8. System Alignment Marathon Express

Vacuum Cassette Elevator Configuration

and Alignment

Part Number: 605914 Rev. B

Step Action

3.

SelecttheappropriateCassetteTypeOffset(CTO)configurationvaluefromtheBrooksAutomation

VCEUserManualandenteritusingtheSetCassetteTypeOffsetcommand,refertotheCommand

ReferenceintheVCEUserManual.

00, S, CF, CT, cto

NOTE: TheCTOisusuallysetatBrookswithrequesteddimensionscalculatedbythecassettesize.

BeforeresettingtheCTO,requestthevaluefirstandthenchangeonlyifnecessary.

4.

CommandtheVCEtoSlot1.

00, A, GO, 1

5.

RaisetheendeffectortotheUP(WTP)position.

6.

Extend(jog)therobot’sendeffectorintotheLoadLockandovertheplatform.

7.

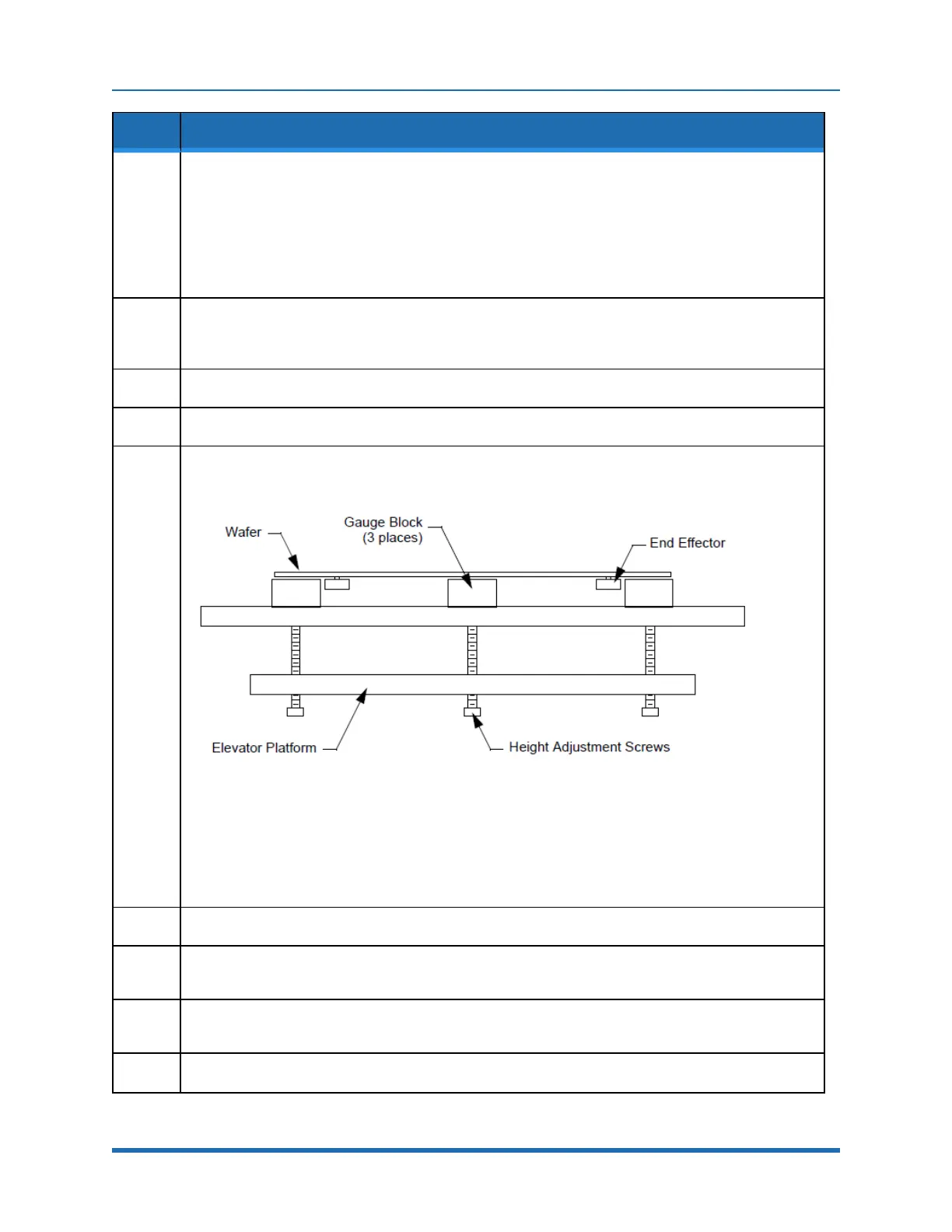

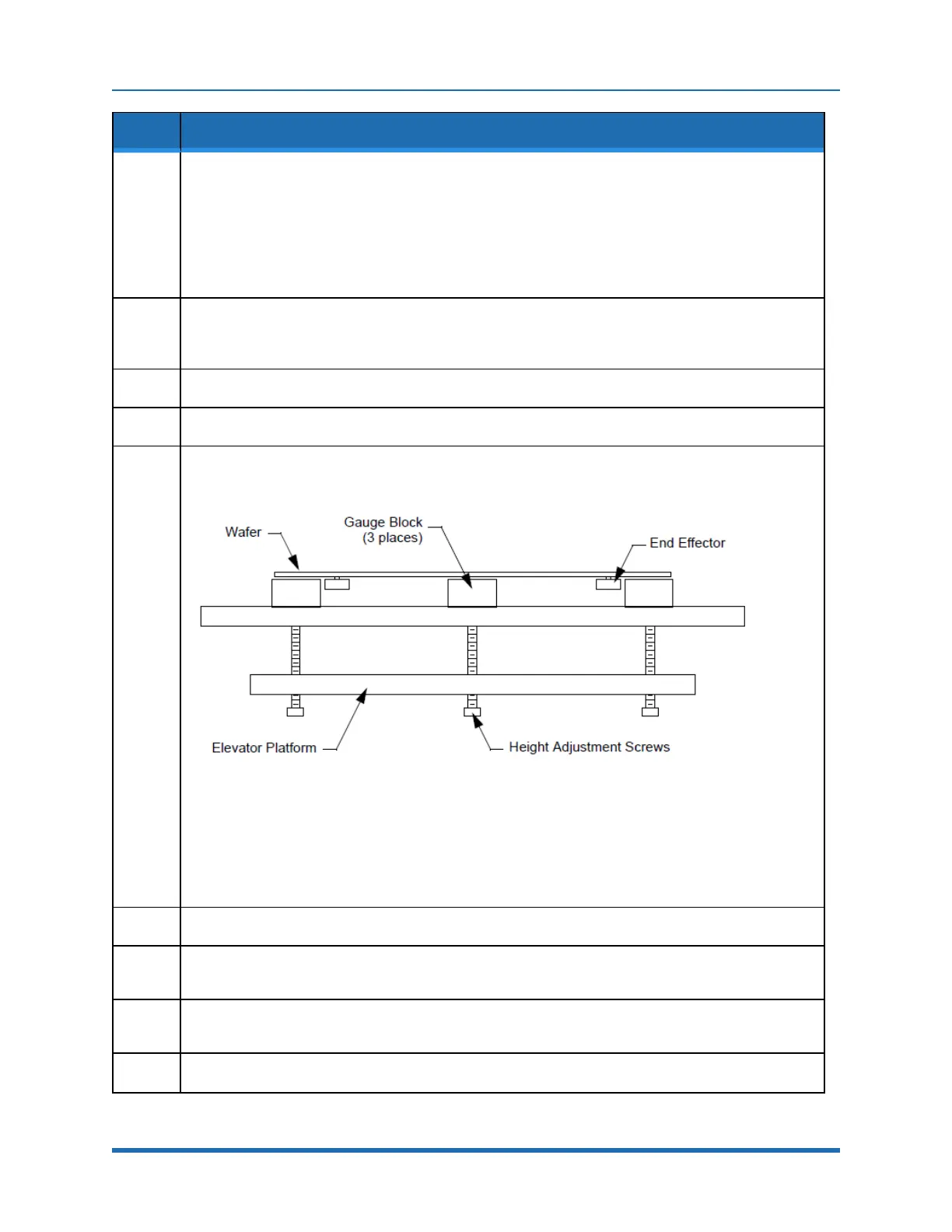

Locatethespring-loadedheight-adjustmentscrewsbeneaththeplatform,showninFigure8-3,and

placethreegaugeblocksontheplatformovertheheight-adjustmentscrews.RefertotheVCE

alignmentproceduresintheVCEUserManualorusethefollowinginstructions:

Figure 8-3: Platform Height Adjustment Screws

Forwafersupto150mmwafers,placethegaugeblocksontheplatformwiththe0.535inchdimension

orientedvertically.

For200mmwafers,placethegaugeblocksontheplatformwiththe0.985inchdimensionoriented

vertically.

8.

Placeanappropriatesizedwaferontotherobot’sendeffector.

9.

Sightingalongthebottomsurfaceofthewafer,adjusttheplatformheightadjustmentscrewsuntilthe

topsofthegaugeblocksjusttouchthebottomsurfaceofthewafer.

10.

Sightcarefullyalongtheendeffectortoinsurethatthewaferhasnotbeenliftedoffthesurface(moving

thegaugeblockshouldnotcausethewafertomove).

11.

Removethewaferandthegaugeblocksandretracttheendeffector.

162

Copyright © 2023, Brooks Automation, Inc.

Loading...

Loading...