2.5.3 Guide Value

The guide value is used in all synchronous modes of

operation (CAM mode and Gear mode). It is used as the

master position within the synchronous modes. The guide

value consists of a position value (see

chapter 7.8.1 Parameter: Position Guide Value (0x2060)) and

an optional velocity value (see chapter 7.8.2 Parameter:

Velocity Guide Value (0x2064)).

The servo drive also supports a scaling of the guide value.

The scaling factor (see chapter 7.8.4 Parameter: Guide Value

Scaling Factor (0x3808)) consists of a numerator and a

denominator.

The Position guide value is multiplied by the quotient of

numerator and denominator.

Guide value scaled = Guide value x Scaling factor + Guide value oset

(Internally used = 0x2060 x 0x3808.01/02 + 0x3806)

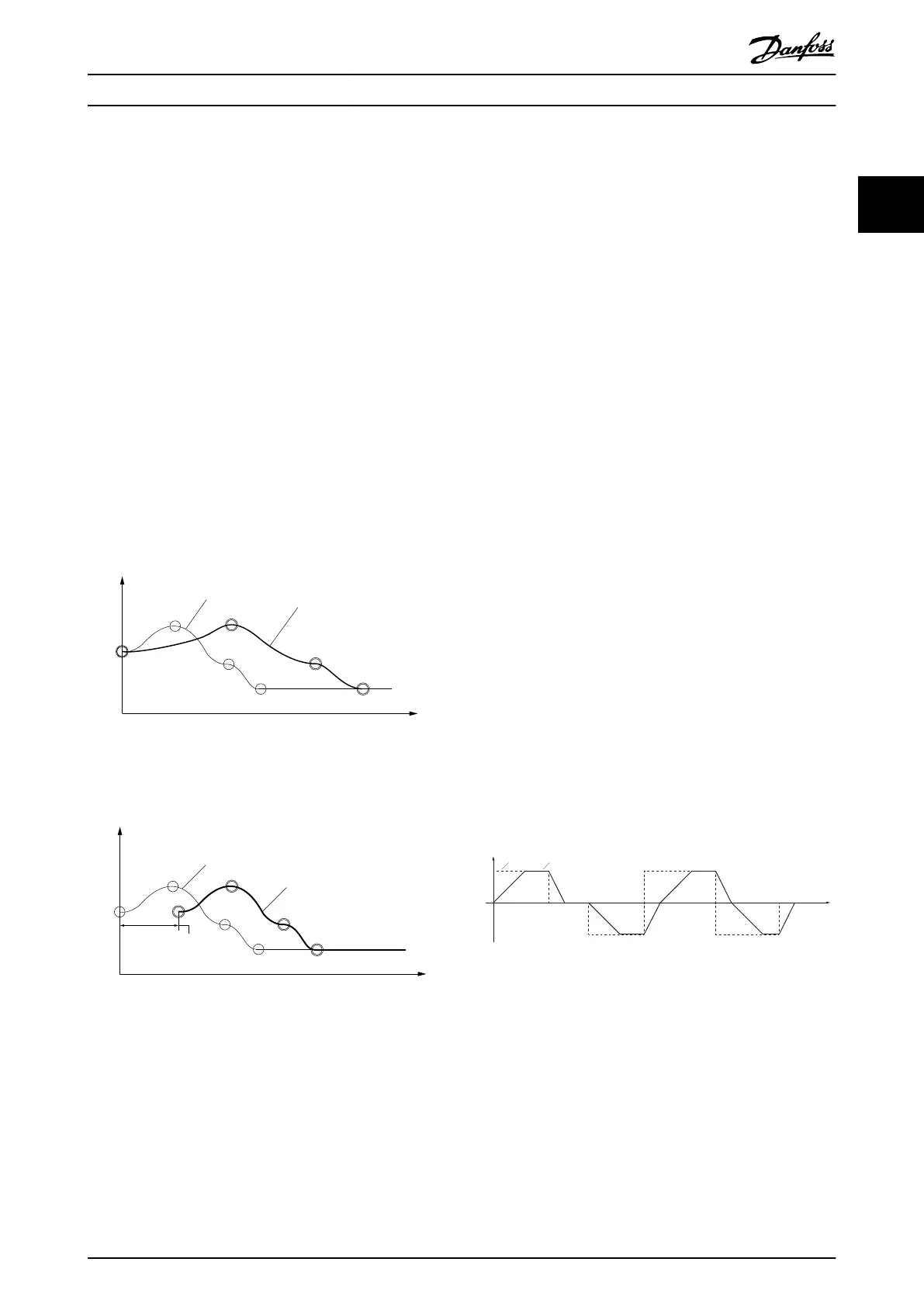

Rotor angle of axis

Master axis / guide value

Original CAM

prole

Used CAM prole

(Original guide value

multiplied with master

scaling factor)

Illustration 2.130 Example of Guide Value Scaling in CAM

Mode

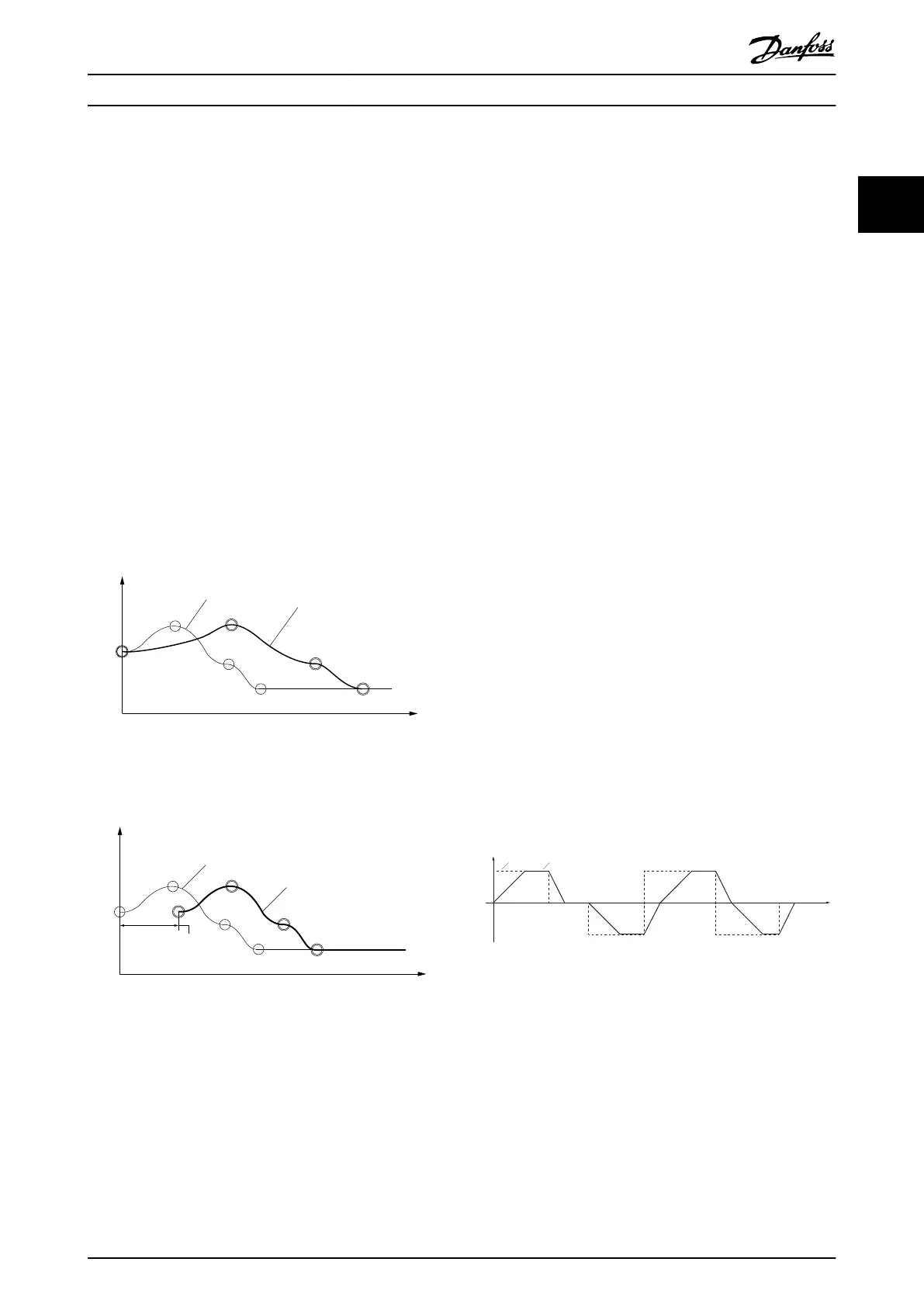

Rotor angle of axis

Master axis / guide value

Original CAM

prole

Used CAM prole

(Original + master oset)

CAM master oset =

Guide value oset

130BF214.10

Illustration 2.131 Example of Position Guide Value Oset in

CAM Mode

When receiving a guide value, the servo drive can

optionally check the value against reversing and jumps in

the position using object 0x2061 (see

chapter 7.8.3 Parameter: Guide Value Option Code (0x2061)).

Using this object, the servo drive can also be instructed to

calculate the guide value velocity.

The guide value objects can be found inchapter 7.8 Guide

Value Objects.

2.5.3.1 Guide Value Reference

The servo drive is also able to provide a guide value that

can be used, for example, by the PLC. This generated guide

value is called Guide value reference. It consists of the

position and the velocity. The servo drive can provide

these values based on dierent sources.

Possible guide value reference sources are:

•

External encoder

•

Simulation

•

Actual target position

- Actual position

- Set position

Select 1 of these using object 0x2063 (see

chapter 7.9.3 Parameter: Guide Value Reference Option Code

(0x2063)). The objects to inuence the guide value

reference can be found in chapter 7.9 Guide Value Reference

Objects.

2.5.3.2 Guide Value Reference Simulation

A guide value reference simulation functionality is

provided (activate/deactivate guide value reference

simulation) by the servo drive. Velocity, acceleration, and

speed limits can be parameterized.

The guide value reference simulation can also be used as a

virtual axis in a real application. The guide value reference

simulation can be useful in commissioning scenarios when

it is not possible/appropriate to use the entire machine.

The guide value reference simulation can then be used to

simulate that the main axis is moving.

Target velocity

Velocity

acc

0

dec

acc dec acc dec

acc dec

Illustration 2.132 Usage of Acceleration and Deceleration in

GuideValue Reference Simulation

The device puts the calculated position and the velocity

into the reference objects (see chapter 7.9.1 Parameter:

Position Guide Value Reference (0x2062) and

chapter 7.9.2 Parameter: Velocity Guide Value Reference

(0x2065)) every cycle while increasing or decreasing the

simulation speed with the desired ramp acceleration until

the demanded speed has been reached.

The guide value reference simulation can be parameterized

with the objects given in chapter 7.9.6 Guide Value

Reference Simulation.

Servo Drive Operation Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 85

2 2

Loading...

Loading...