Brooks Automation 9. Maintenance and Repair

Part Number: 605914 Rev. B Repair Procedures

Lockout / Tagout

Workingwithenergizedequipmentmaycausesuddenmovementorelectricalshockand

mayresultindeathorseriousinjury.

l

Allenergymustberemovedfromtheequipmentperthefacility’s

Lockout/Tagoutprocedurebeforeservicing.

l

Iflocalproceduresarenotavailable,followtheprocedureforLockout/Tagoutin

OSHA Standard 29CFR 1910.147.

Procedure

Step Action

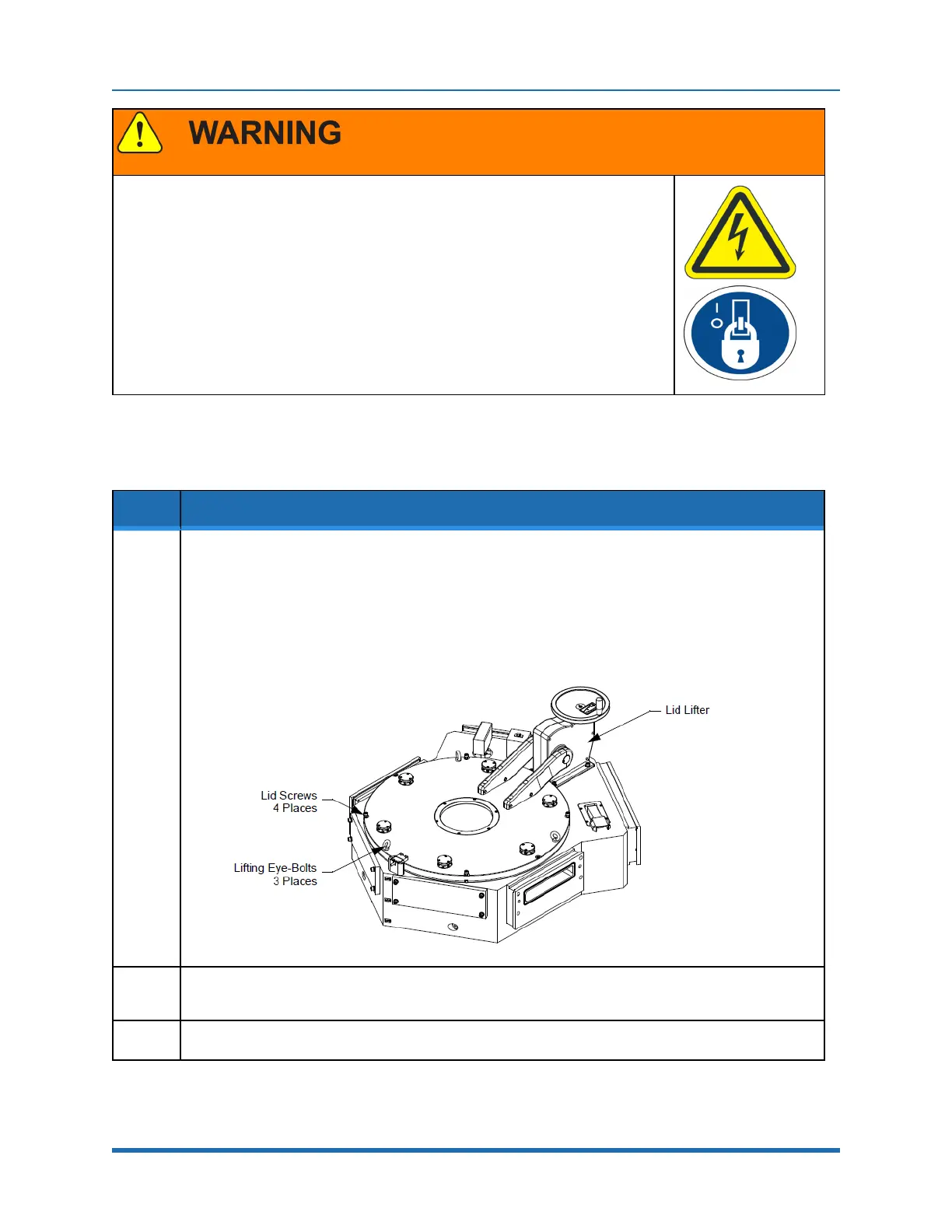

1.

a. Ensurethatallpower,communications,andairconnectionsareshutdownandthatthesystem

isventedtoatmosphericpressureasdetailedin"Shut-down"onpage1.

b. RemovetheLidLifter.Referto"LidLifterReplacement"onpage194.

c. Loosenthefourscrewssecuringthelidtothechamber.

d. Attachthreeliftingstrapsfromthehoisttothethreeeye-boltsonthelid.Thestrapsmustbe

appropriatelyratedandaminimumof914mm(3ft)long.

e. Removethelidfromthechamber,takingcarenottodamagethesealingsurfaceonthe

chamberoranyofthelidhardware.

2.

Removeallhardware(securingscrewsandsetscrews)fromtheoldlid.Ifnecessaryremovetheview-

portandthesensorreflectors,referto"Removing/ReplacingViewports"onpage189.

3.

Installthehardwareonthenewlid.

Copyright © 2023, Brooks Automation, Inc.

193

Loading...

Loading...