36

SECTION 5 - REMOVAL - REFITTING OF THE MAIN ENGINE COMPONENTS

CURSOR SERIES

Base - 03/2015 Print P4D32C006 E

ELECTRO-INJECTOR

REMOVAL-REFITTING

Removal

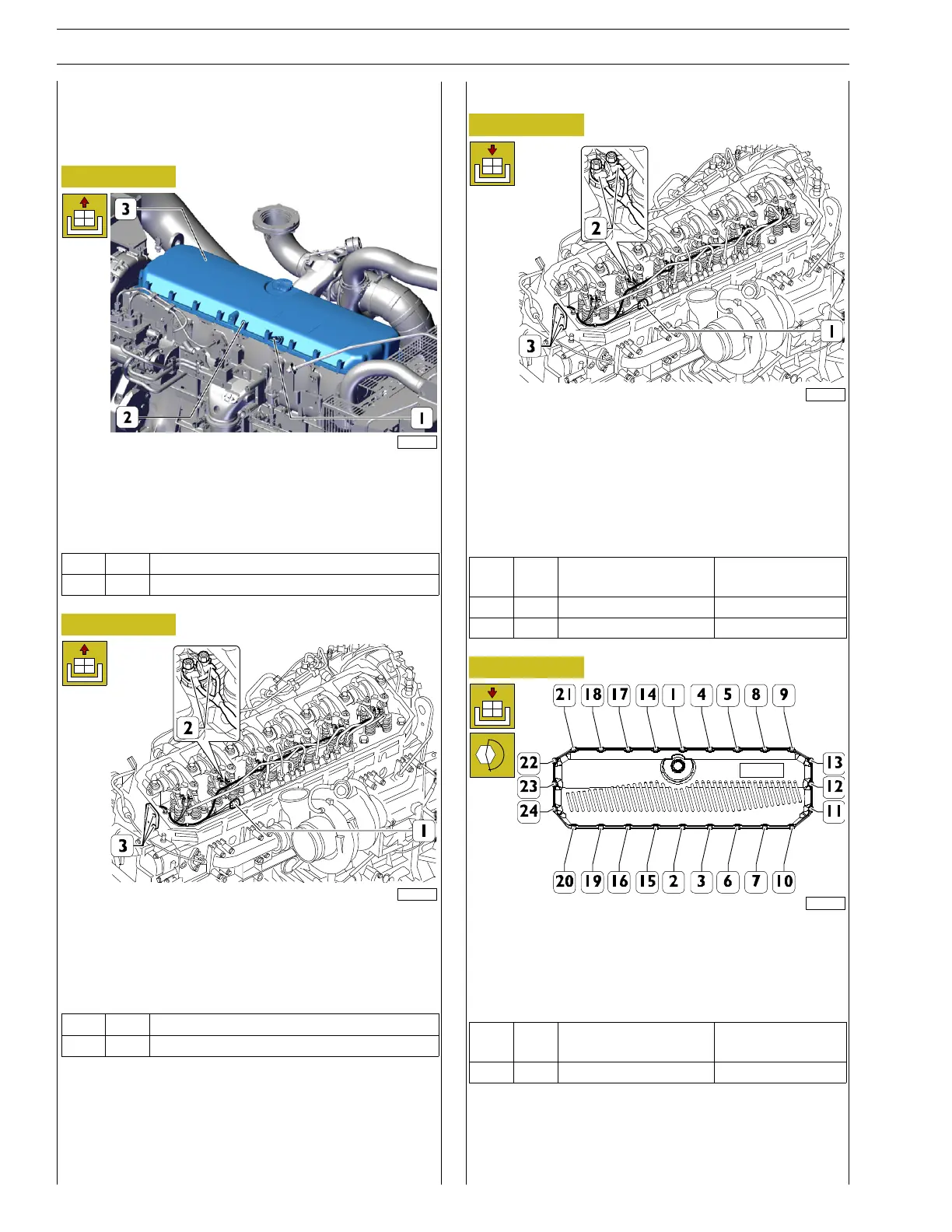

Figure 97

227771

Disconnect the electric connection of engine crankcase

pressure sensor.

Unscrew the fastening screws (2) and remove the tappet

cover (3) together with the gasket.

Ref.

No. Description

(2) 24 M6 x 1 screws

Figure 98

225049

Remove the wiring clamps.

Disconnect the connector from the rail pressure sensor (1).

Unscrew the nuts and disconnect the electrical connections

(2) from the injectors.

Ref.

No. Description

(2) 12 Nuts M4

Remove the screws (3) securing the connector and remove

all the wiring.

Refitting

Figure 99

225049

Position the wiring and secure it appropriately with clamps.

Connect the elctrical connections (2) to the injectors and

tighten the nuts to the torque indicated in the table.

Connect the connector from the rail pressure sensor (1).

Fasten the connects using the screws (3) and tighten them to

thetorqueindicatedinthetable.

Ref.

No. Description

Tightening

torques

(2) 12 Nuts M4 1.5 ± 0.25

(3) 4 Screws 8±2

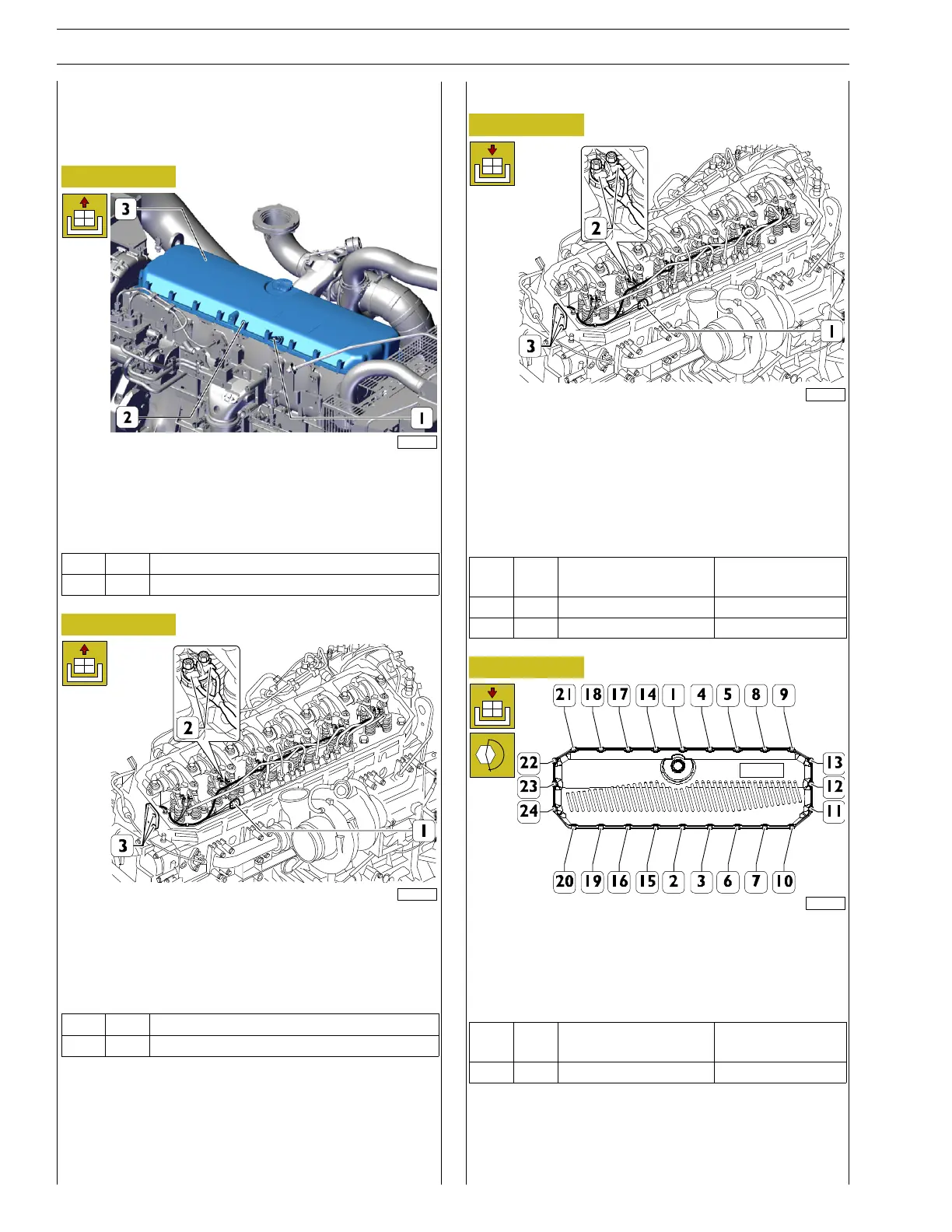

Figure 100

221122

Position the cover and new gasket and insert all the screws.

Replace the screws in the sequence 1-10-20-21-9 and then in

thesequenceshowninthefigureuntilcontact.

Tighten the screws (1-24 ) to the torque specified in the table.

Ref.

No. Description

Tightening

torques

(-) 24 M6 x 1 screws 8.5±1.5Nm

Connect the electric connection of engine crankcase pressure

sensor.

Loading...

Loading...