32

SECTION 5 - REMOVAL - REFITTING OF THE MAIN ENGINE COMPONENTS

CURSOR SERIES

Base - 03/2015 Print P4D32C006 E

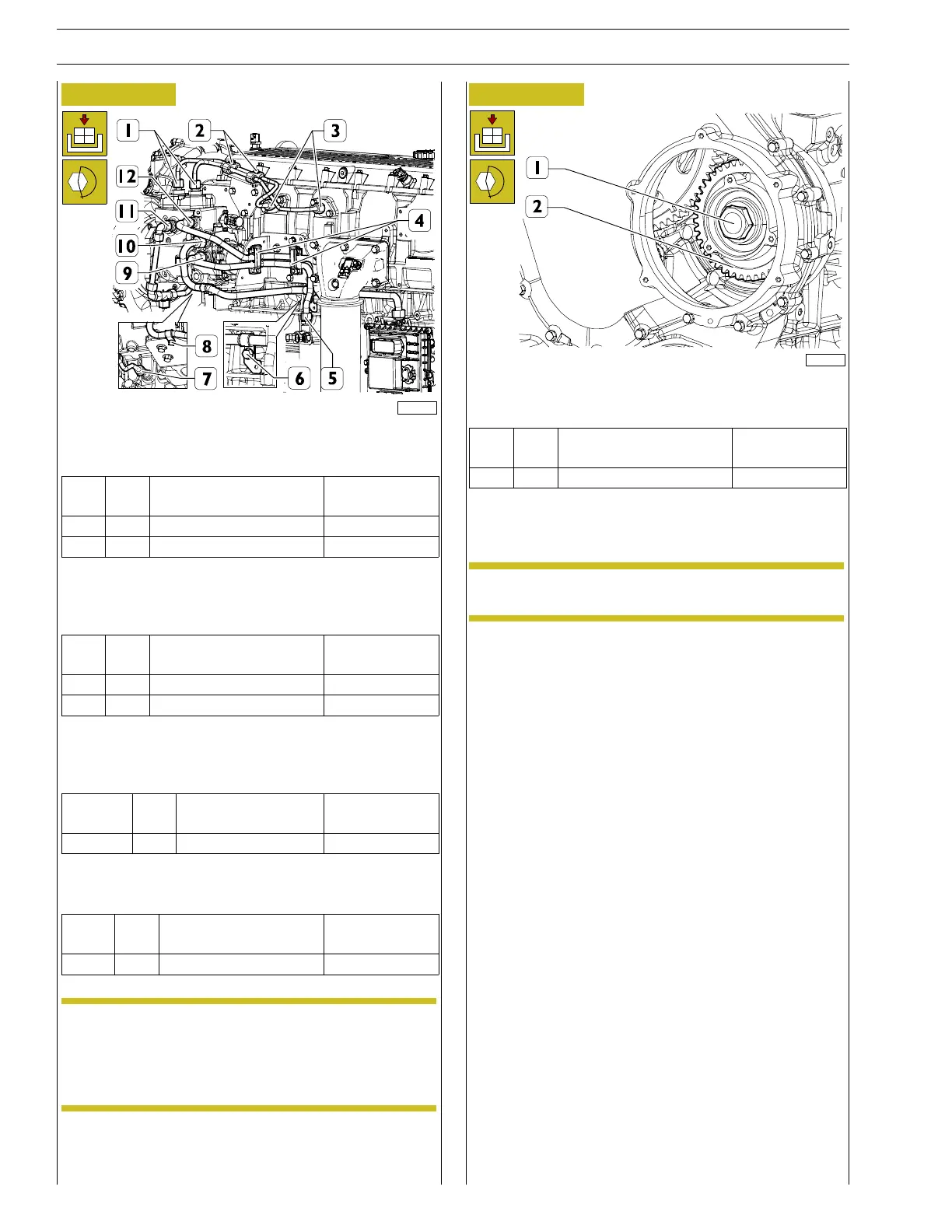

Figure 87

227770

Fit the HP fuel pipes, fit the plugs onto the bracket and tighten

the fittings (1, 3) and nuts to the torque (2) shown in the table.

Ref.

No. Description

Tightening

torques

(1, 3) 4 Fittings M16 X 1.5 42.5±2Nm

(2) 2 Nuts M6 X 1 8±2Nm

Position the LP fuel pipe from control unit to pump, tighten the

fitting (10)and bracket screws (6, 8) to the torque shown in the

table.

Ref.

No. Description

Tightening

torques

(10) 1 Fitting M22 X 1.5 50 ± 5 Nm

(6, 8) 2 Screws M8 X 1.25 X 16 24.5 ± 2.5 Nm

Position the LP fuel pipe from pump to filter and vivc-versa and

tighten fittings (5, 9, 12) to the torque shown in the table. close

springs (4).

Ref.

No. Description

Tightening

torques

(5, 9 12) 4 Fittings M18 X 1.5 37 ± 3 Nm

Fit the new fuel return pipe (7, 11) and tighten the fittings to

thetorqueindicatedinthetable.

Ref.

No. Description

Tightening

torques

(7, 11) 2 Fittings M18 X 1.5 37 ± 3 Nm

NOTE Make sure that the pipe is not damaged after

mounting and that there are no fuel leaks while

engine is running.

The HP pipes that are disassembled cannot be

used again and must be replaced.

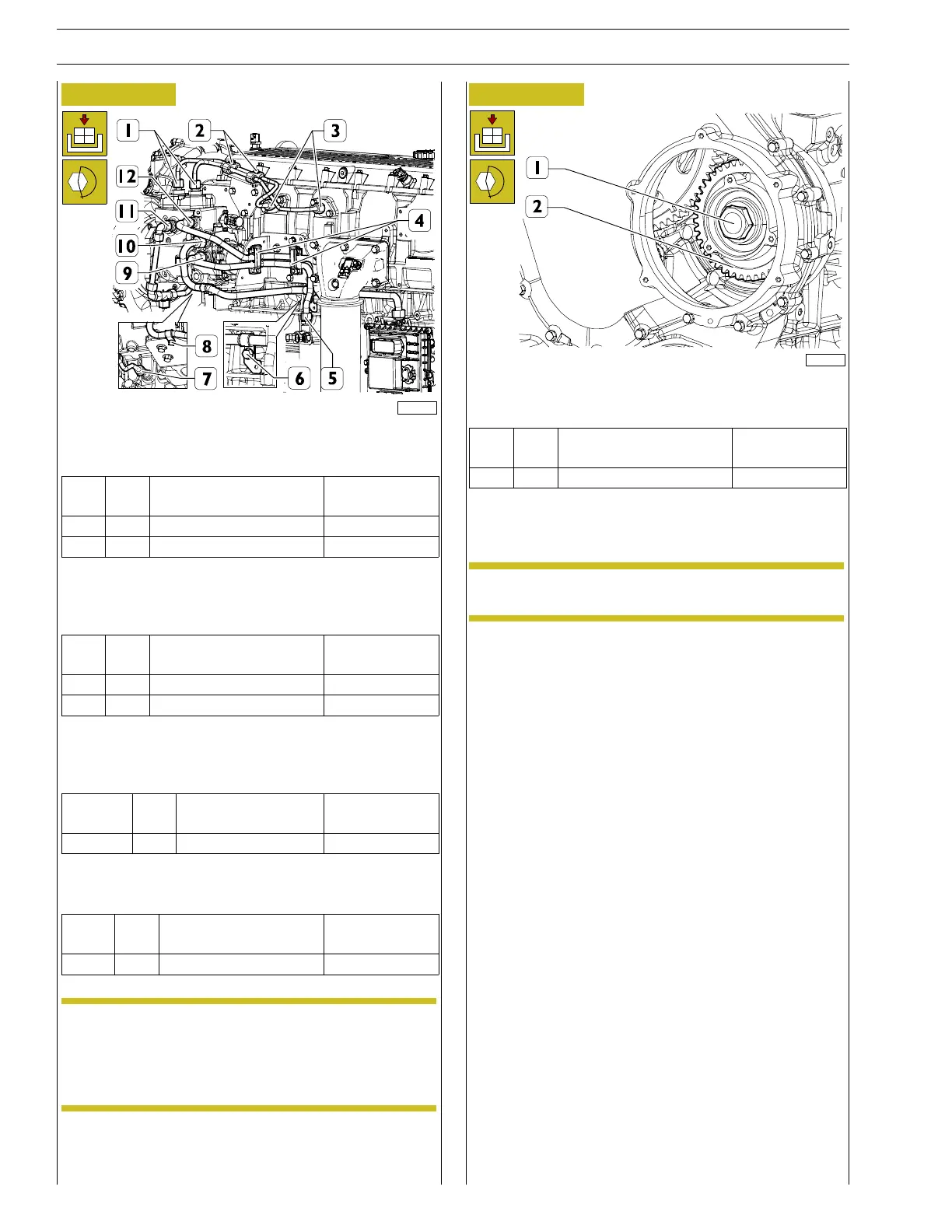

Figure 88

225037

Fit the gear (2) and tighten the nut (1) to the torque shown

in the table.

Ref.

No. Description

Tightening

torques

(1) 1 Nut M24 X 1.5 275 ± 25 Nm

Connect the electrical connection from the fuel flow regulator.

Remove the tool 99360351 for engine flywheel locking.

NOTE Carefully clean the seating of the filter and the

cover.

Loading...

Loading...