SECTION 6 - GENERAL MECHANICAL OVERHAUL

55

CURSOR SERIES

Print P4D32C006 E Base - 03/2015

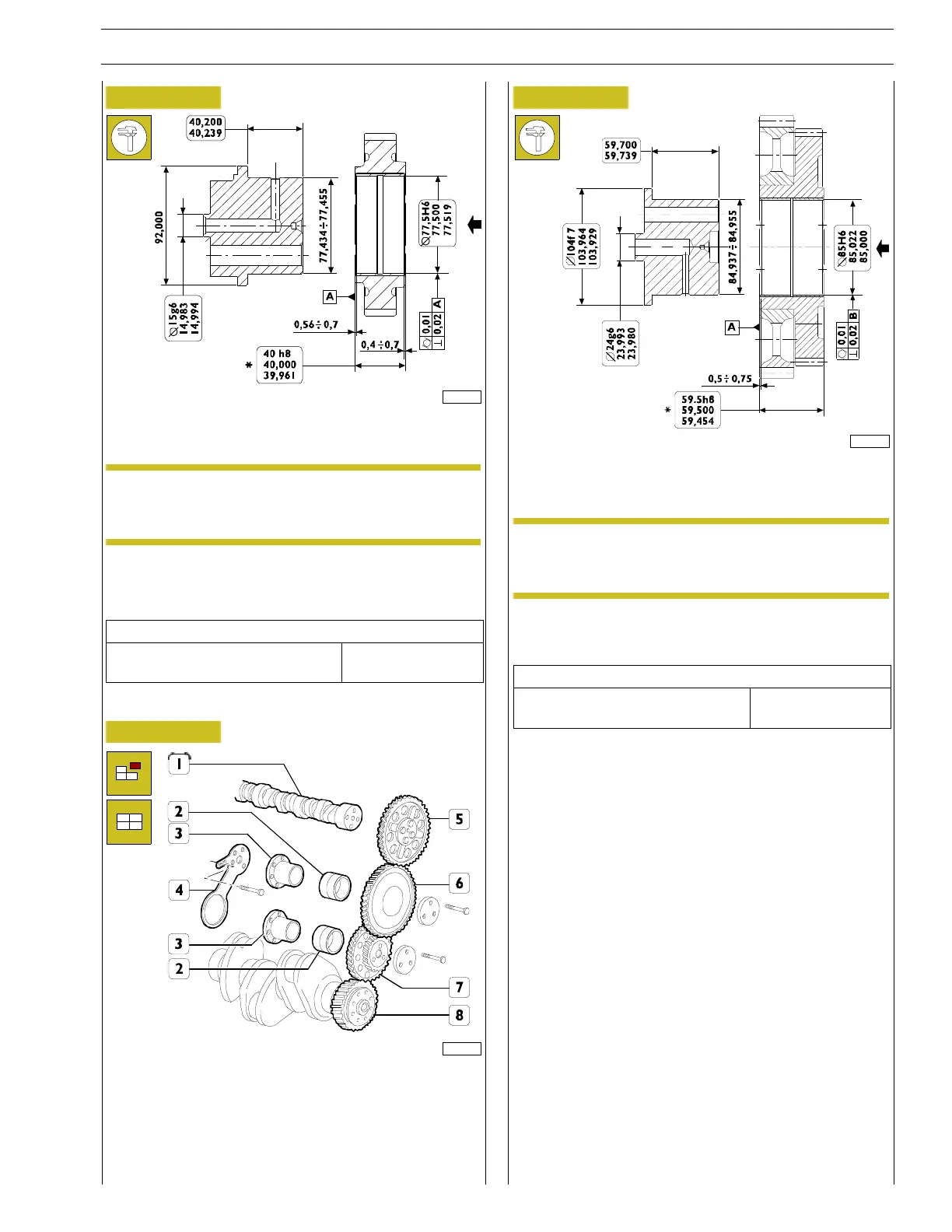

Figure 125

225002

After driving the bushing, bore it to obtain the diameter shown

in the figure.

NOTE The bushing must be driven into the gear in the

direction of the arrow setting the latter to the

dimension shown.

At the end of the boring operation, check that the gear

bushing/journal assembly clearance is equal to the indicated

value.

Technical data

rated assembling clearance

between gear bushings and pins

0.045 - 0.085 mm

Replacement of the dual idle gear bushes

Figure 126

225001

1. Camshaft - 2. Bushing - 3. Pin - 4. Connecting rod -

5. Camshaft l control gear - 6. Transmission gear - 7. Double

transmission gear - 8. Crankshaft driving gear

Replace the bushings (2) when worn.

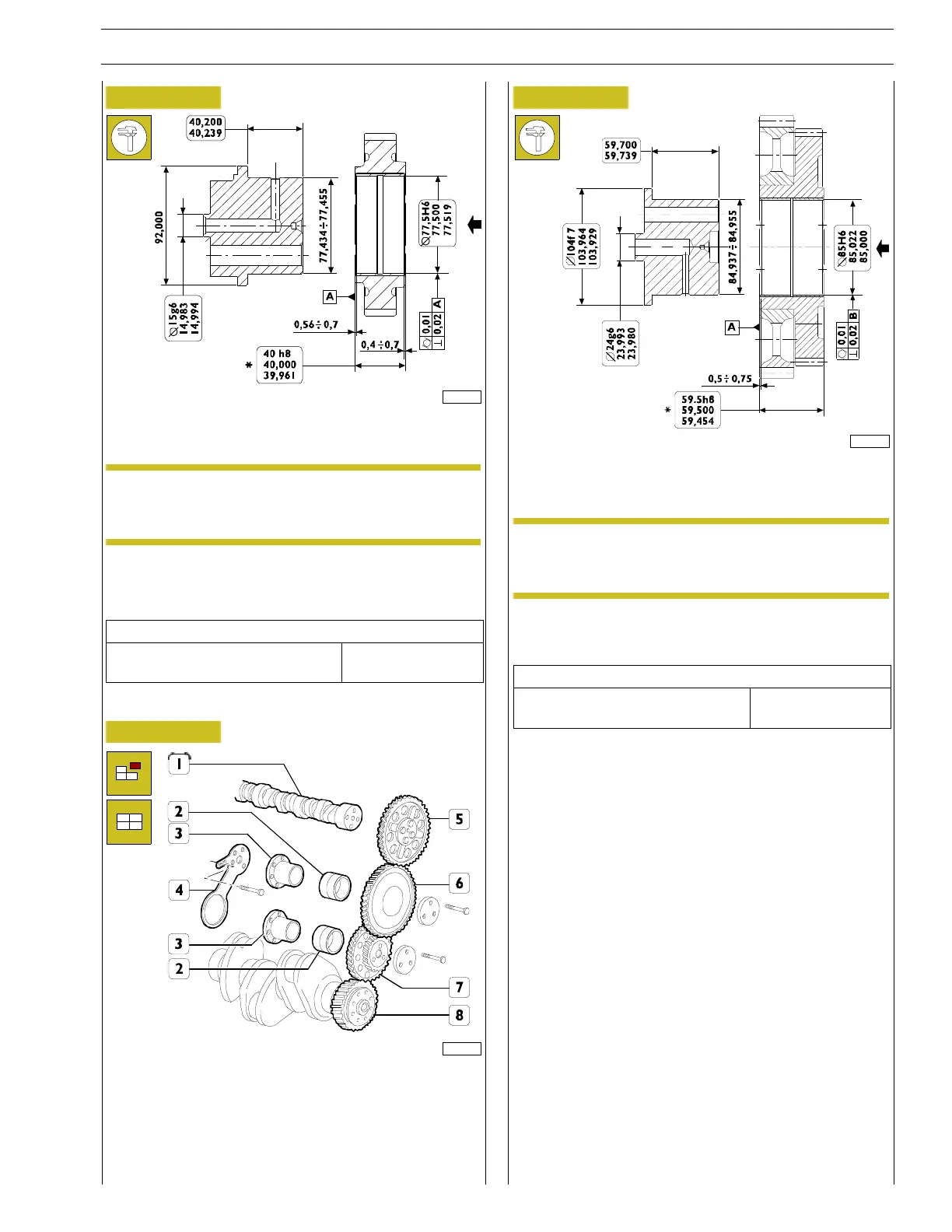

Figure 127

225003

After driving the bushing, bore it to obtain the diameter shown

in the figure.

NOTE The bushing must be driven into the gear in the

direction of the arrow setting the latter to the

dimension shown.

Check that the nominal assembly clearance between gear

bushings and pins is equal to the value stated below.

Technical data

rated assembling clearance

between gear bushings and pins

0.045 - 0.085 mm

Checking cam lift and camshaft pins alignment

Loading...

Loading...