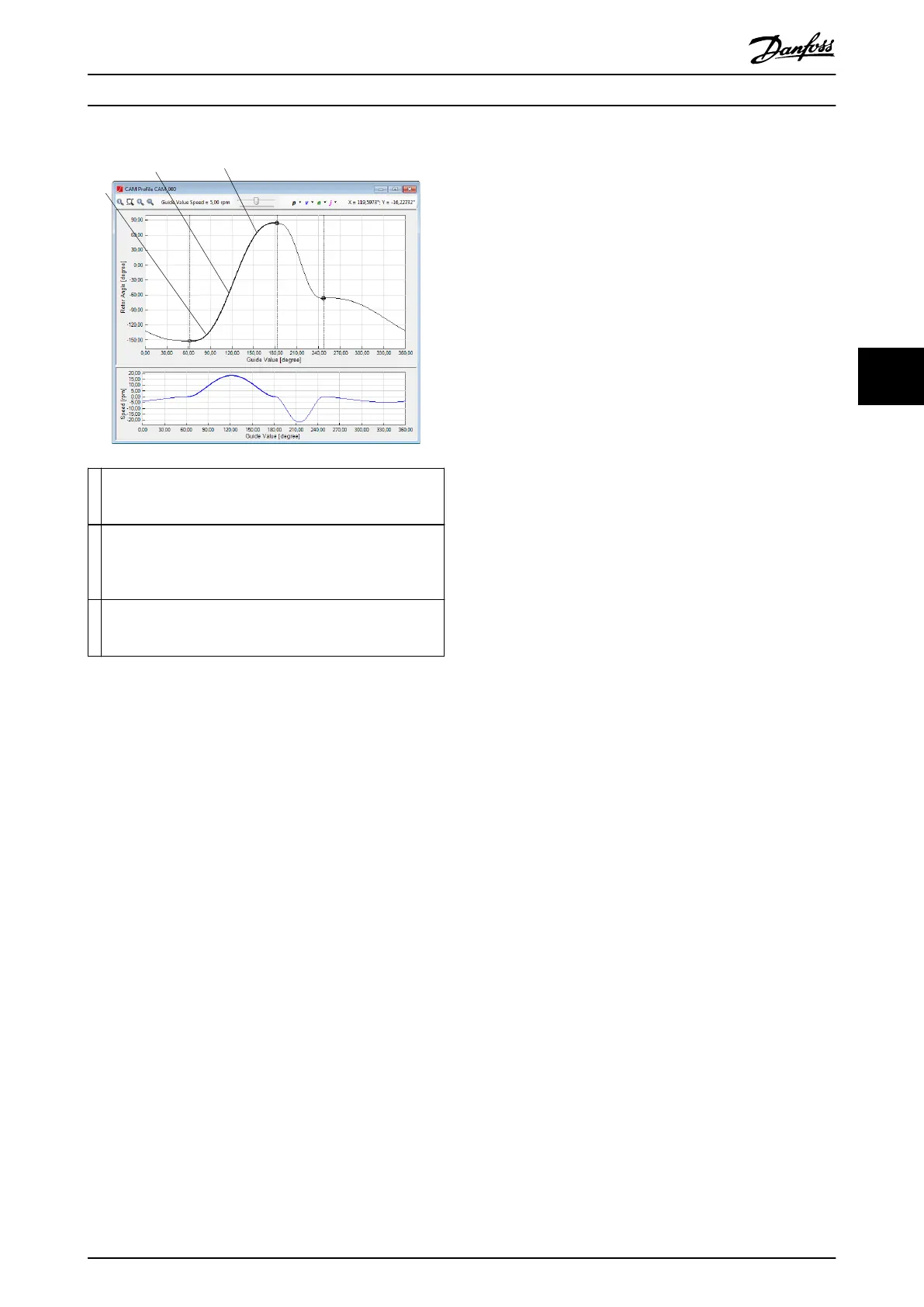

1 By dragging the left side of the segment (near to its

preceding guide node), only the start position of the segment

is changed.

2 By dragging the center of the segment, both the start

position and the end position of the segment are changed

and the segment is thus moved up or down.

3 By dragging the right side of the segment (near to its

succeeding guide node), only the end position of the segment

is changed.

Illustration 5.73 Graphically Editing a Guide Poly

Move Distance segment

The Move Distance segment has the following properties:

•

Parameters

- Start position: Species the axis position

at the beginning of the segment,

relative to the end position of the

previous segment. If the parameter is

left blank (unspecied), the logical CAM

position from the previous segment is

used as the starting position.

•

Start

- Start acceleration: Species the

acceleration of the axis at the beginning

of the segment. It is the same as the

start acceleration of Guide poly.

- Start velocity: Species the velocity of

the axis at the beginning of the

segment. It is the same as the start

velocity of Guide poly.

•

End

- End acceleration: Species the

acceleration at the end of the segment.

For more information, see Start

acceleration.

- End velocity: Species the velocity at

the end of the segment. For more

information, see Start velocity.

When the position of the preceding node or succeeding

node of a move distance segment is changed (graphically

or numerically), the segment is automatically recalculated

and redrawn.

When any of the move distance segment properties are

changed by using the Property Window, the segment is

automatically recalculated and redrawn.

The move distance segment is calculated with the aid of

the Simulated angle property. This can be used for testing

the result of dierent angles sent to the drive. The default

value is 0°.

The start position or simulated angle property values

cannot be edited graphically. Use the Property Window to

change them.

Return segment

The Return segment has the following properties:

•

Parameters

- Start position: Species the axis position

at the beginning of the segment,

relative to the end position of the

previous segment. If the parameter is

left blank (unspecied), the logical CAM

position from the previous segment is

used as the starting position.

- Partition: Species the number of

equivalent positions that can be used by

the drive. The reference position is

determined by the absolute position at

the beginning of the segment and the

partition. This parameter can be used

for shaped plates when several equal,

valid starting positions are allowed. The

worst case movement is inuenced by

this parameter. Set the value to 0 to

disable this feature.

- Revolutions: Number of revolutions that

are used when calculating valid

positions, for example if there is a gear.

- Oset: Desired end rotor position

relative to the nearest physical position.

The reference position is determined by

the absolute position at the beginning

of this segment and the partition.

•

Information (all read-only)

Operation with ISD Toolbox Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 151

5 5

Loading...

Loading...