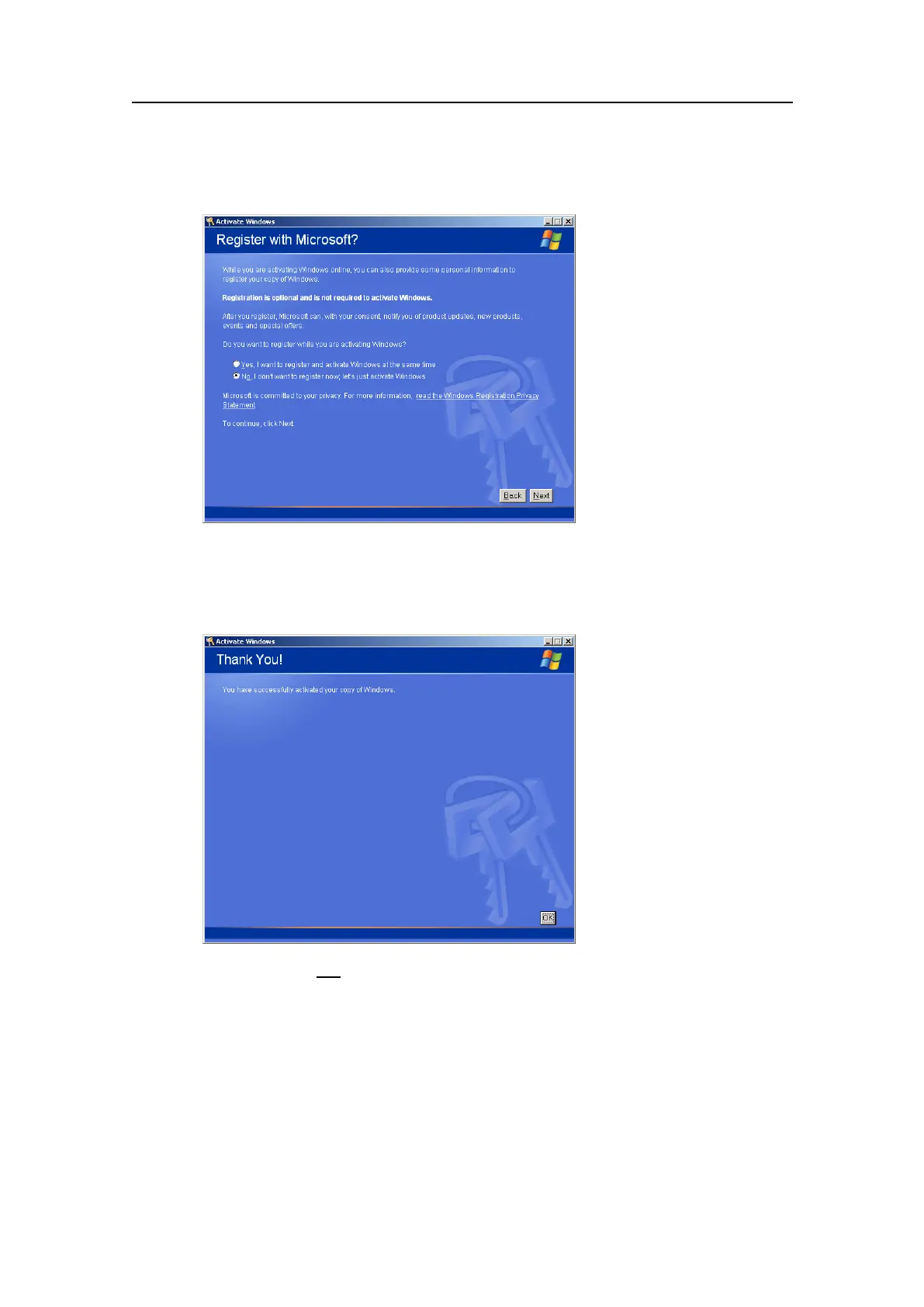

cObservethefollowingdialog:

dClickNo,Idon'twanttoregisternow....

eClickNext.

fObservethefollowingdialog:

15IfyourcomputerisnotconnectedtotheInternet.

aClickY es,Iwanttotelephoneacustomerservicerepresentative....

bClickNext.

216

381293/A

Loading...

Loading...