SECTION 6 - GENERAL MECHANICAL OVERHAUL

23

CURSOR SERIES

Print P4D32C006 E Base - 03/2015

CRANKCASE ASSEMBLY CHECKS

Crankcase checks

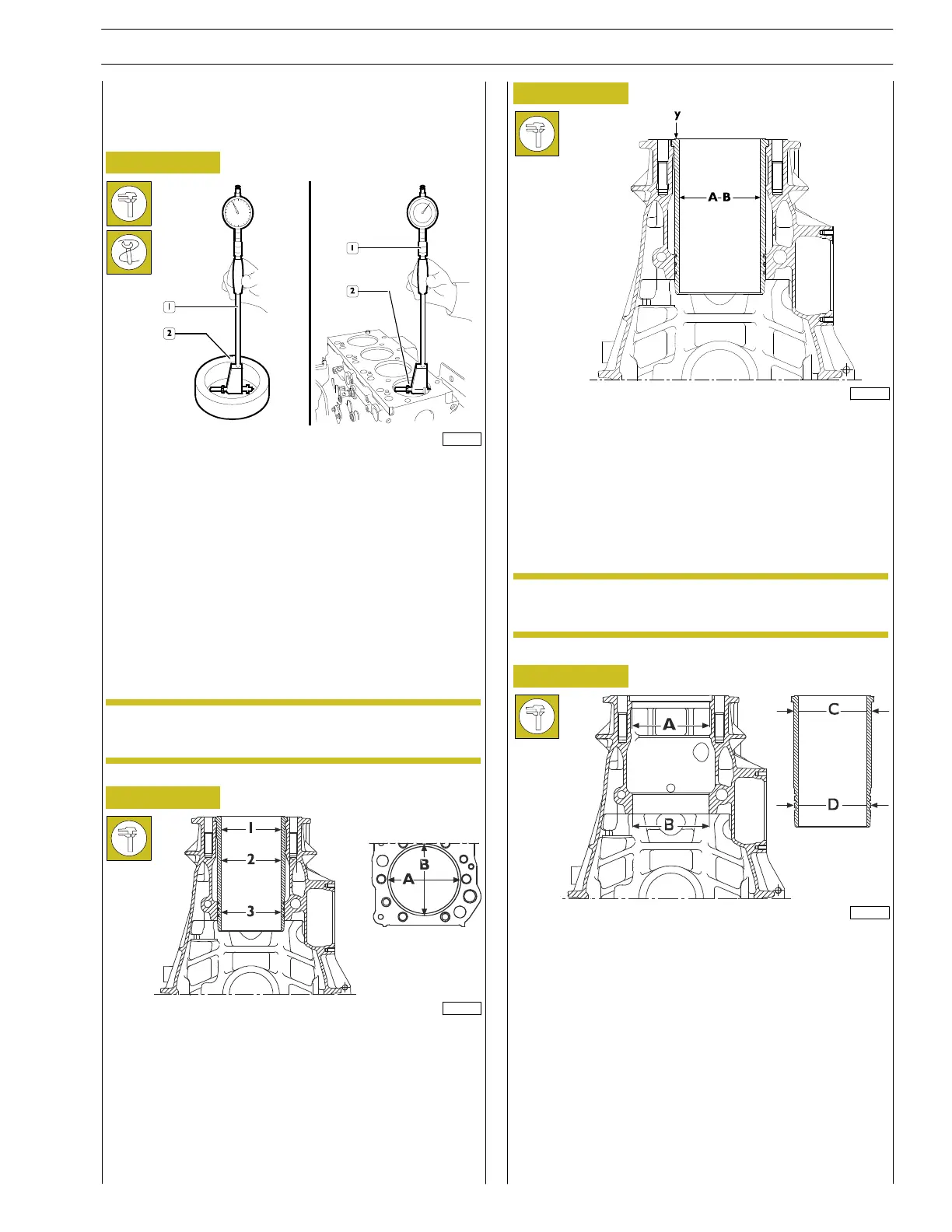

Figure 62

70166

After disassembling the engine, thoroughly clean the cylinder--

crankcase assembly.

Carefully inspect the crankcase for cracks.

Check the condition of casting hole plugs.

If the caps are rusted or there is any doubt over the efficiency

of the seal the produce, replace the caps with new ones.

During fitting operations, apply LOCTITE 270 to the caps.

The internal diameter of the cylinder liners is checked to ascer-

tain the extent of ovalization, taper and wear, using the bore

meter (2) fitted with a dial gauge (1) previously reset on the

ring gauge (3) of the diameter 135 mm.

NOTE If the 135 mm ring gauge is not available, use a

micrometer.

Figure 63

60596

1=1

st

measurement

2=2

nd

measurement

3=3

rd

measurement

Measurements should be carried out for every single cylinder

liner at three different heights and on two (A-B) perpendicular

plane levels as shown in the figure.

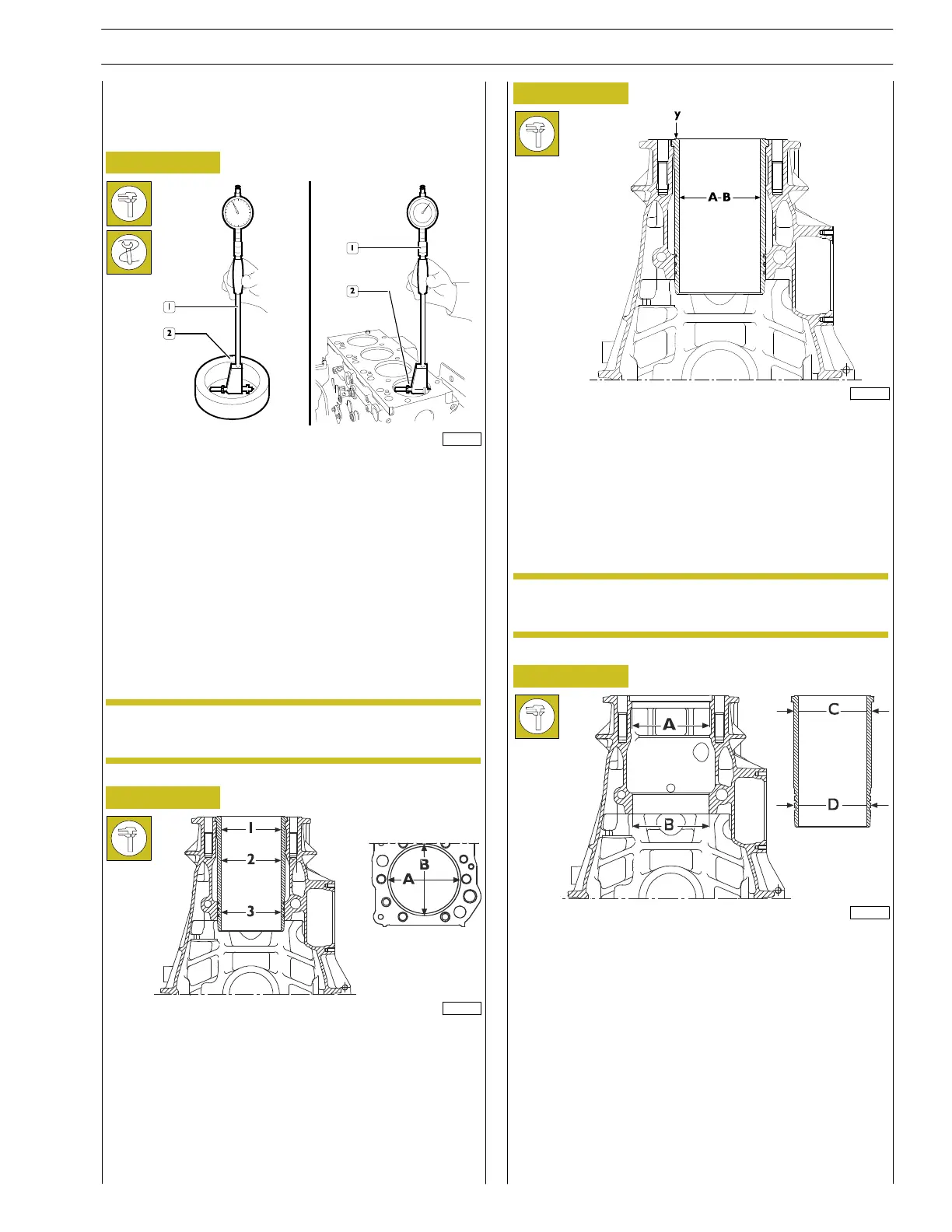

Figure 64

60595

A = Selection class 135.000 - 135.013

B = Selection class 135.011 - 135.024

Y = Marking area

When wear is over 0.150 mm or maximum ovalisation is 0.100

mm compared to the values shown in the figure, replace the

cylinder liner since it is not possible to adjust, lap or dress it.

NOTE Cylinder liners are equipped with spare parts

belonging to selection class ”A”.

Figure 65

60597

A= 153.500 - 153.525

B= 152.000 - 152.025

C= 153.461 - 153.486

D= 151.890 - 151.915

The illustrated diagram refers to the outer diameters of cylin-

der liners (C) and (D) and the inner diameters of their seats

(A) and (B).

Loading...

Loading...