Brooks Automation 8. System Alignment

Part Number: 605914 Rev. B Vacuum Cassette Elevator Configuration and Alignment

Step Action

2.

Usingtherobot’sCDM,movetherobot’sarmoutoftheLoadLock’saccessslot.

SETUP -> STATIONS -> 1 -> CR -> LEARN R, T, BTO -> HAND LOCATE

a. Movetherobot’sarmwiththewaferoutoftheaccessslotandexituseofthevacuumrobot

usingtheCDM.

QUIT

3.

Removethewaferfromtheendeffectorandthegaugeblockfromtheaccessslot.

4.

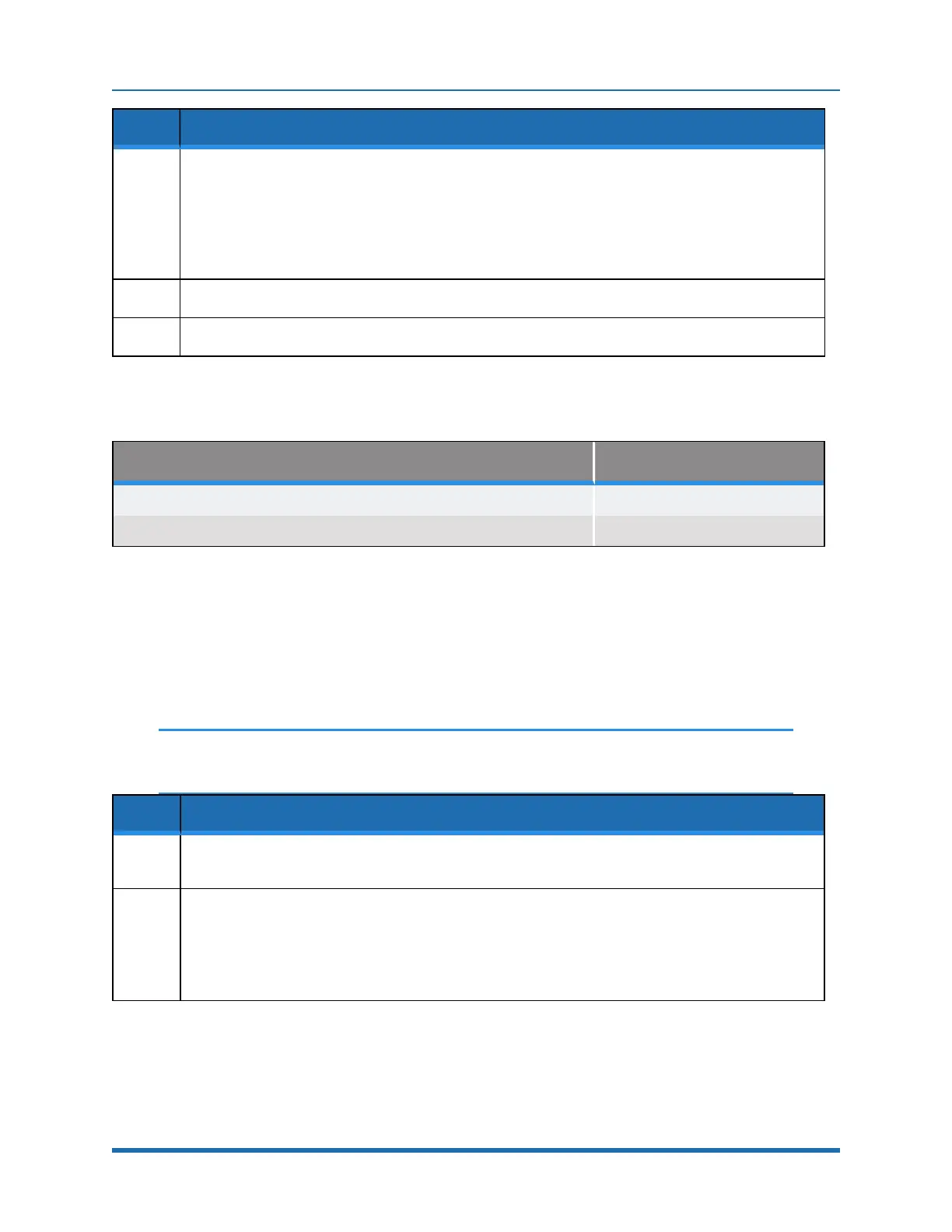

RefertoTable8-1andassignacalculatedvalueforthelift/lower(Z)movetoLWR(lower).

Wafer Size Lower Value

100mm,125mm,150mm(4in,5in,6in) 1.82mm(0.072in)

200mm(8inch) 2.25mm(0.089in)

Table 8-1: VCE Lower Values

Adjust the Load Lock Platform

TheplatformofeachLoadLockattachedtothesystemmustbeadjustedsothatwhentherobot’s

endeffectorisextended,andintheUPposition,awaferontheendeffectorwillbecentered

verticallyinthecurrentlypresentedcassetteslot.

NOTE: AllcassettesusedwithinLoadLocksattachedtotheMarathonExpressmust

meetSEMIMESCstandards.

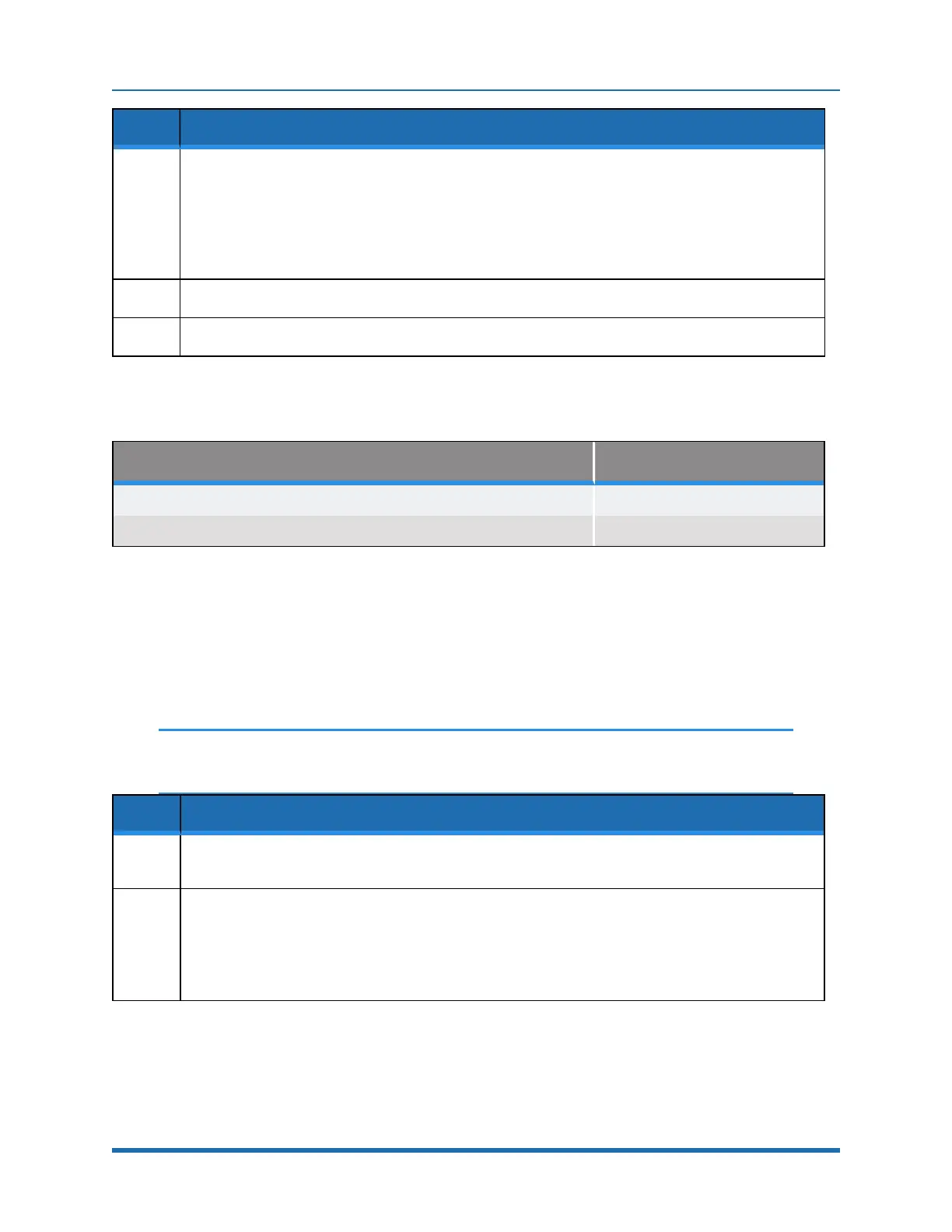

Step Action

1.

SettheplatformoftheLoadLocktoacceptthecassettetypethatwillbeused(refertotheBrooksAuto-

mationVCEUserManualforadjustments).

2.

HometheLoadLock.

00, A, HM

NOTE: Donot“home”theelevatorwhiletherobot’sarmsorendeffectorareextendedintotheLoad

Lock’schamberasseveredamagemayresult.

Copyright © 2023, Brooks Automation, Inc.

161

Loading...

Loading...