3. Repair Instructions 1/2010 3 - 107

BA-TE-DE08C M.KAY

Dialog SW9xx_sm_Chapter 3_1-2010.doc/pdf <100329> yymmdd

B. Braun Avitum AG

SW9.xx

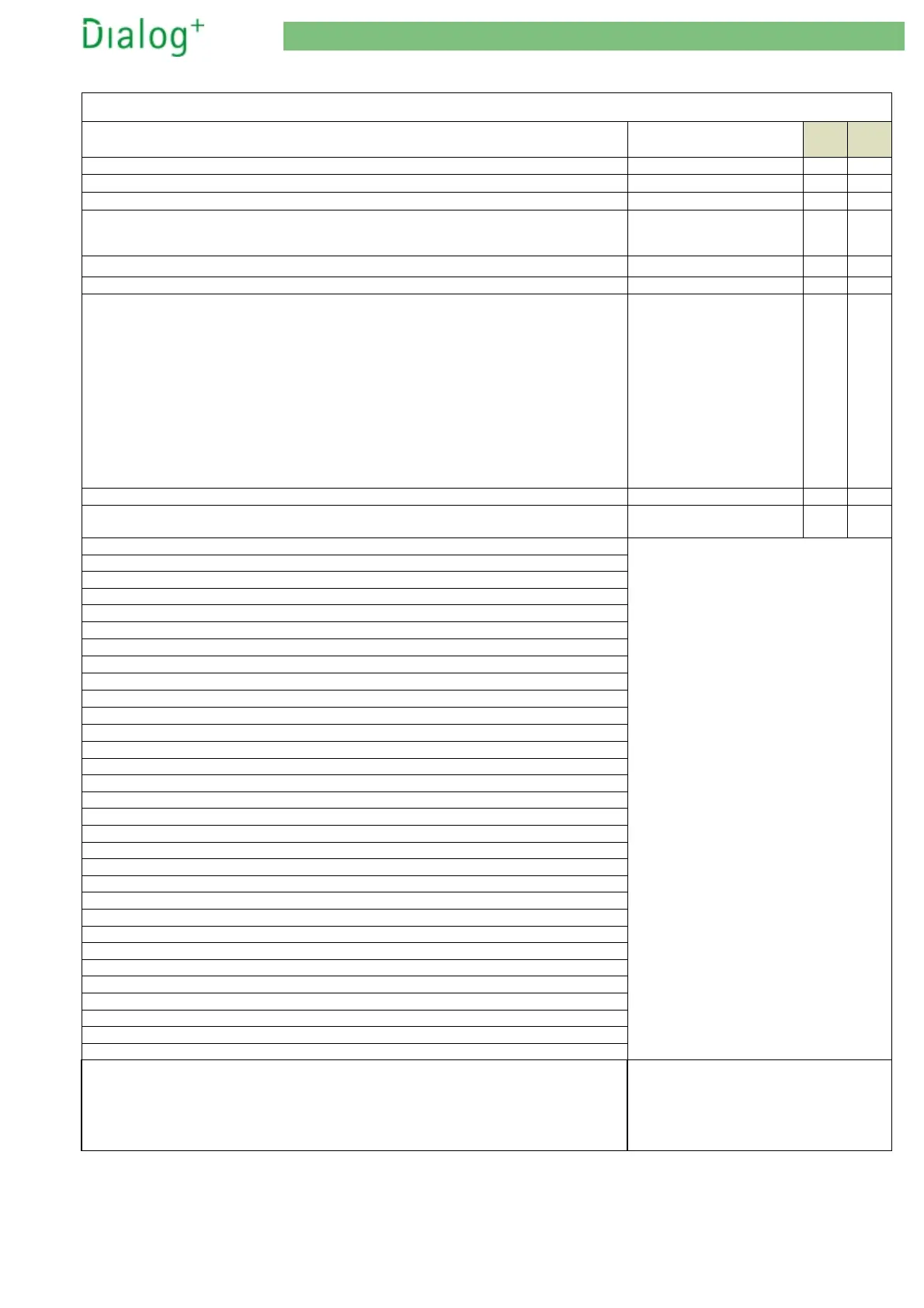

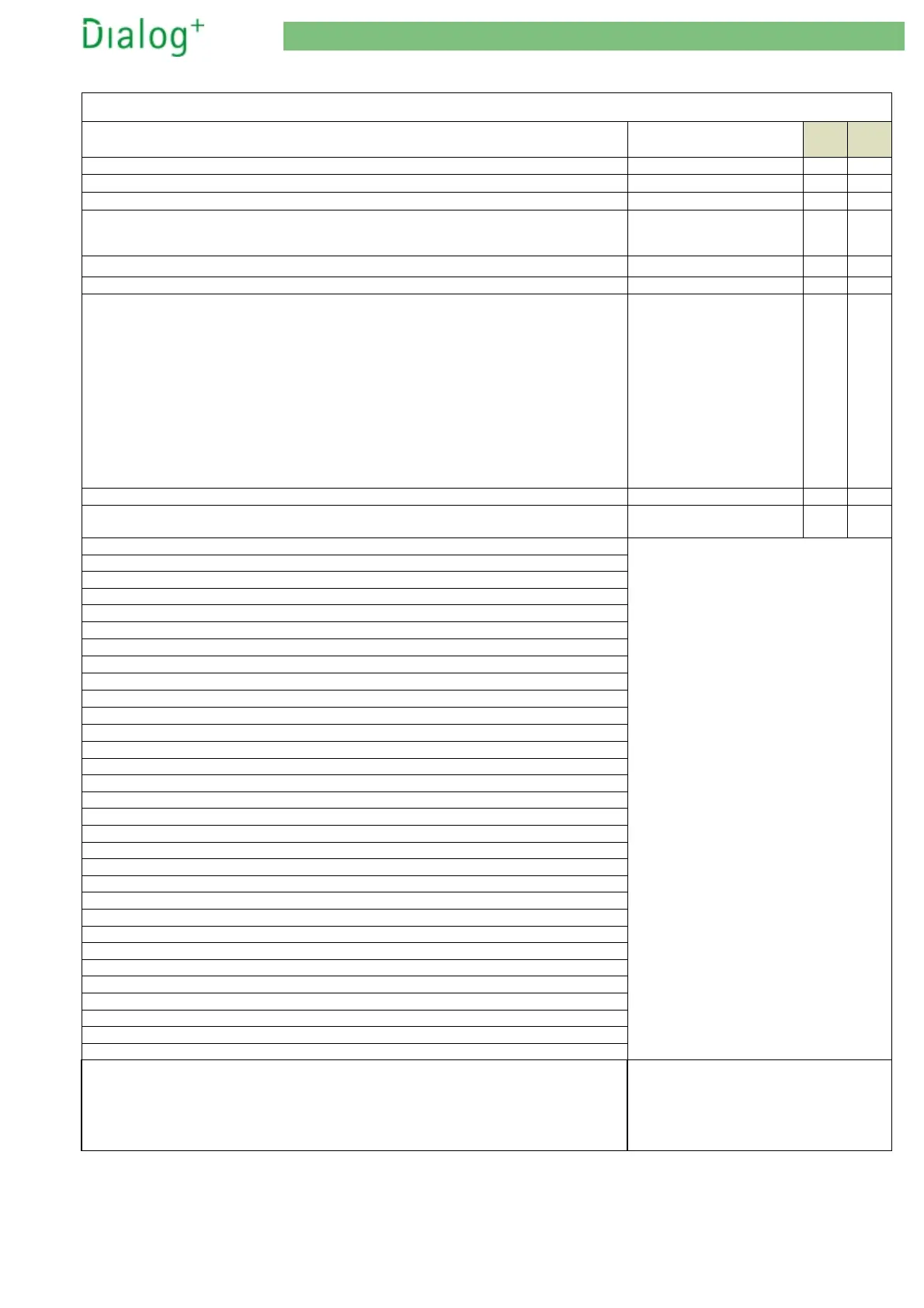

3.8.3 Execution Protocol

Execution Protocol

Measures According to Repair Matrix

Measurement Values/

Executed Measures

NA OK

3.8.2.1 Install Software

executed correctly

!!

3.8.2.2 Check System Configuration, Production Report and Set if Necessary

executed correctly

!!

3.8.2.3 Self Test

executed correctly

!!

3.8.2.4 Conductivity Test Run, Temperature

Comparison Measurement:

•

Conductivity (14.3 ms/cm, ±0.2)

•

Temperature (37

o

C, -1.5 +0.5)

...........................................

[mS/cm]

....................................................

[

o

C]

!!

3.8.2.5 Test Run UF Comparison Measurement:

•

15 min at UF rate 500 ml/h (3% ≈ ±4 ml)

....................................................

[ml]

!!

3.8.2.6 Test Run

executed correctly

!!

3.8.2.7 Electrical Safety Check:

According to:

IEC 62353/EN 60601-1/IEC 601-1

•

Protective Earth Resistance < 0.3 [Ω]:

Potential equalization bolt

Heater body (top)

Rinsing bridge (dialyser inlet and outlet)

Interior: front door (top left corner)

Interior: rear door (top left corner)

Interior: frame (rear)

Interior: housing cover (top left)

Monitor (one of the screws in the housing frame)

•

Equipment Leakage Current ≤ 0.5 [mA]:

•

Patient Leakage Current < 10 [µA] AC:

.....................................................

[

Ω

]

(note highest value)

..................................................

[mA]

...................................................

[µA]

!!

3.8.2.8 Perform Disinfection after Repair

executed correctly

!!

4. Tests and Calibrations According to Service Manual

All text in { } brackets are general notes or execution information!

executed correctly

!!

{4.9.1.1 Buttons, Lamps and Sounds}

{4.9.1.3 Touch Screen Calibration}

{4.9.1.8 DBI Test or DSI Test or DCI Test}

{4.9.2.1 Test 1.1 Staff Call, Alarms, Power Off}

{4.9.2.5 1.5 Tubing Clamps}

{4.9.2.7 Test 1.7 Air Sensor SAD, Red Sensor}

{4.9.2.8 1.8 Coupling Detectors}

{4.9.2.13 1.13 Balance Chamber Valves}

{4.9.2.14 1.14 Bypass and Disinfection Valves}

{4.9.2.19 1.19 Leak Test}

{4.9.2.23 Test 1.23 BIC Cartridge Valves and Coupling Detectors}

{4.9.2.25 1.25 HDF Online Valves and Detectors}

{4.9.2.26 1.26 Option Battery

{4.9.4.1 Calibration Pressure Sensors Blood Side PA, PV, PBE and PBS}

{4.9.4.3 Calibration Pressure Sensors of Water Side PE and PDA}

{4.9.4.4 Calibration Degassing TSE/TSHE}

{4.9.4.5 Calibration Dialysis Temperature Sensors TSBIC and TSD/TSD_S/TSDE}

{4.9.4.6 Calibration Conductivity Sensors BICLF and ENDLF/ENDLF_S}

{4.9.4.7 Calibration Blood Leak Detector Type 3}

{4.9.4.8 Calibration of Flow Rate UFP, BICP and KP}

{4.9.4.9 Calibration Safety Air Detector SAD Version 3}

{4.9.4.10 Calibration BICLF and ENDLF Ratio}

{4.9.4.13 Calibration Flow Rate of BPA and BPV/OSP}

{4.9.4.16 Calibration Inlet Flow Pump Nonreturn Valve RVFPE}

{4.9.4.17 Calibration Dialysate Nonreturn Valve RVDA}

{4.9.4.18 Calibration Outlet Flow Pump Nonreturn Valve RVFPA}

{4.9.4.19 Calibration Dialyser Inlet Throttle Valve DDE}

{4.9.4.20 Calibration Pressure Reducer Valve DMV}

{4.9.4.21 Gap SAKA and SAKV}

{4.9.4.23 Setting Servomotor for Disinfection Valve VD}

{5.1 Inspection Protocol for Automatic Blood Pressure Measurement ABPM}

The respective measures were executed correctly after servicing according to the

repair matrix.

Name Service Technician:

.............................................................................

.............................................................................

Date / Signature

Please use the repair matrix

for the necessary tests and

calibrations.

Loading...

Loading...