178241

190509

Figure 5 Figure 6

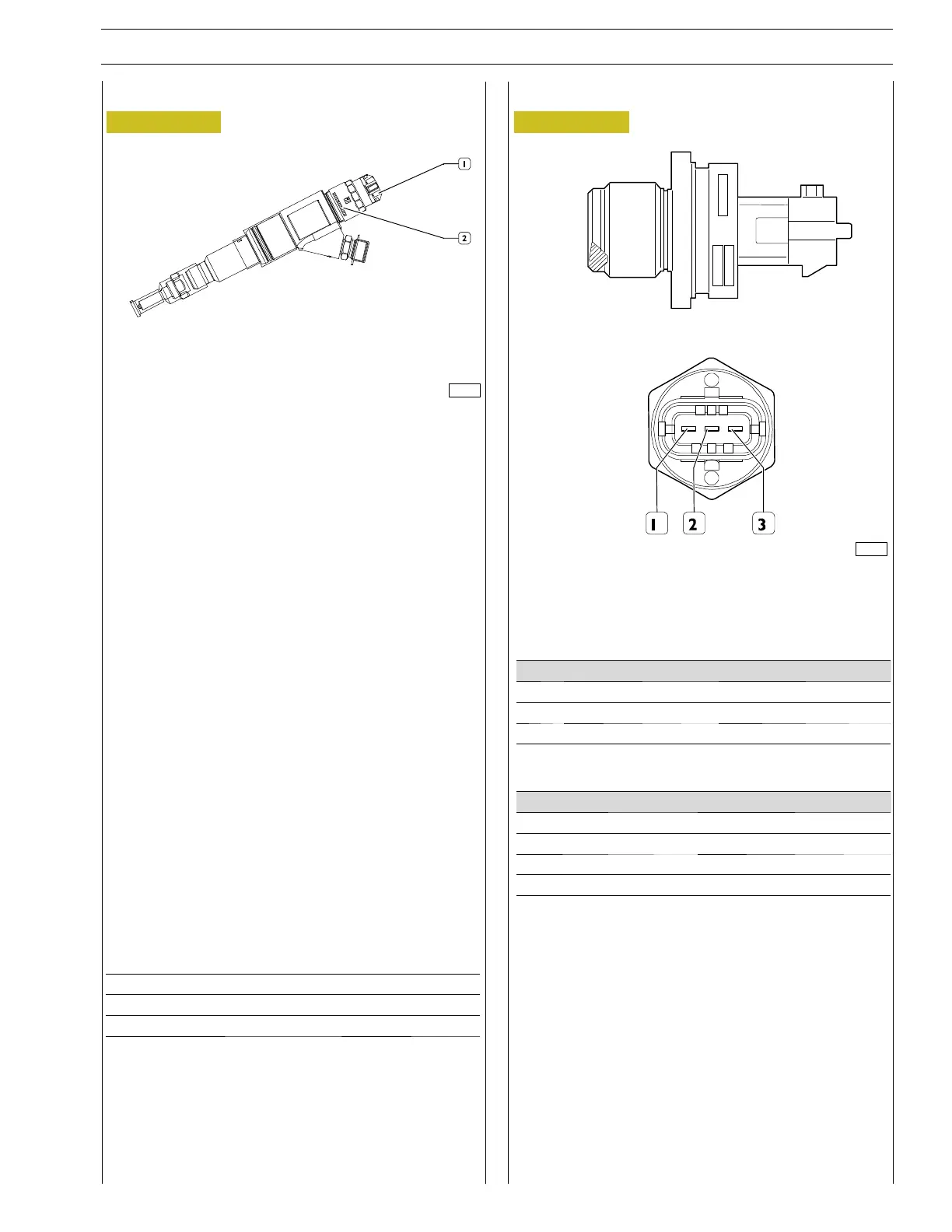

CRIN INJECTOR 3.3

1. Electrical connections - 2. Electromagnet assembly

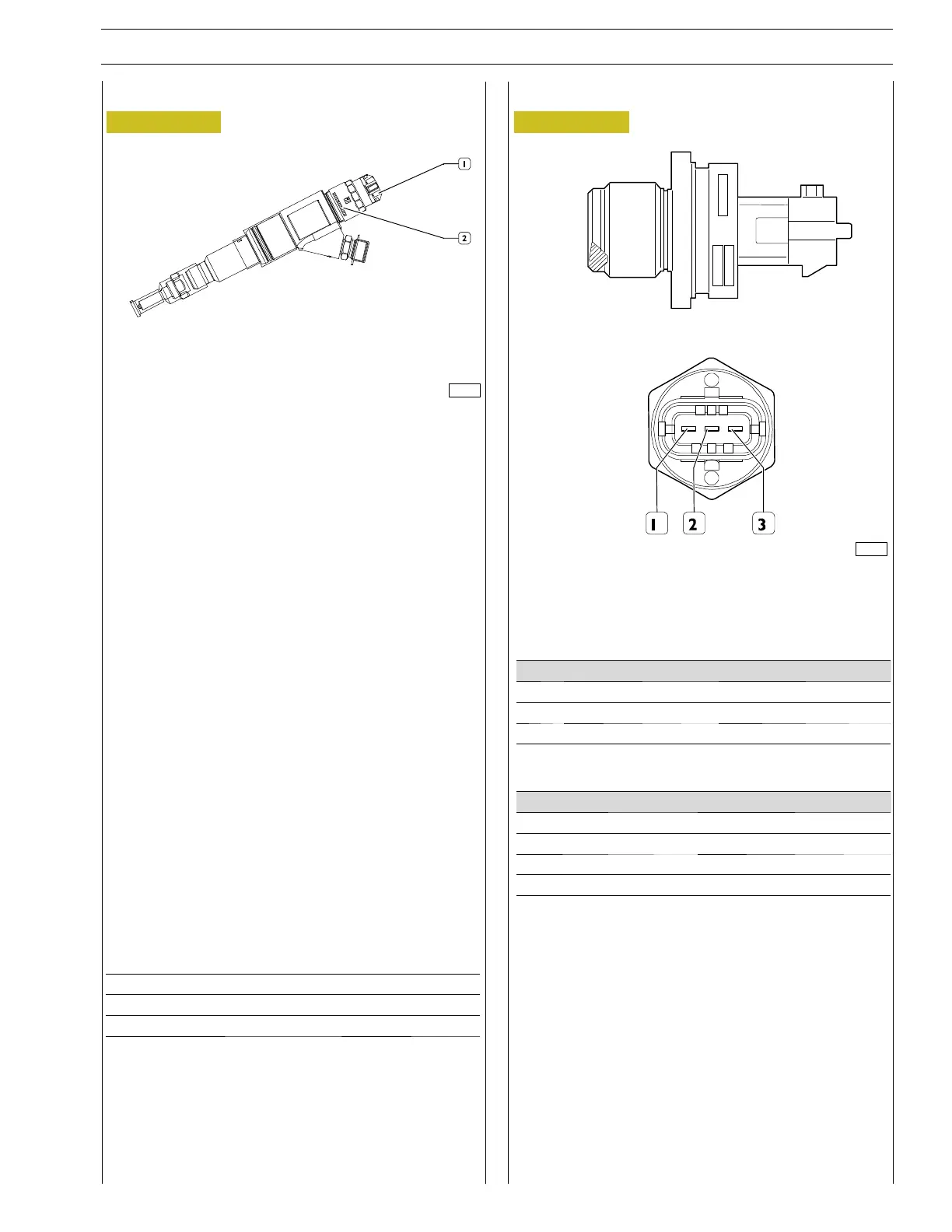

Rail pressure sensor (RSD 4)

The value of injection pressure is used to keep the pressure

level under control and to determine the time duration of the

injection electronic command.

This is an N.O. solenoid valve.

They are connected to the EDC ECU on connector 2.

The resistance of the coil of each individual injector is 0.56

-0.57.

The electro-injector essentially consists of two parts:

- actuator - spray nozzle consisting of a pressure rod, a

needle and a jet

- control solenoid valve made up of coil and pilot valve

The solenoid valve checks the lift of the nozzle needle.

START OF INJECTION

Upon being supplied with power, the coil moves up the shut-

ter. The fuel in the control volume flows back towards the

return duct resulting in a pressure drop in control volume.

Atthesametime,thefuelpressureinthepressurechamber

moves up the needle resulting into the fuel being injectedinto

the cylinder.

END OF INJECTION

When power to the coil is cut off, the shutter closes again

so as to re-create an equilibrium which moves the needle

back into its closed position and stops the injection process.

SECTION 3 - ELECTRIC EQUIPMENT

9

CURSOR SERIES

Print P4D32C006 E Base - 03/2015

Maximum working pressure 1,800 bar

Minimum working pressure 250 bar

Electrical connection M4 nut 1.5 ±0.25 Nm

Pin Description ECU pin

1 Ground (-) EDC17, pin A/60

2 Signal (Output) EDC17, pin A/36

3 Power supply (+) EDC17, pin A/11

Specifications Measurement Conditions

Pressure range 0 - 2,400 bar

Power supply 5V

Output voltage 0.5 - 4.5V

Closing torque 140 Nm

Loading...

Loading...